Mounting – Grain Systems PNEG-526 User Manual

Page 139

SECTION A CONTENTS

Mounting

A-2

Allowable Oil Viscosity

A-9

General Construction

A-3,4

A-9

Lubrication

A-5-10

Forced Lubrication

A-9

Grease Units

Oil Level Dimensions

A-10

Designated Greases

A-7

Bearings, Oil Seals Gaskets

A-11-13

Grease Replenishment Change

A-7

Dissassembly, Assembly

Quantities of Grease

Daily Inspection

A-16

Oil Units

A-8

-

10

Ordering Correct Replacement Units Parts

. . .

A-16

Oil Fill Procedure, Oil Gauge

Storage &Operation After Storage

A-16

Standard Oils

A-8

Trouble Shooting

A-17

Oil Quantities

A-9

Notes

A-18

Mounting

1.

Mounting on Exact Planes

The Horizontal Type oil-lubricated units must be

mounted on horizontal surfaces. Where they are

mounted on inclined surfaces, some modifications may

be

Specify mounting plane inclination at time

of ordering.

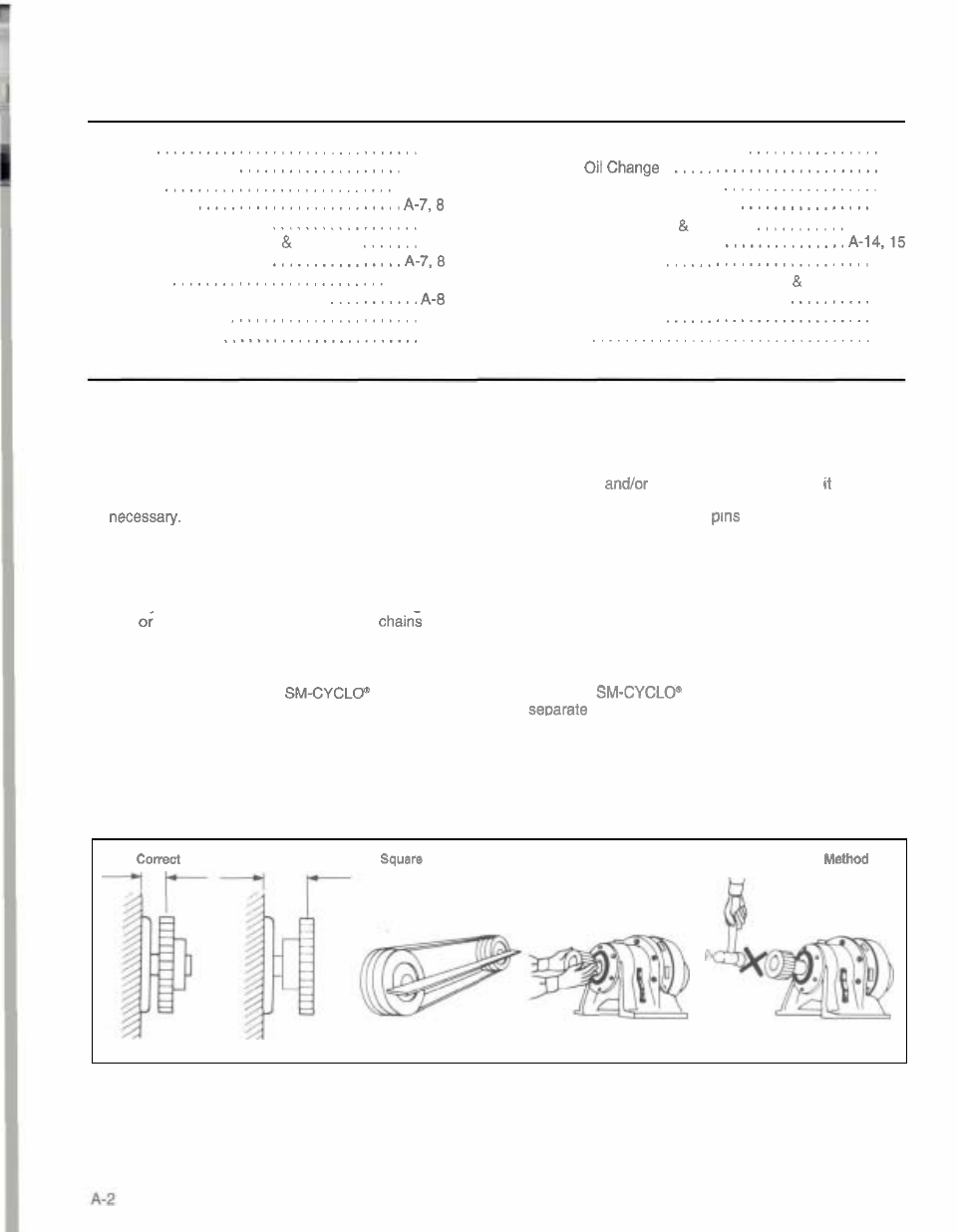

2. Accurate Alignment

Where the reducer is connected to the motor and the

driven machine through couplings, align the shafts

accuratelv. Where the reducer is connected through V

pulleys

sprockets, insure that the belts or

are

neither too tight nor too slack.

3.

Overhung Load Positions

Overhung loads should be located as close to the

bearing as possible. (See the

6000 Series

Catalog page E-8.)

4. Foundations

Foundations must be rugged enough to withstand shock

and stress applied from the load side through the

reducer.

5. Secure Housing

Where the reduction units are operated under conditions

of vibration

frequent starts and stops, is

recommended to secure them on their mounting

surfaces by inserting dowel

into the knock-holes

provided on the foot of the casing. This will insure that

bending or shearing forces are reduced on the mounting

bolts. Pins must be securely inserted, particularly when

the units are to be operated under conditions of severe

recurrent peak loads.

6.

Mounting Accessibility

The reduction units must be mounted in locations with

easy accessibility for lubrication maintenance purposes.

7. Ventilation

When the

Speed Reducer is mounted in a

enclosure, be sure that adeauate ventilation is

provided.

Incorrect

And Parallel

Correct

Method

Incorrect

Reducer

Wall

Reducer

Wall