Lubrication, Oil lubricated models – Grain Systems PNEG-526 User Manual

Page 145

LUBRICATION

Table

A-10.

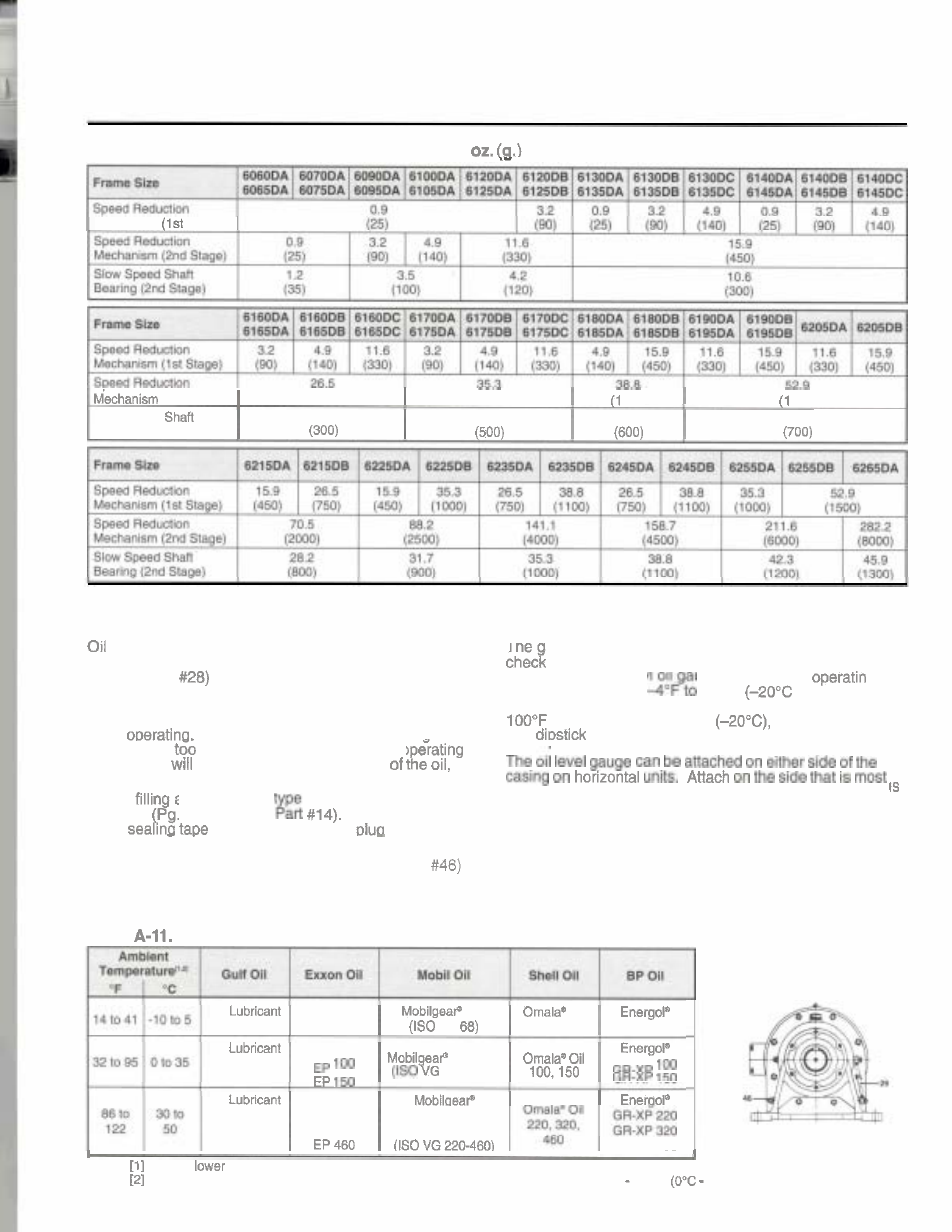

Double Reduction Grease Quantities

-

.

Mechanism

Stage)

(2nd Stage)

(750)

(1000)

100)

500)

Slow Speed

10.6

17.6

21.2

24.7

Bearing (2nd Stage)

Oil Lubricated Models

Oil Fill Procedure

Oil Level Gauge

lubricated models are not filled with oil prior to shipping.

The auge must be replaced when it becomes difficult to

Before start-up, remove the oil fill plug (See Pg. A-3,

the oil level due to discoloration of the vinyl hose.

Fig. A-2, Part

and fill the reducer with recommended

Use the standard vinyl oil auge for a reducer

in

oil. Refer to Tables A-11-A-14 for standard oil, allowable

ambient temperature

100°F

to 40°C). &here

viscosity, quantity, and change interval. The oil level must

the reducer is used at ambient temperatures greater than

be to the upper red line on the oil level gauge while the unit

(40°C) or less than -4°F

a glass gauge set

is not

and above the lower red line durina

or a

is recommended.

operation. If

much oil is supplied, the unit's o

temperature

rise due to the churning heat

or

oil will leak across the high speed shaft oil seal.

convenient for checking the oil level. (The oil level gauge

Before

a vertical base pe unit with oil, remove the

usually attached on the right side when viewed from the

vent plug

A-3, Fig. A-2,

After filling, apply

slow speed shaft end.)

teflon

to threads of the vent

before

.

installing.

When draining oil, remove drain plug (Fig. A-5, Part

or

lower side plug of the oil level gauge.

Table

Standard Oils

EP

Spartan'

626

Oil

HD 68

EP 68

VG

68

GR-XP 68

EP

Spartan'

HD 100

627,629

HD 150

100.150)

EP

Spartan"

HD 220

EP 220

630,632

HD 320

EP 320

633,634

HD 460

GR-XP 460

Fig.

A-5

I

I

Notes:

Use the

viscosity oil specified for each ambient temperature range for use in winter or relatively low ambient temperatures,

Please consult the factory for consistent use

in ambient temperatures other than 32°F 104°F

40°C).

A-8