Inspection and maintenance of gas ports, Burners – Grain Systems PNEG-526 User Manual

Page 108

m

CORPORATION

MUNCIE, INDIANA, USA

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

Page 5550-S-12

Series NP-LE AIRFLO

®

Burners

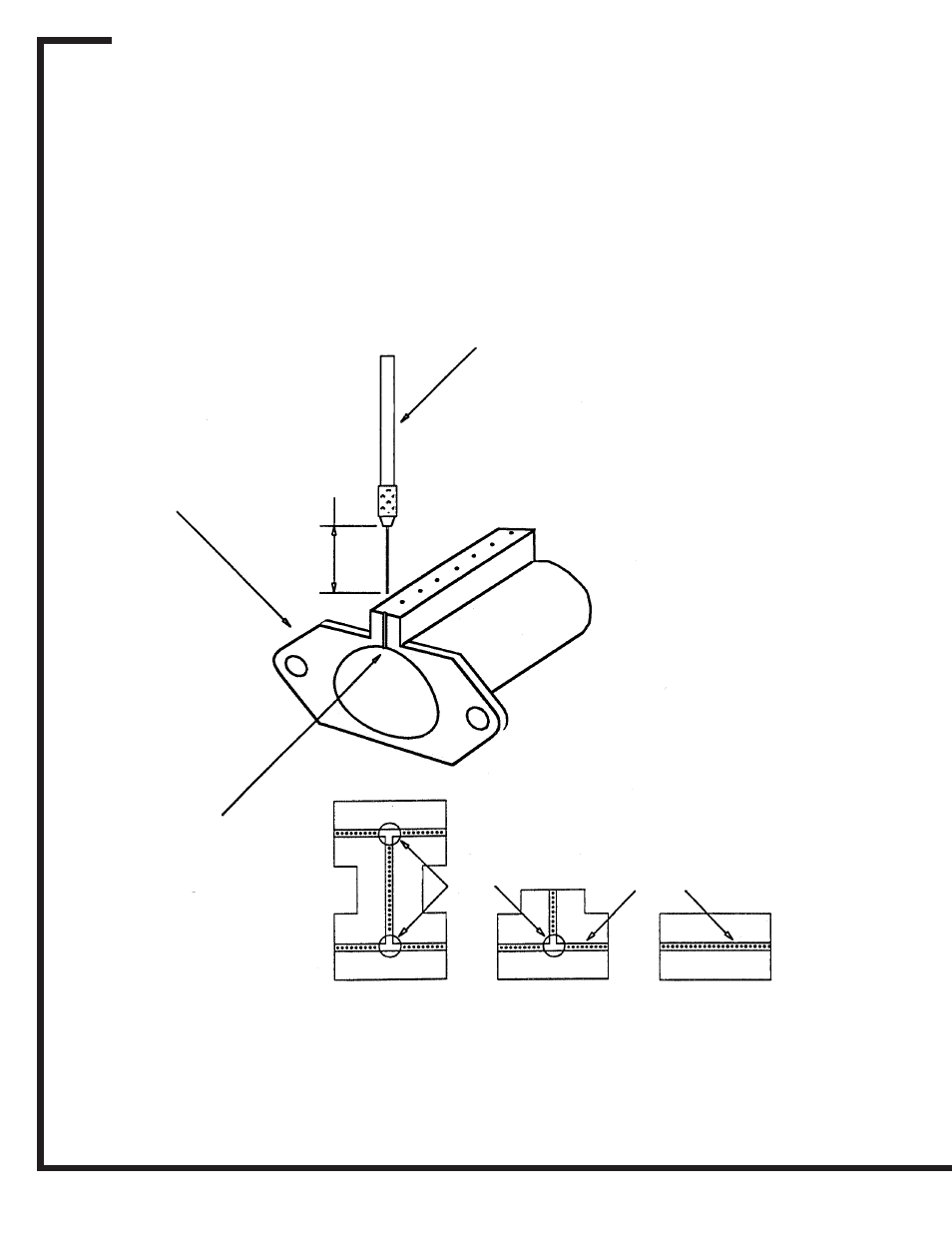

Inspection and Maintenance of Gas Ports

– Conduct initial inspection within the first month

after commissioning. Visually check the gas ports

of new burner assemblies for any piping scale or

debris. Use Pin Vise with drill bit to remove.

– Annual inspections are normally adequate once

the initial piping debris is removed. The operating

conditions of the burner will determine how

frequently maintenance is actually required.

– Use of an electric drill motor is not suggested

unless both Pin Vise and Drill (as shown below)

can be chucked up in a vari-speed drill unit. Use

caution, because it is easy to snap the bits off in a

port when using a drill motor. Removal of broken

bits from the gas ports is difficult.

– Contact your Maxon representative to answer

questions or address any problems.

NP-LE AIRFLO®

Burner Body

(Mixing Plates Not Shown)

1 inch

Gas Ports

All are #43 Drill Size

(Exception is several #47

holes at the intersection of

12x6 tee's and 36 BI's)

Pin Vise

36" BI Sections

12" x 6"

Tee Sections

All Straight Sections

6", 12", 18" & 24"

#47

Holes

Here

#43

Holes