Introduction, Application, Technical data – M&C TechGroup VC-2-SL Operator's manual User Manual

Page 7

7

Gas sampling and gas conditioning technology

3-0.1-ME

6

INTRODUCTION

The VC-... pre-cooling units produced by M&C

incorporates the “Jet-Stream’’ design of heat

exchanger. This design induces condensate formation and guarantees optimum dew point reduction to

ambient temperature.

7

APPLICATION

The M&C pre-cooling units VC-... are used in gas analysis to lower the dew point of humid gas, for

example:

• to relieve downstream main cooling system

• if process-bound water or steam irruption can become forward,

• if non-heated sample lines without adequate slope are mounted,

• for gas analysis system with electrochemical sensors.

8

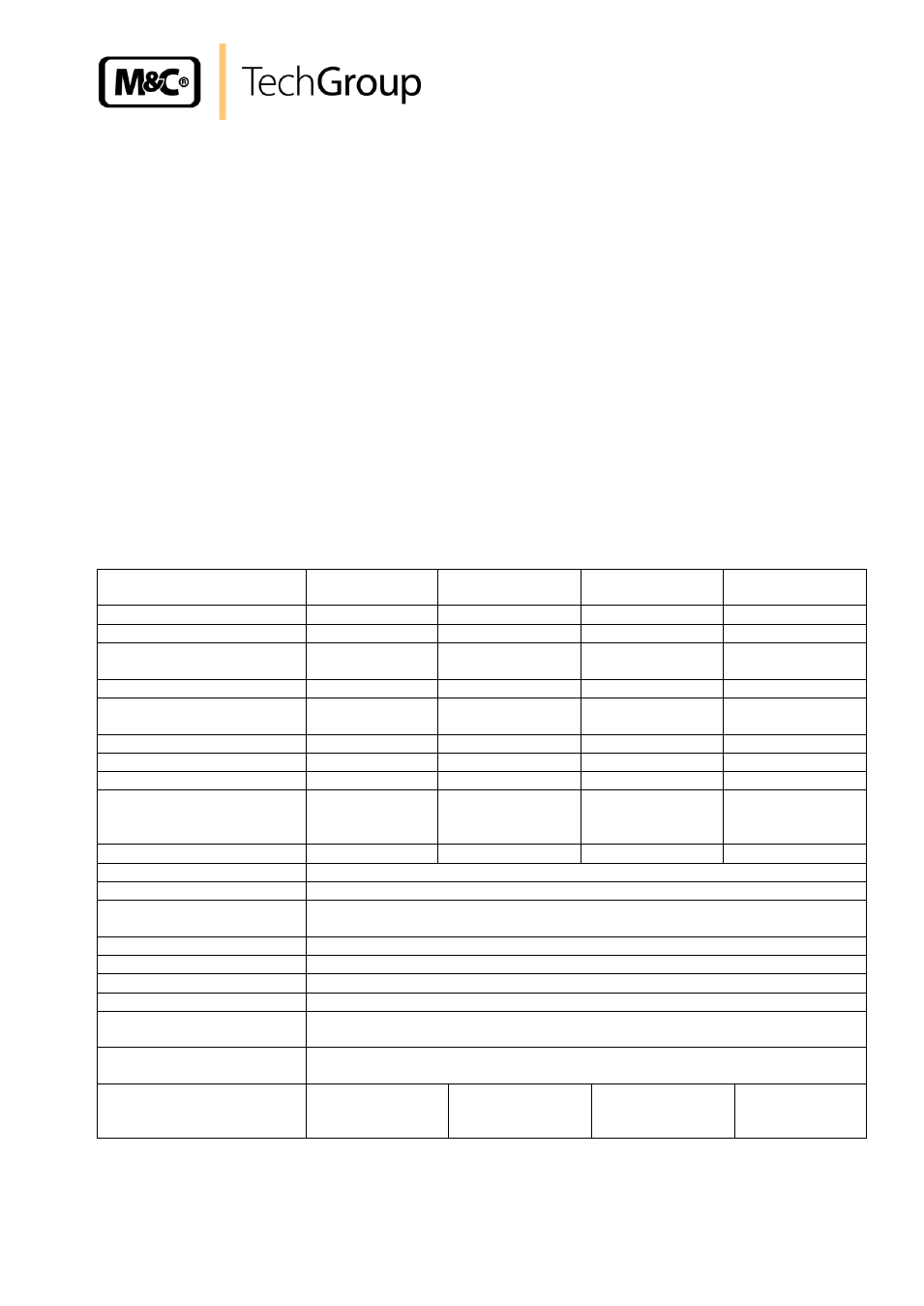

TECHNICAL DATA

Pre-cooling unit version

VC-..

VC-1

VC-1-SL

VC-2-L

VC-2-SL

Part No. 230V 50-60Hz

03K1000

03K3000

03K4000

03K5000

Part No. 115V 50-60Hz

03K1000

03K3000a

03K4000a

03K5000a

Jet-Stream heat exchanger

out of Duran glass EC-G

1x

1x

2x

2x

Forced ventilation

no

yes

yes

yes

Autom. condensate

removal with SR25..

1x

2x

Sample gas connection

2x GL18-6

2x GL18-6

4x GL18-6

4x GL18-6

Condensate connection

1x GL25-12

1x DN4/6

2x GL25-12

2x DN4/6

Power consumption

25VA

20VA

30VA

Gas flow rate

recommended, (other flow

rates possible)

1x 250 Nl/h

1x 250 Nl/h

2x 250 Nl/h

2x 250 Nl/h

Weight approximately

ca. 3,5 kg

ca. 7,5 kg

ca. 9 kg

ca. 11 kg

Sample gas pressure

max. 3 bar g

ΔP per heat exchanger

4 mbar at 300 Nl/hr

Stagnant space per heat

exchanger

70 ml

Sample inlet temperature

max. 180 °C

Ambient temperature

+2 °C to +45 °C

Storage temperature

0 °C to +55 °C

Electrical connection

Terminals max. 2,5 mm

2

, PG11 cable gland

Electrical standard / Case

protection

EN 61010 / IP22-EN60529

Method of mounting /

Ready for working

mounting / immediately

Material of sample

contacting parts

Duran glass®,

PTFE

Duran glass®,

PTFE, PVDF,

Novoprene

Duran glass®,

PTFE

Duran glass®,

PTFE, PVDF,

Novoprene