Bosch GCM 12 JL Professional User Manual

Page 34

34 | English

1 619 929 L91 | (6.8.12)

Bosch Power Tools

Minimal workpiece sizes

(= all workpieces that can be clamped left or right from the

saw blade with the supplied material clamp 40):

128 x 40 mm (length x width)

Cutting depth, max.

Workpiece against fence (0°/0°): 75 mm

Workpiece against distance-stop

(moved toward the front) (0°/0°): 100 mm

Cutting Off

– Firmly clamp the workpiece as appropriate for its dimen-

sions.

– Adjust the requested mitre and/or bevel angle.

– Switch on the machine.

– Press lever 22 and slowly guide the tool arm downward by

handle 4.

– Saw through the workpiece applying uniform feed.

– Switch off the machine and wait until the saw blade has

come to a complete stop.

– Guide the tool arm slowly upward.

Sawing Workpieces of the Same Length (see figure P)

The material stop 27 can be used for easily sawing workpiec-

es to the same length.

The material stop can be mounted on either side of the saw ta-

ble extension 15.

– Loosen lock screw 28 and swing the material stop 27 over

clamping screw 53.

– Retighten lock screw 28.

– Adjust the saw table extension 15 to the desired length

(see “Extending the Saw Table”, page 32).

Special Workpieces

When sawing curved or round workpieces, these must be es-

pecially secured against slipping. At the cutting line, no gap

may exist between workpiece, fence and saw table.

Provide for special fixtures, if required.

Replacing Insert Plates (see figure Q)

The red insert plates 39 can become worn after prolonged

use of the machine.

Replace defective insert plates.

– Bring the power tool into the working position.

– Unscrew screws 54 with the provided Allen key (4 mm) 17

and remove the old insert plates.

– Insert the new right-hand insert plate.

– Screw the insert plate with the screws 54 as far as possible

to the right, so that the saw blade does not come in contact

with the insert plate throughout the complete possible rip-

ping length.

– Repeat the work steps in the same manner for the left-hand

insert plate.

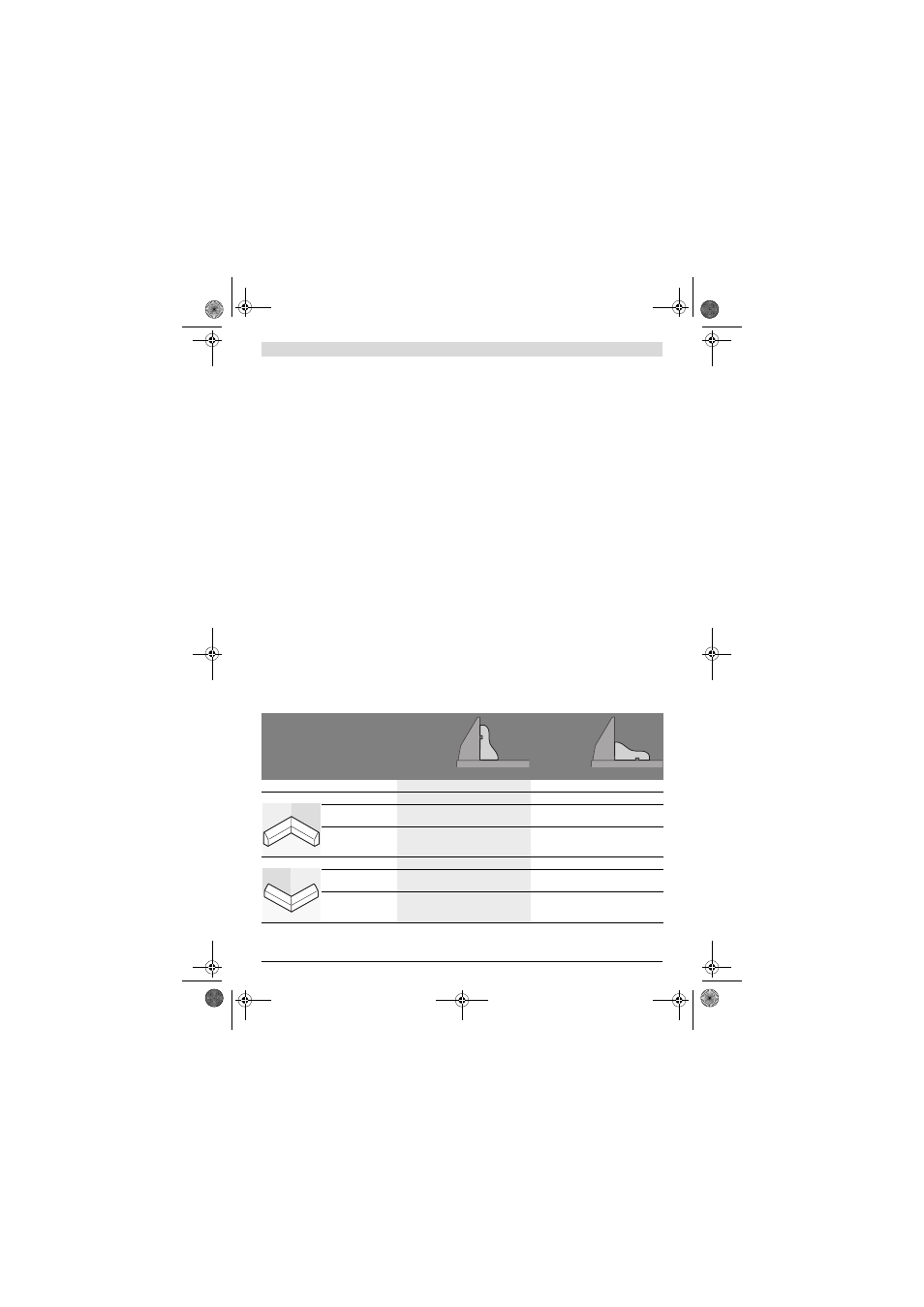

Sawing Profile Strips/Mouldings (Floor and Ceiling Strips)

Profile strips/mouldings can be sawn in two different ways:

– Placed against the fence

– Lying flat on the saw table.

Always make trial cuts with the mitre angle setting first on

scrap wood.

Floor Strips/Mouldings

The following table contains instructions for sawing floor strips/mouldings.

Settings

Placed

against the

fence

Lying flat on

the saw table

Bevel angle

0°

45°

Floor strip/moulding

Left side

Right side

Left side

Right side

Inner corner

Horizontal mitre angle

45° left

45° right

0°

0°

Positioning of work-

piece

Bottom edge on

saw table

Bottom edge on

saw table

Upper edge against

the fence

Bottom edge

against the fence

The finished work-

piece is located...

... to the left of the

cut

... to the right of the

cut

... to the left of the

cut

... to the left of the

cut

Outer corner

Horizontal mitre angle

45° right

45° left

0°

0°

Positioning of work-

piece

Bottom edge on

saw table

Bottom edge on

saw table

Bottom edge

against the fence

Upper edge against

the fence

The finished work-

piece is located...

... to the left of the

cut

... to the right of the

cut

... to the right of the

cut

... to the right of the

cut

OBJ_BUCH-1600-002.book Page 34 Monday, August 6, 2012 3:36 PM