Configuration – VEGA VEGACOM 557 Profibus FMS User Manual

Page 5

VEGACOM 557 Profibus FMS

5

Product description

The data set is transferred from this buffer

memory into a process image. The protocol

conversion software enquires the stored data

cyclically from the individual storage areas.

The data sets are checked and converted

into the PROFIBUS data format. After the

conversion, the data are transferred into

emission memory and are sent from there to

the PROFIBUS. The PROFIBUS transmits the

data to the PROFIBUS master, loading them

via a special connection component.

The data communication between VEGACOM

557 and PROFIBUS master must be initiated

by the master which can enquire the re-

quested information by special commands.

Configuration

The component is compatible with 19" tech-

nology with 5 TE width (1 TE = 5.08 mm) acc.

to DIN 41 494. It can be used

- in carrier BGT 596

- in VEGALOG 571 carrier

- in housing type 505

The electrical connection is made via a plug

connector acc. to DIN 41 612 on the rear of

the component. The connection to LOGBUS

is made via an additional 5-pole plug connec-

tion mounted to the DIN plug connector.

There is a 9-pole D-SUB plug in the front

plate. It is used for connection of a PC via

RS 232 C to VEGACOM 557.

The component consists of two boards:

- the basic board

- the additional board

The power supply unit, the PC RS 232C inter-

face as well as the DISBUS/LOGBUS inter-

face are located on the basic board.

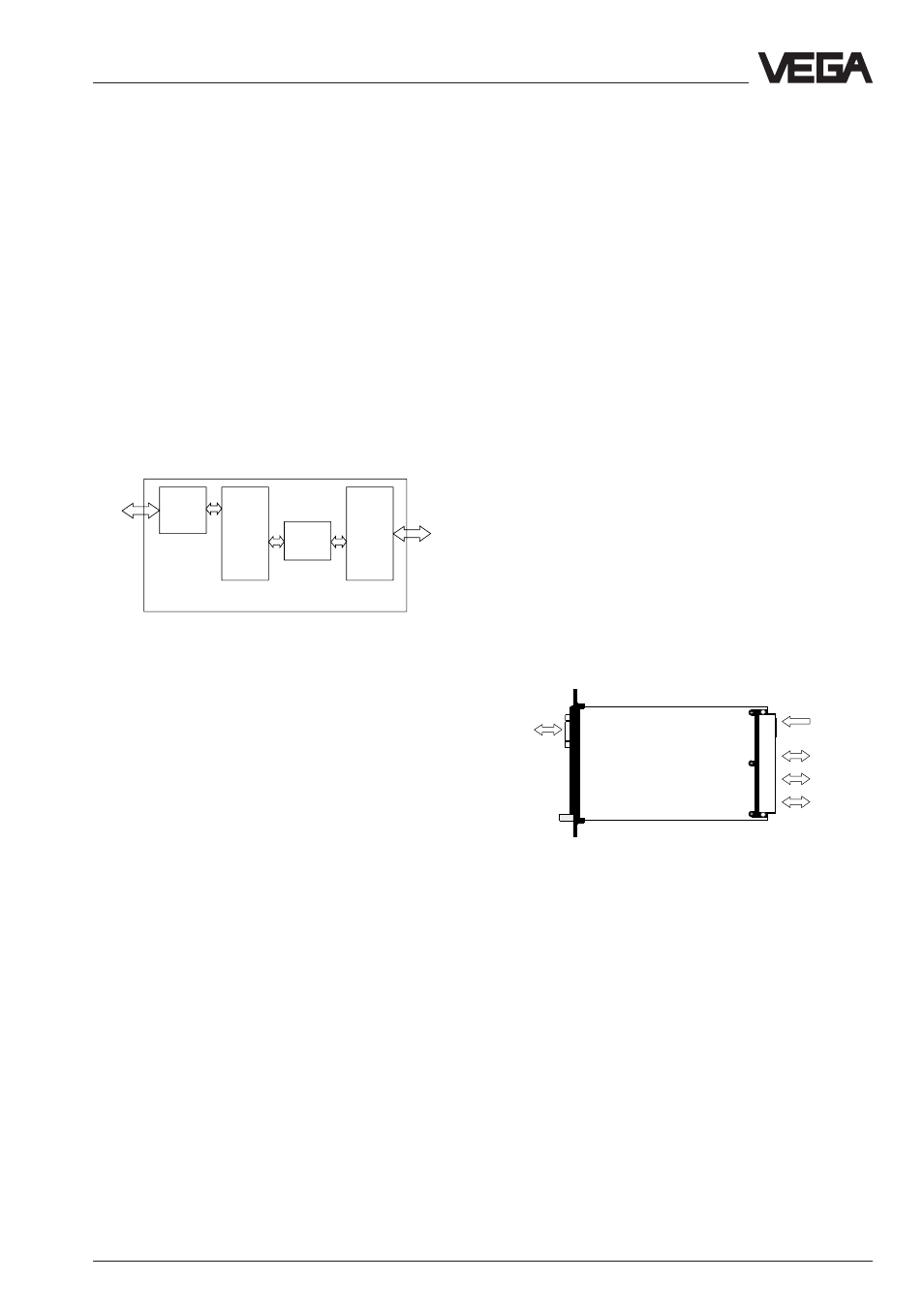

PC

interface

Connections of VEGACOM 557

PROFIBUS

LOGBUS

DISBUS

Supply

DISBUS

Buffer

memory

Process

image

LOGBUS

Emis-

sion

memory

PROFIBUS

Function of VEGACOM 557

Test

conver-

sion

By means of VEGACOM 557, as well as a PC

in conjunction with the adjustment software

VEGA Visual Operating (VVO), the con-

nected signal conditioning instruments can

be easily set up and configured. Further-

more, measured values and fault signals can

be shown graphically with the visualisation

software Visual VEGA (VV).

In a planned extension level, the PROFIBUS

master can also enquire, in addition to the

measurement data and status information,

the parameters of VEGAMET/VEGALOG,

receive them, and if necessary, modify and

return them. This strategy enables the com-

plete control of the behaviour of level and

process pressure measuring systems via

the PROFIBUS master.

The additional board is screwed to the basic

board and contains the microcontroller as

well as the PROFIBUS interface.