The burner modes, The burner, Appendix a: grain drying operations – Grain Systems PNEG-1851 User Manual

Page 79

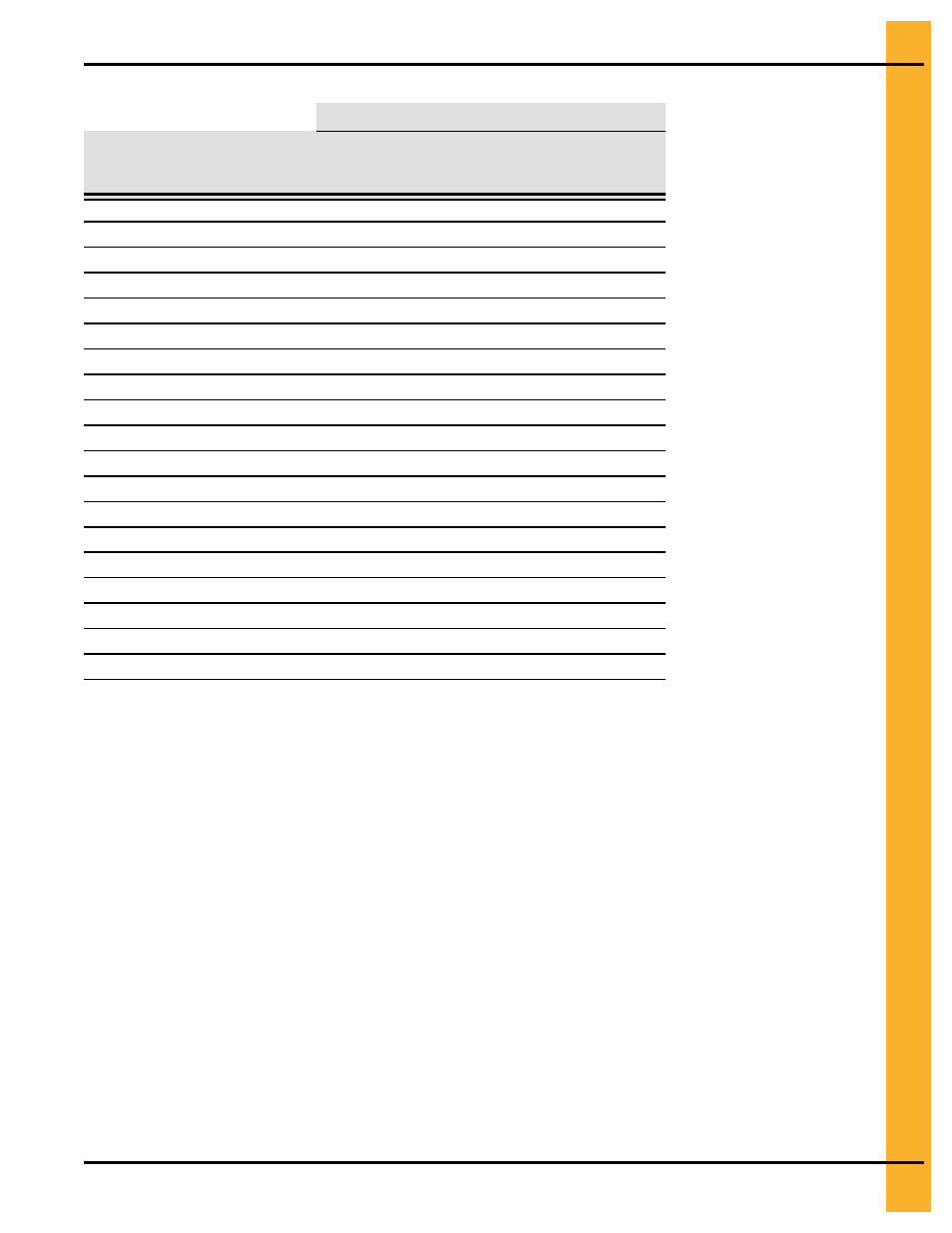

Appendix A: Grain Drying Operations

Table A-2 Initial settings for the dry and cool operation

Unload speed in manual mode

Initial

moisture

Drying time

(min.)

One-module

dryer (Bph)

Two-module

dryer (Bph)

Three-

module dryer

(Bph)

17%

18

360

890

990

18%

24

270

670

910

19%

30

220

540

730

20%

35

190

460

620

21%

40

160

400

540

22%

45

140

360

480

23%

50

130

320

440

24%

55

120

290

400

25%

60

110

270

360

26%

65

100

250

330

27%

70

90

260

310

28%

75

90

210

290

29%

80

80

200

270

30%

85

80

190

260

31%

90

70

180

240

32%

95

70

170

230

33%

100

60

160

220

34%

105

60

150

210

35%

110

60

150

200

The Burner Modes

When heating the plenum, the burner modes help avoid high plenum temperatures and frequent fluctua-

tions. The chosen burner mode is dependent on the grain type and outside temperature.

Establishing a uniform plenum temperature is important, as it is the air in the plenum that is eventually

released into the drying chamber to dry the grain. As a result, frequent fluctuations in the plenum’s temper-

ature or temperature levels that are too high directly impact the quality of the grain. To help regulate the

temperature inside the plenum chamber, each available burner mode uses the plenum temperature set-

point and burner differential settings as reference parameters (see

Setting the Plenum Temperature

). It is the sum or difference of these two parameters that determine whether the burner

operates in low fire or high fire, or in some instances, shuts off. The available burner modes are shown in

the table that follows.

PNEG-1851 Vision N2

79