Continuous flow based on grain temperature, How it works, The 1-speed control scheme – Grain Systems PNEG-1851 User Manual

Page 42

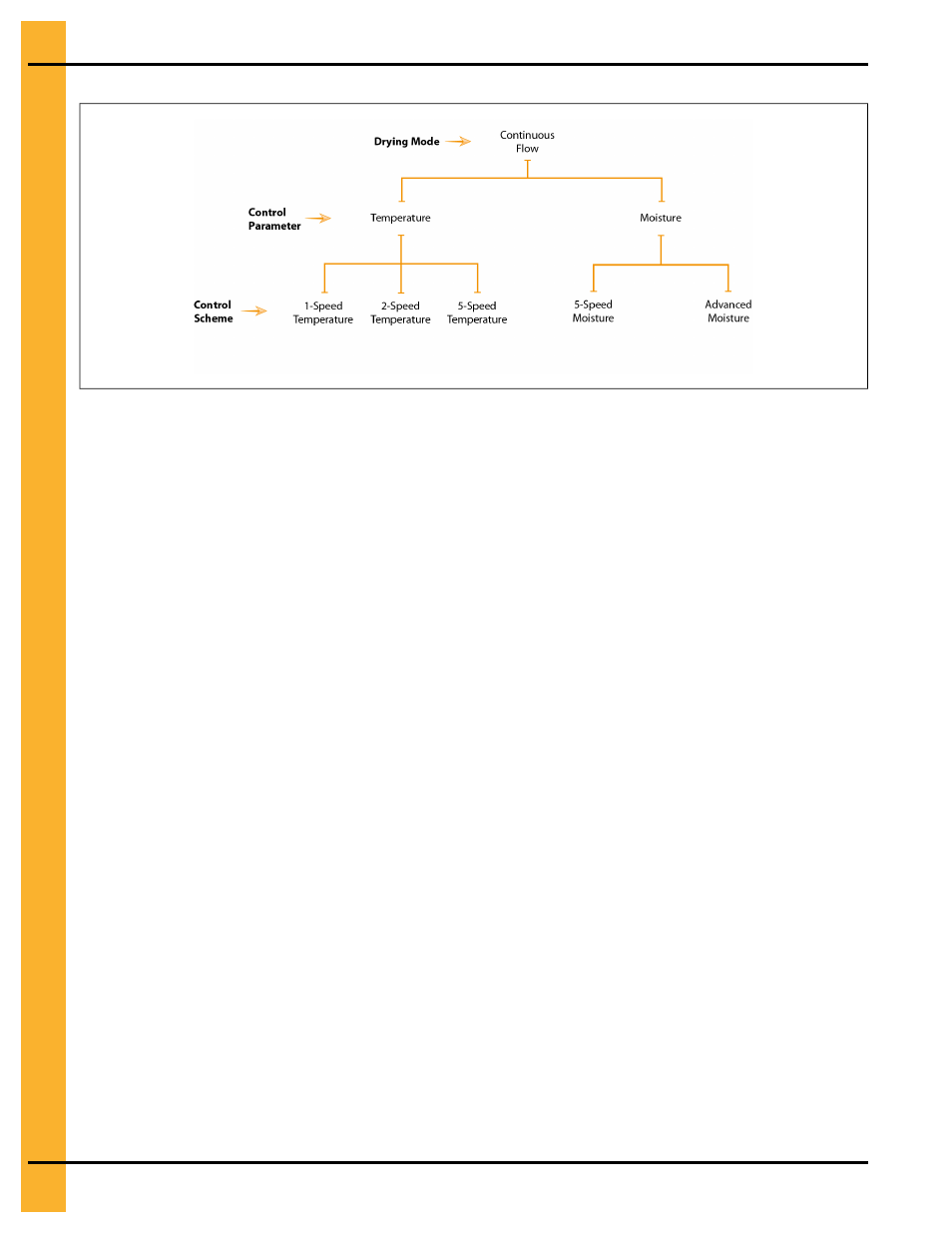

Figure 5-1 Breakdown of the control parameters and schemes in the continuous flow mode

Continuous Flow Based on Grain Temperature

Temperature-based control schemes in continuous flow use the grain temperature as their reference

parameter. As the grain temperature rises or drops, the unload speed automatically adjusts according to

the selected control scheme.

How It Works

Grain temperature is directly proportional to grain moisture. The unload rate changes to keep the grain

temperature constant, thus controlling the moisture output.

Let’s assume a grain temperature setpoint of 105°F. If the dryer reports a grain temperature reading of

110°F, the grain is five degrees higher than the target temperature. To correct this, the selected control

scheme automatically increases the unload speed, thereby reducing the length of time that the grain

spends in the grain columns. The opposite is also true. If the dryer reports a grain temperature reading of

100°F (five degrees below the setpoint), the unload speed automatically decreases.

The following three temperature-based control schemes are available in continuous flow mode:

• 1-speed

• 2-speed

• 5-speed

The 1-Speed Control Scheme

In the 1-speed control scheme, you enter the following parameters:

• The metering roll speed setpoint

• The grain temperature setpoint

As shown in the figure that follows, the metering rolls turn at the speed setpoint if the grain temperature is

equal to the grain temperature setpoint, and shut off if the grain temperature drops 1°F (0.56°C) below its

setpoint. See

Setting the 1-Speed Temperature Scheme in Continuous Flow, page 58

for details on how to

set up this control scheme.

42

PNEG-1851 Vision N2