Description, Figure 2 – M&C TechGroup PSS-5_3 Operator's manual User Manual

Page 9

9

Gas sampling and gas conditioning technology

4-2.1.1-ME

9

DESCRIPTION

Cooler

ECP

>°C

ON

<°C

EIN

Meßgas

AUS

AUS

Kondensat

max. 1800VA

GL18

GL25

11

255

540

440

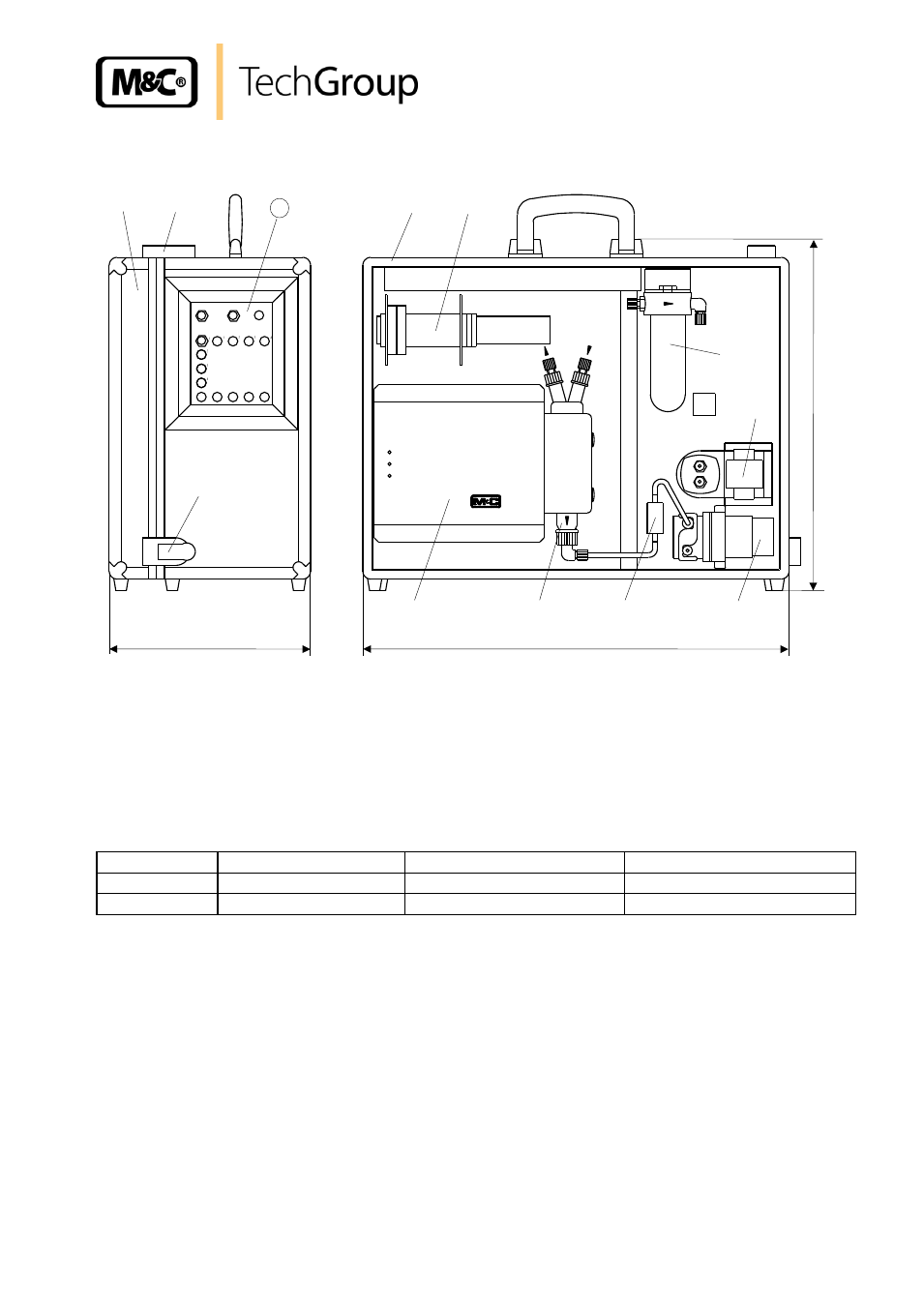

Figure 2

Design of the conditioning and sampling system PSS-5 and PSS-5/3

All the components of the gas conditioning system can be easily removed from the portable case 1 .

The door of the case 2 can be opened by moving the toggle-type fasteners 3 on the side and the top

to the left. The installation of a gas cooler 4 and an appropriate diaphragm gas pump 8 will be

carried out according to the maximum flow of gas extracted (see instruction manual for individual

components). The possible combinations are listed in the following table:

PSS-5...

Type of cooler

max. gas flow [Nl/h]

Sample gas pump

PSS-5

ECP1000

150

N 3 KPE

PSS-5/3

ECP3000

350

N 9 KPE

The minimum amount of flow is determined by the sample gas pump (see 15.). Premature damage

can be caused to the pump membrane if less than the minimal total amount of flow is extracted as a

result of excess pressure.

All gas coolers are equipped with a Borosilicate glass heat exchanger . Heat exchangers of PVDF

or stainless steel are also available.

The preliminary filter FP-2T (2 mm filter element fineness) installed in front of the gas measuring

pump 8 ensures that the correct amount of solid matter is precipitated. The sample gas pump is

turned off and on automatically by means of an excess temperature contact on the cooler (+8°C).

The resulting condensation is continually lead off by means of the SR25.1 9 peristaltic pump (s.

individual component instructions).

A preliminary filter, PF2 has been fitted in the condensation hose in between the heat exchanger

and peristaltic pump. This prevents particles in the condensate entering the pump.