Auxiliary signal switches, Field installation instructions, Corporation – Grain Systems PNEG-526 User Manual

Page 121: Industrial combustion equipment and valves, Fig. 1, Fig. 2, Fig. 3, Fig. 4, Wand position mounting brackets

m

CORPORATION

MUNCIE, INDIANA, USA

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

Auxiliary Signal Switches

Field Installation Instructions

NOTE: Instructions below are written for normally

closed valves. For normally open versions (STO-

M, STO-A, Fig. 1 & 2), reverse switch nomencla-

ture. (VOS becomes VCS and vice versa.)

General: Shut off fuel supply upstream of valve, then

de-energize valve electrically.

– Remove top or side cover to provide access, being

careful not to damage gasket.

– Compare with illustrations at right to identify YOUR

valve type.

To replace existing switches:

– Note wand position and mounting hole location

carefully, then remove 2 screws and lift existing switch.

– Install replacement switch in same mounting holes on

bracket and verify correct wand position.

– Replace existing wiring one connection at a time,

following original route and placement.

To add switches to existing valve:

– Check illustrations at right. If your valve uses a switch

mounting bracket as in Fig. 1 & 2, mount switches to

bracket using the mounting holes appropriate for valve

type and size.

– Position bracket so VCS wand just touches top of

actuator, then move downward slightly, depressing

wand until switch clicks, then tighten mounting screws

to hold this position.

– Pin bracket by drilling 1/8" dia. holes 1/4" deep into

bracket mounting pad through drive pin holes, then tap

drive pin in until flush.

– Route wires to wiring compartment as shown, then

complete wiring connections and clean out metal

drilling chips from previous procedure.

– Cycle valve, checking switch actuation points carefully.

(VCS actuates at top of stem stroke, VOS at bottom.)

Simultaneously the valve body must be tested for

switch continuity and seat leakage. Bend VOS switch

wands slightly if necessary to insure valve is opening

fully.

– Replace gasket and cover, then return valve to

service.

