Mechanical zero point adjustment, Figure 8, Schematic view of the transmitter unit – M&C TechGroup PMA 50 EEX Operator's manual User Manual

Page 33

33

Gas sampling and gas conditioning technology

9-3.15-ME

23.2

MECHANICAL ZERO POINT ADJUSTMENT

The mechanical zero point adjustment has to be done as described in the following.

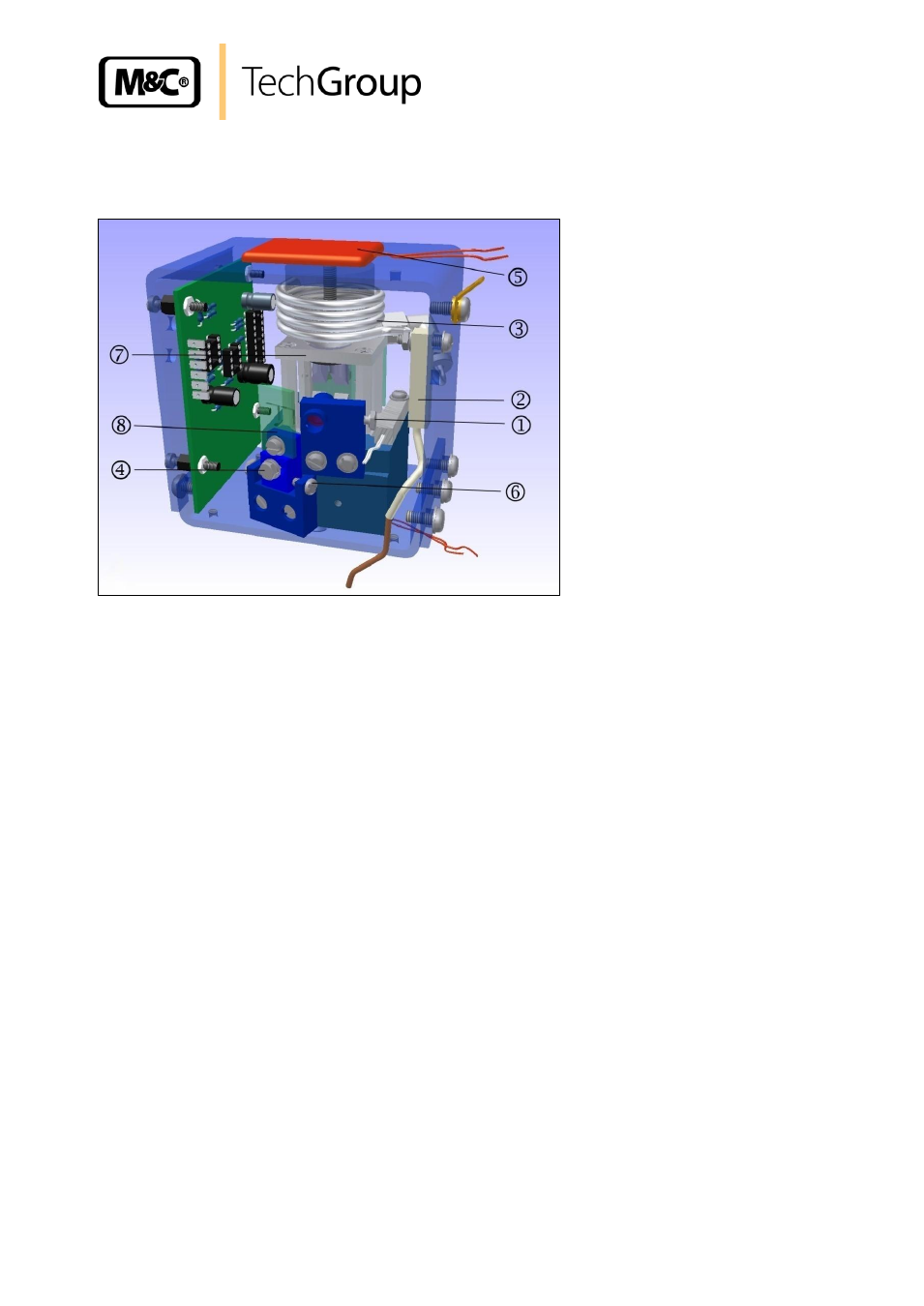

1 IR LED 5 Heater element

2 Temperature cut out (72°C) 6 Adjustment screw photocell

3 Sample gas heating coil 7 Measuring cell

4 Fastening screw photocell 8 Photocell

Figure 8

Schematic view of the transmitter unit

Before switching on the analyser, set the range selector to 30%. Control the zero point of the analogue

display and adjust it if necessary to 0% via the adjustment screw below the digital display;

Switch on the analyser via the external switch. Normally, the analogue display will indicate a value of

21% oxygen because the cell is filled with ambient air;

The warming up is indicated by the permanently beaming LED in the front plate of the analyser; after

approx. 30 minutes, the flashing display signalizes that the required operating temperature has been

reached;

Set the potentiometer for zero point and span value in the mid position; you can do this by turning the

potentiometer with a screw driver fully to the left and then turn it five turns back to the right;

Charge the analyser with a zero gas volume flow of approx. 40 l/h;

With a precise adjustment of the zero point, the analogue display should indicate 0.0 Vol.% oxygen;

If this does not happen, please execute the following steps:

Open the housing of the analyser (see 23.1);

Remove carefully the isolating cap of the transmitter unit; now, all screws of the photocell fixing are

visible (see figure 8);

Set the range switch to 3%;

Turn the adjustment screw 6 (see figure 8) of the photocell as long clockwise or anticlockwise as on

the display appears a value of nearly 0,0 Vol.% oxygen;

After the mechanical zero point adjustment, the fixing screw of the photocell fixing 4 must be screwed

down again;

Now, the zero point adjustment has been done;

Place carefully the isolating cap on the analyser and close it according to 23.1.