Staged batch based on grain temperature – Grain Systems PNEG-1851 User Manual

Page 49

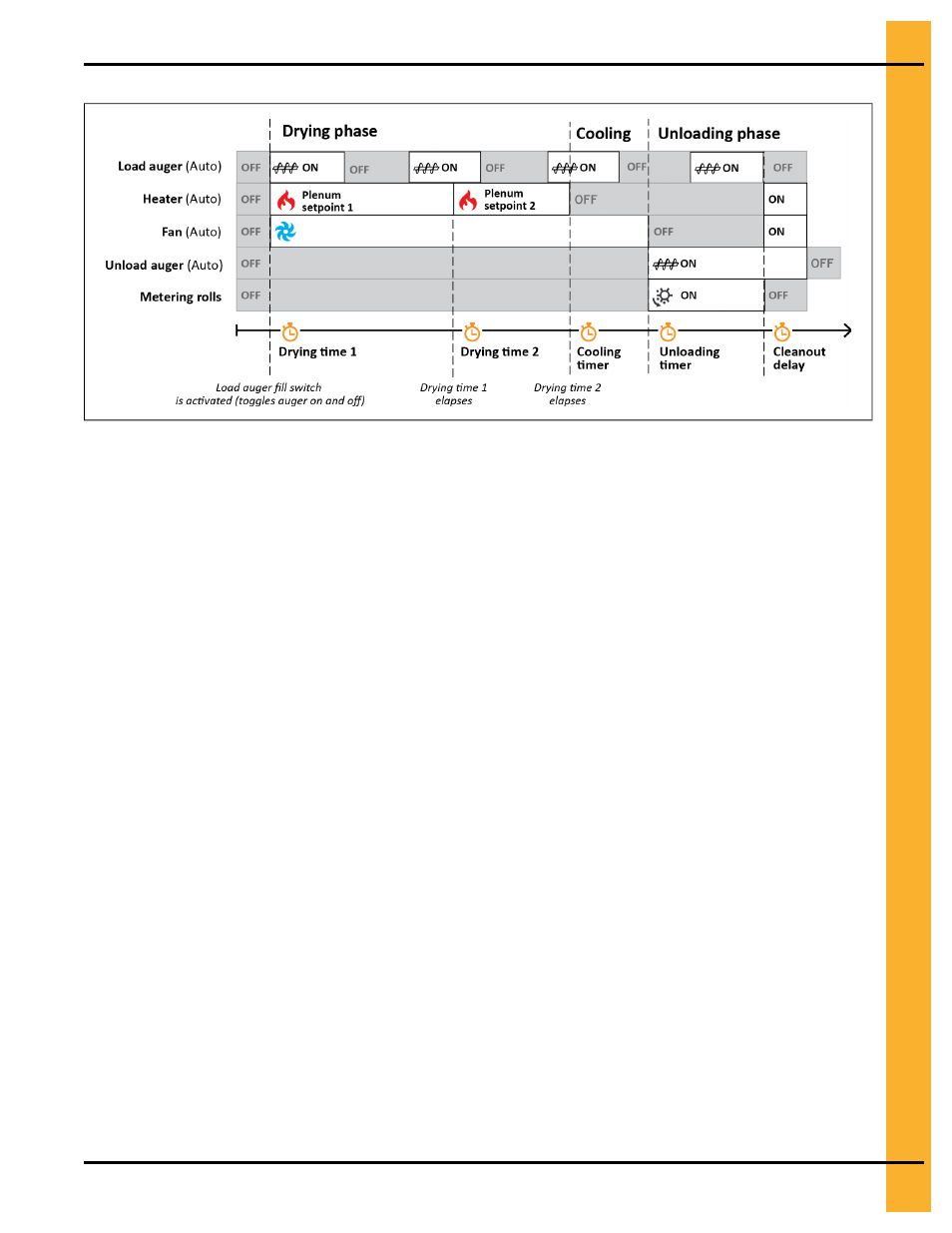

Figure 5-8 Dual-setpoint time control scheme in the dry and cool operation

NOTE: In full-heat operation, the cooling phase is simply bypassed. As a result, the unloading phase

starts immediately following the drying phase, allowing uncooled, hot grain to be discharged from

the dryer.

Staged Batch Based on Grain Temperature

Temperature-based control schemes in staged batch use grain temperature sensors as their reference

parameter. Use these schemes when you would like the grain temperature to dictate the moisture content

and unload grain at a specific temperature.

How It Works

During the drying phase, all fans and heaters are activated so that the plenums can reach their respective

setpoints. The drying phase continues until the grain temperature reaches a defined temperature setpoint.

Once this setpoint is reached, the heaters stop, the drying phase ends, and then the cooling and unloading

phases follow one after the other.

To better control the grain’s final temperature, it is also possible to alter the plenum setpoint when the grain

temperature reaches a predefined temperature. By doing so, the wet grain is exposed to two different

drying temperatures within the same drying phase. The drying phase ends when the grain temperature

reaches its final temperature setpoint (see

The Dual-Setpoint Temperature Control Scheme, page 50

for

details).

The Temperature Control Scheme

In the temperature control scheme, you enter the following parameters:

• The grain temperature setpoint

• The temperature setpoint of each plenum

As shown in the following figure, the drying phase starts when the load auger fill switch is activated and

stops when the grain temperature reaches its setpoint. A cooling phase immediately follows, and the dry

and cool grain is then discharged from the dryer during the unloading phase.

PNEG-1851 Vision N2

49