Trouble shooting – M&C TechGroup MP12 Operator's manual User Manual

Page 16

16

Gas sampling and gas conditioning technology

6-1.1.10-ME

15

TROUBLE SHOOTING

Before working on the pump, isolate the power supply securely, then check that the lines are not live.

The following tips for fault-finding are best employed in the sequence shown.

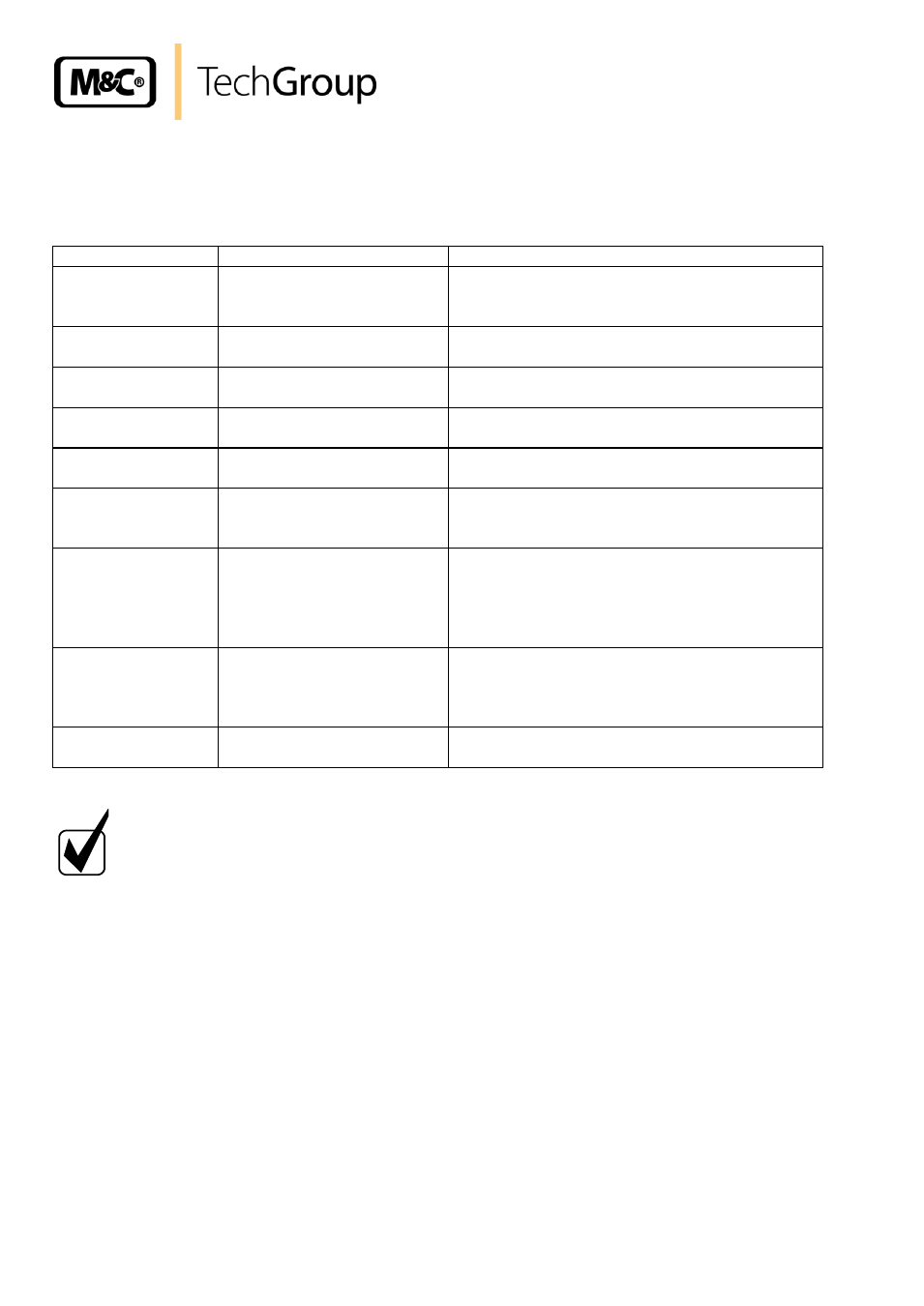

Problem/indication

Possible cause

Action/Check

Pump produces no

flow

No main supply.

Check power supply. Check plug for correct fit.

Connections or lines are

blocked.

Remove blockade.

An external valve is closed

or a filter is blocked.

Open valve or clean blocked/dirty filter.

Liquid (condensate) has

collected in the pump head.

Let the pump for a few minutes pumping air.

Flow, pressure or

vacuum too low

Diaphragm or valves are

worn out.

Change diaphragm or/and valves.

Compare the actual per-

formance with the figures in

the technical data.

The pump is not designed for this condition.

There is pressure on the

pressure side and at the

same time vacuum or a

pressure above atmospheric

on the suction side.

The pump is not designed for this condition.

The cross-section of pneu-

matic lines or connected

components is too small, or

they are restricted.

To measure the performance, disconnect the

pump from the system (smaller diameter tubing

or a valve can significantly affect performance).

A leak at a connector, in a

line or in the pump head.

Insulate the leak, tighten the screws, clean or

exchange dirty parts.

N O T E !

If the pump does not operate properly and you can not find any of the

above mentioned faults, send it back to M&C.

If the pump is sent for repair, please provide information about sample

(aggressive or corrosive components etc.)

If the sample is dangerous or highly aggressive the pump must be cleaned

before dispatch.