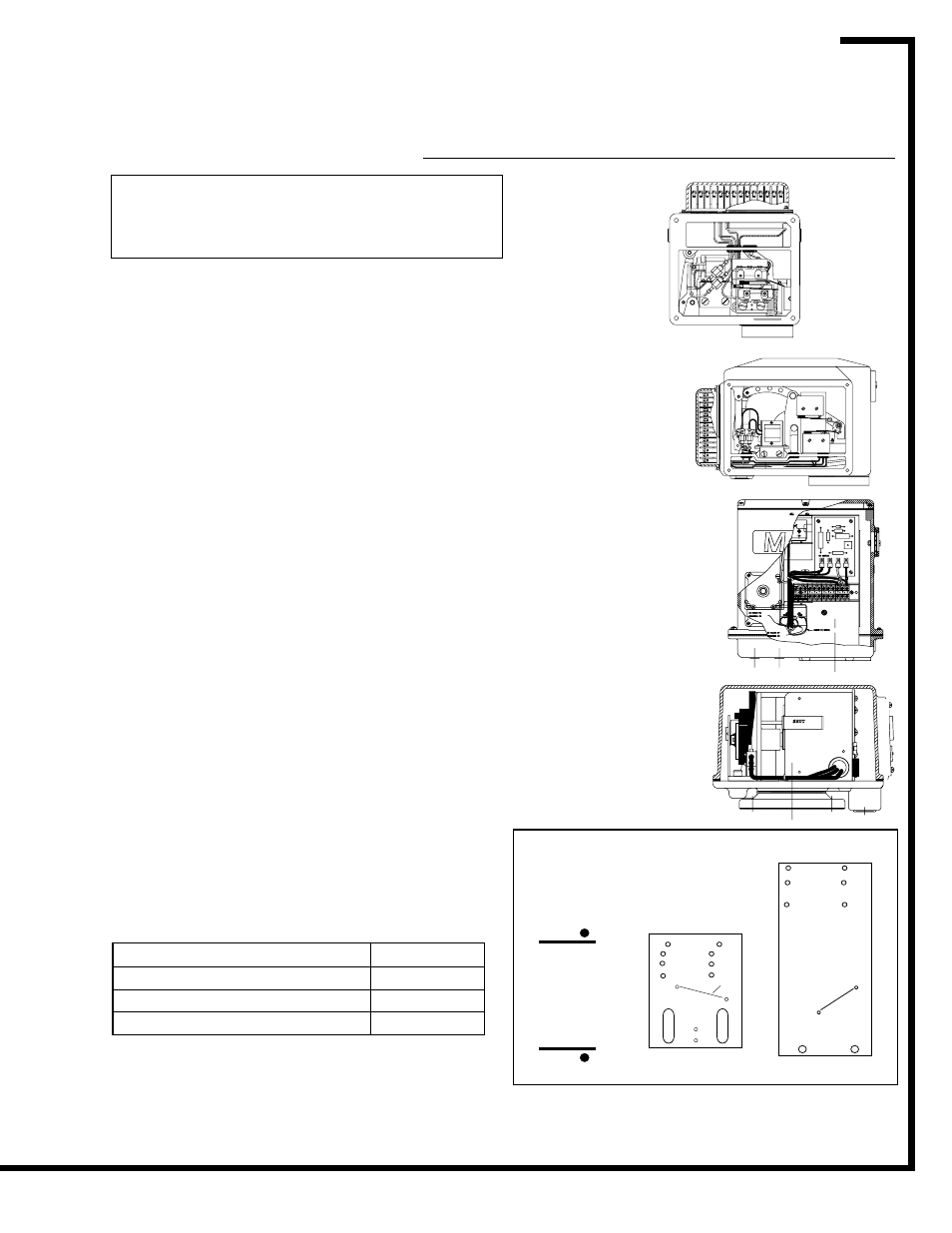

Fig. 1

.75" – 3"

non-CP

Remove

side cover plate.

Switches mount

on bracket. (See

"A" below)

Fig. 2

2.5" – 4" -CP

6" 808

Remove

side cover plate.

Switches mount

on bracket. (See

"B" below)

1/00

Page 6100-S-7

Electro-Mechanical Valves

Fig. 3

4" – 6" 7000

Remove 2-piece top cover.

Switches mount on support

stand.

Fig. 4

.375" – .75" 8700

Remove top cover.

Switches mount on actuator

frame

VOS switch

on front

VOS switch wand

should be actuated

from above.

VCS switch wand

should be actuated

from below.

Oil SOV &

2"-6" Gas

Bracket

Mounting

Slots

Drive

Pins

VCS switch mounts

on back of bracket

VOS switch

on front

1-1/2"

3/4", 1"

1-1/4"

A

For 1", 1.25" C.I.

& 2", 3" non-CP

Wand Position

Mounting Brackets

3",4",6"(-2)

3",4",6"(-2)

2-1/2"(-2)

2-1/2"(-1)

VCS Switch

on back

Bracket

Mounting

Holes

B

r

e

v

o

C

)

s

b

l

-

t

f

(

e

u

q

r

o

T

r

e

v

o

C

r

o

t

a

r

e

p

O

4

2

-

0

1

#

5

2

s

r

e

v

o

c

s

s

e

c

c

a

r

e

h

t

o

ll

A

0

2

-

"

5

2

.

0

5

e

t

a

l

P

r

e

v

o

C

s

s

e

c

c

A

d

e

d

n

e

t

x

E

0

2

-

"

5

2

.

6

9

NC

COM

#1 BLACK TO

#3 BLACK TO

BLACK TO MOTOR

TERMINAL #1

TERMINAL #3

NO

1

2

12

11

10

9

8

7

6

5

4

3

2

1

TO CLUTCH

SHUT