Grain Systems PNEG-526 User Manual

Page 134

BIM 1020/2005/03

6

www.nord.com

MAINTENANCE

Mineral lubricant should be changed every 10,000 service hours or after two years. For synthetic oils, the lube should be changed every

20,000 service hours or after four years. In case of extreme operating (e.g. high humidity, aggressive environment or large temperature

variations), shorter intervals between changes are recommended.

OIL SPECIFICATIONS

NORD supplies aII reducers fiIIed with oiI from the factory. Consult the sticker adjacent to the fill plug to determine the type of lubricant

installed at the factory. Standard lubricant is ISO VG220 mineral-based oil. However, some units have special lubricants designed to operate

in certain environments or to extend the service life of the lubricant. If in doubt about which lubricant is needed, contact NORD Gear.

STANDARD OIL – ISO VG220

Ambient Temperature

FormuIation

20 to 104

qF (-5 to 40qC)

MineraI

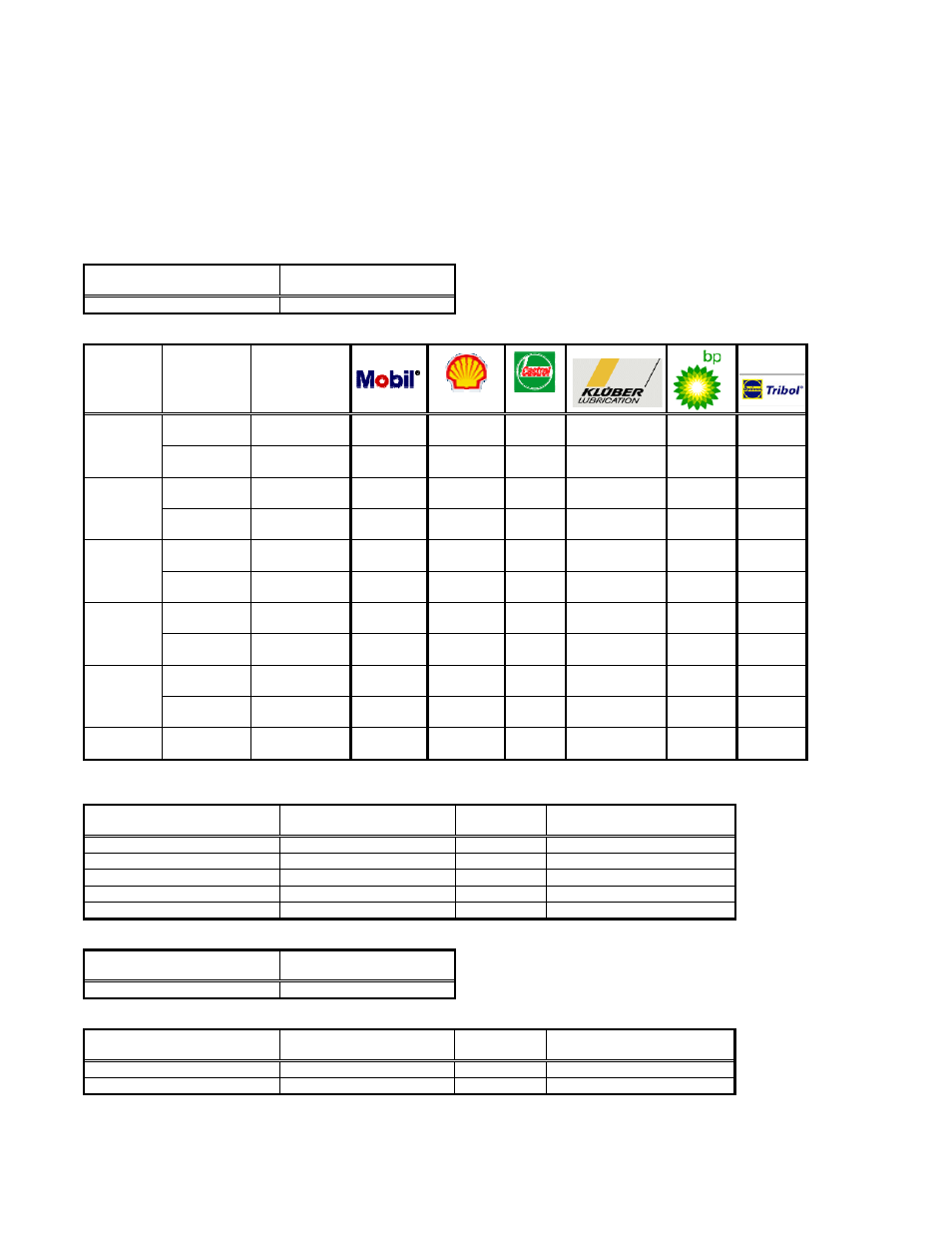

TYPICAL OILS

Viscosity

ISO NLGI

Formulation

Service

Temperature

Range

Shell

Castrol

Conventional

Mineral

20

qC to +50qC

68F to +122

qF

Mobilgear

634

Omala

460

7EP

Klüberoil

GEM 1-460

Energol

GR-XP 460

Tribol

1100/460

VG 460

Synthetic

PAO

-30

qC to +80qC

-22

qF to +176qF

Mobil

SHC 634

Omala

460 HD

Isolube

EP 460

Klübersynth

EG 4-460

N/A

Tribol

1510/460

Conventional

Mineral

0

qC to +30qC

32

qF to +86qF

Mobilgear

632

Omala

320

6EP

Klüberoil

GEM 1-320

Energol

GR-XP 320

Tribol

1100/320

VG 320

Synthetic

PAO

-35

qC to +80qC

-31

qF to +176qF

Mobil

SHC 632

Omala

320 HD

Isolube

EP 460

Klübersynth

EG 4-320

N/A

Tribol

1510/320

Conventional

Mineral

-5

qC to +40qC

+20

qF to +104qF

