Lubricants, Grease lubricated models, Replenishment and change guidelines – Grain Systems PNEG-526 User Manual

Page 144

Lubricants

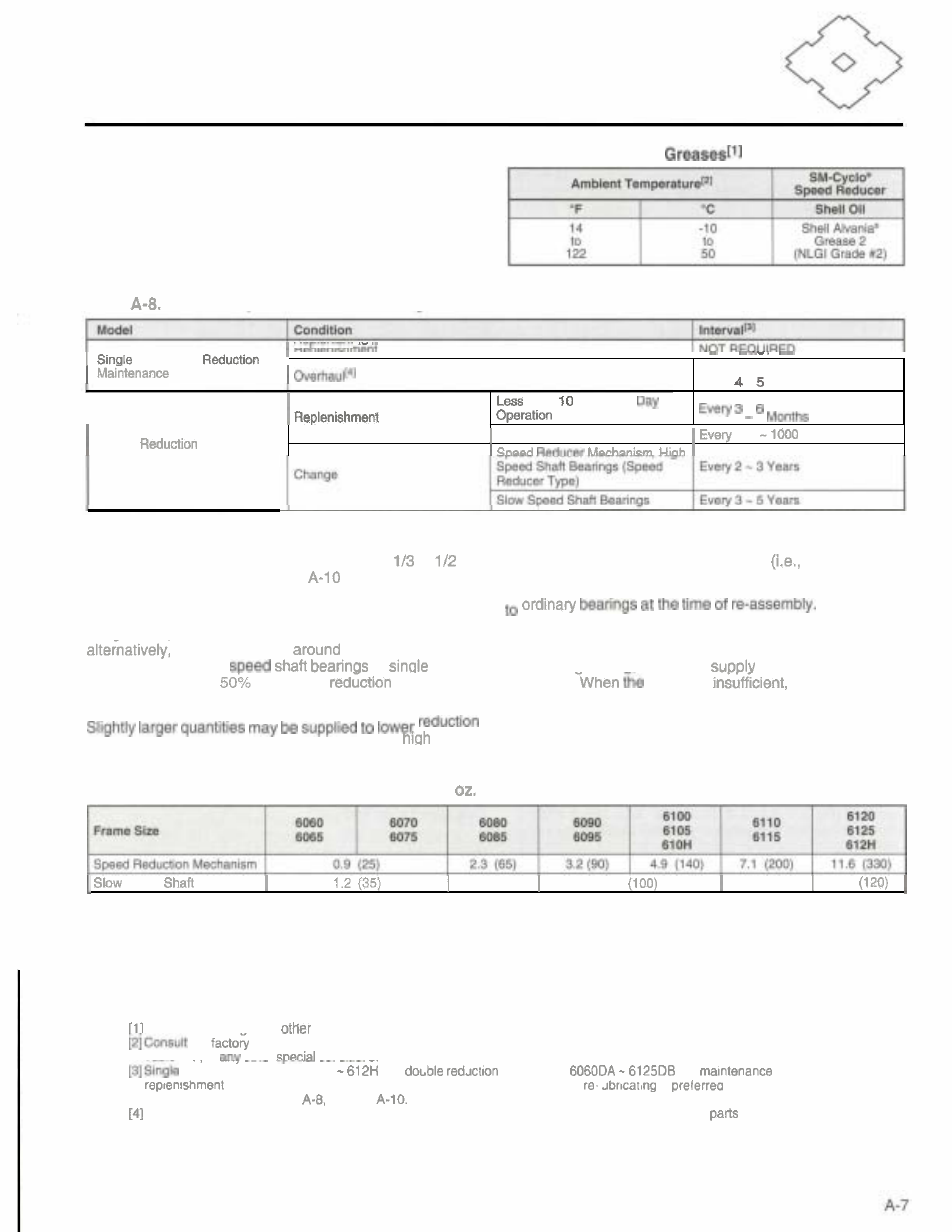

Table A-7. Standard

Grease Lubricated Models

Those models listed in Tables A-3

-

A-6 as grease

lubricated are filled with grease before shipment to the

customer and are ready for use.

Table

Grease Replenishment and Change Interval

Free

Type

Double

10

-

24 Hours Per Day Operation

500

. . . . .

.

Every

20,000

Hours

or

Every

-

Years

and

Double

Replenishment and Change Guidelines

Replenish grease to the reduction mechanism

to

of

Apply grease liberally to the central pan

around the

the quantity listed in Table A-9 or

for the first reduction

eccentric bearings) of the mechanism. Apply grease to both

stage at the interval recommended in Table A-8.

the slow speed and high speed shaft bearings as you would

When the unit is disassembled for overhauling, refill with

the grease quantities indicated in Table A-9 or A-10. Or

If excessive grease is added, agitation heating of the grease

80%

of the space

the reduction

will raise theoperating temperature of the unit. Avoid-

mechanism and slow

of

excessive areasina. but do not

an insufficient amount

Than

Hours

Per

reduction units, and

around the

mechanism

of grease.

grease is

it will raise the

of both the first and second stage of double reduction units.

unit's operating temperature due to breakdown of the

lubrication films on the eccentric bearing. In this case, if the

ratio units, and somewhat smaller auantities for

operating temperature rises, supply grease immediately.

reduction ratio units.

Table

A-9. Single Reduction Grease Quantities

-

(g.)

Speed

Bearing

2.5 (70)

3.5

3.2 (90)

4.2,

Notes:

Avoid the use of arease

than shown in Table A.7.

the

when the drives are used

Table

A-7 or

other

conditions

under widely fluctuating temperatures, ambient temperatures other than those listed in

.

reduction frame sizes 6060

ana

frame sizes

are

free units. Grease

is not necessary. Wnere longer life of the ar ve is expected or

if

is

before the recommendea

interval, refer to Tables A-7,

A-9 and

Overhauling consists of disassembling the unit, replacing the seals and gaskets, cleaning the internal

and then repacking the unit

with designated grease.