Supply connections, Hose connections, N o t e – M&C TechGroup PSS-5_3 Operator's manual User Manual

Page 12

12

Gas sampling and gas conditioning technology

4-2.1.1-ME

12

SUPPLY CONNECTIONS

12.1

HOSE CONNECTIONS

N O T E !

Do not mix up the hose connections: they are clearly marked.

After all the hoses have been connected, the tightness of such

leads should be checked.

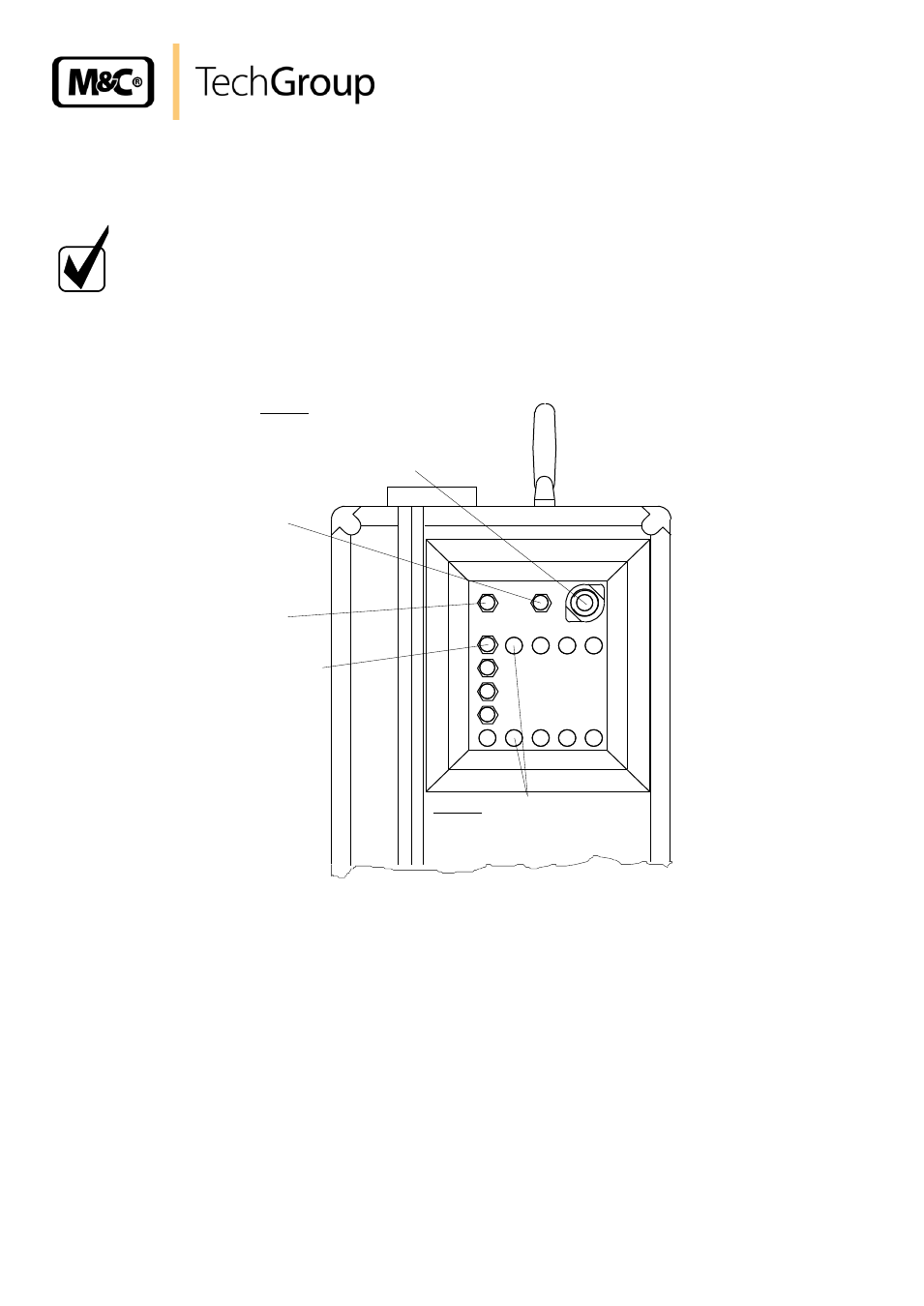

Figure 3 shows the possible medium connections. These are located in the right-hand side of the

gas conditioning case at the rear in a specially immersed assembly frame.

Option:

Mounting of max. 4 FM40

flowmeters possible

EIN

Meßgas

AUS

AUS

Kondensat

1

1

2

3

4

2

3

4

Condensate

Outlet

Sample gas

Outlet

(Option: max. 4)

Sample gas

Inlet

Option:

Electrical connection

for heated sample line

max. 6A, (230V/50Hz or 115V/60Hz)

All hose connections are equipped with 4/6mm sealing ring threaded hose couplings made of

polypropylene (PP) for gas input temperatures of up to a maximum of 80°C (see 8.). If heated

sample lines are used, whereby the gas input temperatures are increased up to a maximum of

180°C, additional bulkhead unions made of stainless steel are recommended.

Connection hoses with dimensions DN 4/6mm are utilised for all models.

The sample gas hoses, and condensation hoses, are to be assembled as follows:

Remove the union nut from the sealing ring couplings by turning it anti-clockwise. The nut should

be removed from the thread with great care so as to ensure that the loose sealing ring in the nut

is not lost.

Place the union nut over the connecting hose.