Mobilgear

630

Omala

220

5EP

Klüberoil

GEM 1-220

Energol

GR-XP 220

Tribol

1100/220

VG 220

Synthetic

PAO

-34

qC to +80qC

-30

qF to +176qF

Mobil

SHC 630

Omala

220 HD

Isolube

EP 220

Klübersynth

EG 4-220

N/A

Tribol

1510/220

Conventional

Mineral

-15

qC to +25qC

5

qF to +77qF

Mobilgear

629

Omala

100

4EP

Klüberoil

GEM 1-150

Energol

GR-XP 100

Tribol

1100/100

VG 150

&

VG 100

Synthetic

PAO

-37

qC to +10qC

-35

qF to +50qF

Mobil

SHC 629

Omala

150 HD

Isolube

EP 150

Klübersynth

EG 4-150

N/A

N/A

Conventional

Mineral

-15

qC to +25qC

5

qF to +77F

Mobilgear

626

Omala

68

2EP

Klüberoil

GEM 1-68

Energol

GR-XP 68

Tribol

1100/68

VG 68

Synthetic

PAO

-40

qC to +10qC

-40

qF to +50F

Mobil

SHC 626

N/A

Isolube

EP 68

N/A

N/A

N/A

VG 32

Synthetic

PAO

-40

qC to +10qC

-40

qF to +50qF

Mobil

SHC 624

N/A

N/A

Klüber-Summit

HySyn FG-32

N/A

N/A

PAO = Poly Alpha Olefin

SPECIAL PURPOSE LUBRICANTS

Ambient Temperature

FormuIation

Manufacturer

Oil Brand Name

20 to 104

qF (-5 to 40qC)

Food Grade Oil - Synthetic

Chevron

FM ISO 220

20 to 104

qF (-5 to 40qC)

Food Grade Oil - Synthetic

OilJAX

MagnapIate 85W140-FG

5 to 125

qF (-20 to 50qC)

FIuid Grease

MobiI

MobiIux EP023

-30 to 140

qF (-35 to 60qC)

FIuid Grease - Synthetic

MobiI

MobiIith SHC 007

-30 to 140

qF (-35 to 60qC)

FIuid Grease - Synthetic

SheII

Albida LC

STANDARD BEARING GREASE – NLGI 2EP Lithium

Ambient Temperature

FormuIation

-20 to 140

qF (-30 to 60qC)

MineraI

OPTIONAL BEARING GREASES

Ambient Temperature

FormuIation

Manufacturer

Grease Brand Name

-40 to 230

qF (-40 to 110qC)

Synthetic

SheII

AerosheII 6

-40 to 230

qF (-40 to 110qC)

Food Grade - Synthetic

LubripIate

SFL1