Starting, Figure 4, Terminals for mains supply and temperature alarm – M&C TechGroup ECP3000 Operator's manual User Manual

Page 14: 13 starting

14

Gas sampling and gas conditioning technology

3-1.1-ME

Coolers from serial nos.: 95.. also have a mains selector (S1) on the basic board for either 230V 50Hz

or 115V 60Hz operation on the basic circuit board (see circuit diagram in appendix).

Before commissioning, use a screwdriver to turn the selector to the correct position 230/115

depending on your main power input supply.

The status alarm contact for indicating and isolating the gas supply must be incorporated into the

equipment control system.

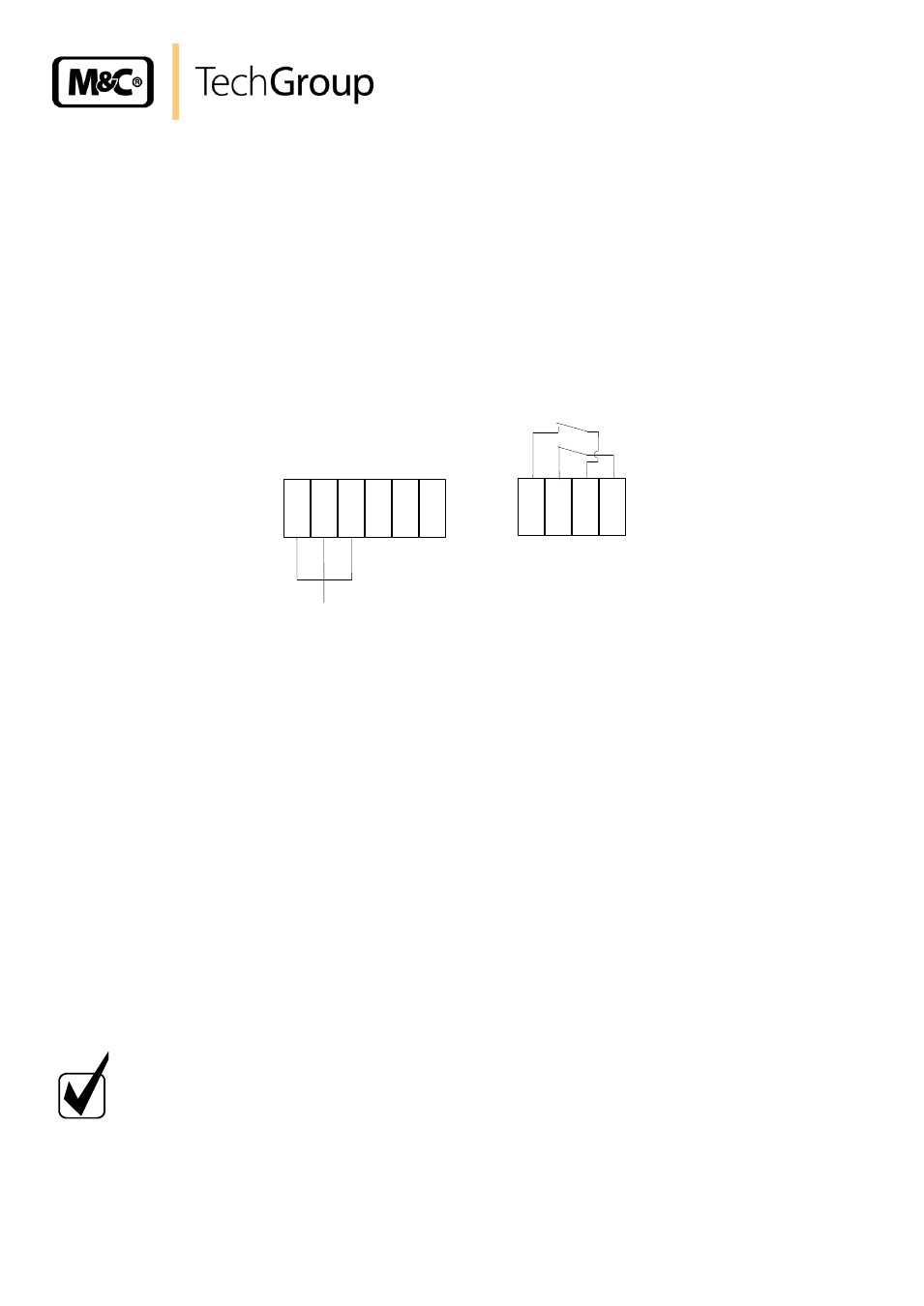

The volt free contact outputs of the status group alarm is located on the ECP .000 control board:

Temp. Alarm Terminal X2: 1 and 3 normal opened, 2 and 4 normal closed.

The two PG11 cable glands are located on the underside of the cooler enclosure. For further details

refer to the electrical circuits and terminal drawing and cover plate.

1

L

2

N

4

PE

3

PE

5

L

6

N

1

2

3

4

X1

X2

Netz/Power

230V/115V

50Hz/60Hz

ECP 1000 100VA

ECP 2000/3000 110VA

Alarm

250V AC

2A

500VA

ECP 1000/2000/3000

Sicherung F1 1,6 A

T

Fuse F2 1,6 A

T

Figure 4

Terminals for mains supply and temperature alarm

13

STARTING

Before using the equipment for the first time, check that the safety measures specific to the installation

and process are complied with!

The automatic control electronics of the ECP 1000/2000/3000 permit automatic start-up of the cooler.

The error diagnostics guarantee full monitoring and reporting of possible sources of error.

The following description is valid for start-up of the gas cooler for an ambient temperature > 8°C.

The following steps should be carried out before initial start-up:

Connect the cooler unit to the mains power supply;

Lead the status contacts for reporting of under- and over-temperature to the measuring station;

N O T E !

The status contacts must be connected to the external sample gas pump or

to a valve in the sample gas line to protect the entire analysis system by

immediately cutting off the gas supply in the event of error messages from

the cooler!