Service & maint. — annual start-up, Start-up, Check/test – Weil-McLain GOLD CGS 550-110-260/02002 User Manual

Page 38: Gold cgs gas-fired water boiler, Continued

Part number 550-110-260/0200

38

GOLD

CGs

Gas-Fired Water Boiler

Service & maint. —

annual start-up

continued

10b

❏

Start-up . . . . . . . . .

1. Start the boiler, following the instructions in

manual section

7

.

2. Verify

cold fill pressure

is correct and that fill

system is working properly.

3. Verify

antifreeze level

(if used) is at the right

concentration and that inhibitor level is correct.

4.

Check gas piping

, per manual Sections

5

and

7

,

verifying no indications of leakage and all piping

and connections are in good condition.

5. Read the

Lighting instructions

(

Figure 21

of this

manual or on boiler label) applying to the boiler.

6. Start the boiler following the

Lighting instructions

and manual section

7

.

❏

Check/test . . . . . . .

Gas piping

1. Sniff near floor and around boiler area for any

indication of a

gas leak

.

2.

Test gas piping using bubble test,

per section

5

of this manual, if there is any indication of a leak.

Cold fill and operating pressures

1. While the system is cold, note the

pressure reading

on the boiler pressure/temperature gauge. Verify that

cold fill pressure is correct.

2.

Watch the pressure

as the boiler and system heat

up to ensure pressure rise is normal. Too high a

rise would indicate a waterlogged or undersized

expansion tank.

Air vents and air elimination

1. Inspect automatic air vents (if used). Also inspect

air separators to ensure they are operational.

2. The cap must be unscrewed one turn to allow air

to escape.

3. See

Figure 22

. If the air vent is leaking, remove cap

A

and briefly push valve

B

and then release to clean

the valve seat.

4. Replace cap

A

by twisting all the way onto valve

B

and then unscrewing one turn.

Limit controls and cutoffs

1. Inspect and test the boiler limit control. Verify

operation by turning control set point below boiler

temperature. Boiler should cycle off. Return dial to

original setting.

2. Inspect and test additional limit controls or low

water cutoffs installed on system.

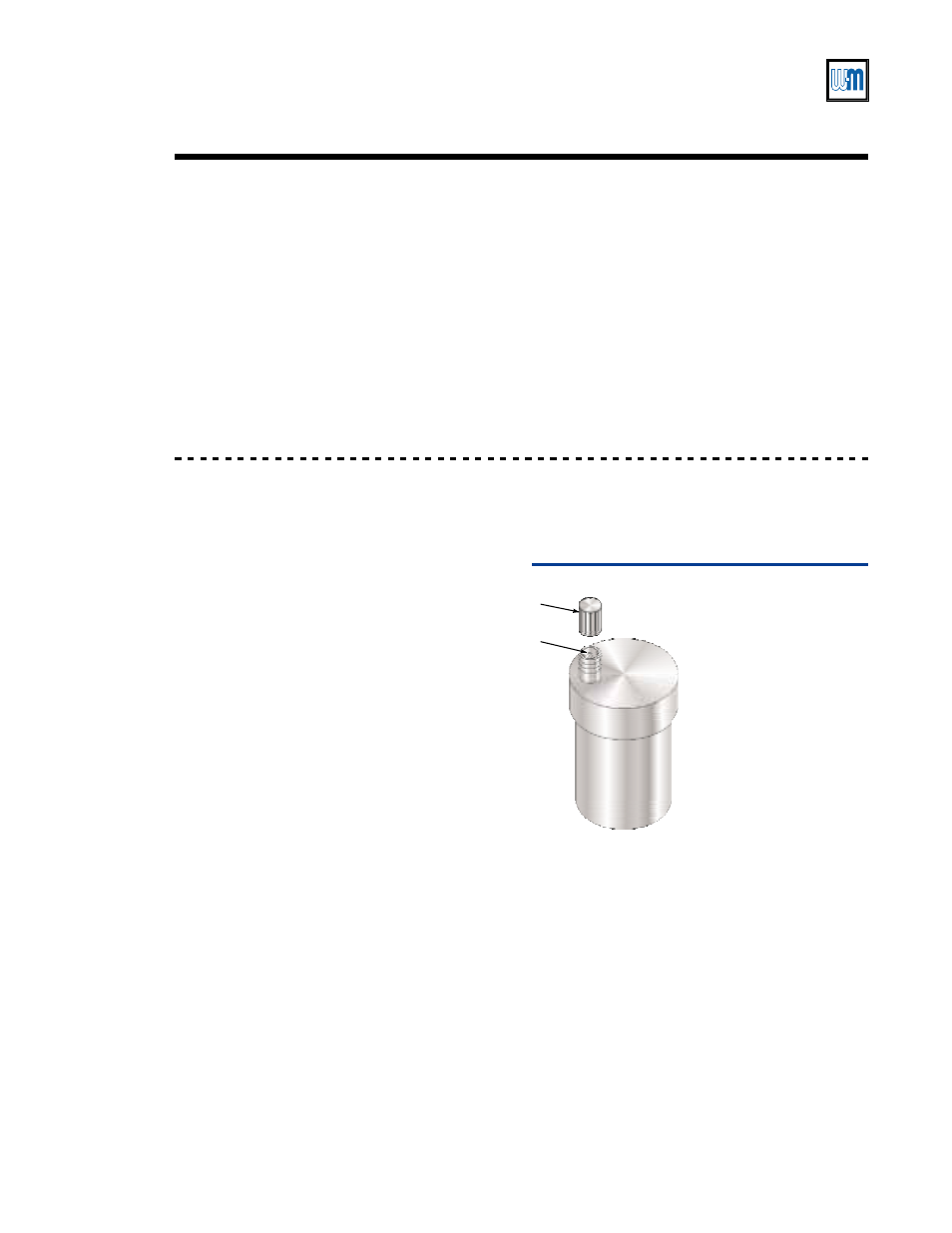

Figure 22

Automatic air vent, typical

26031

A

B

Expansion tank

1. Expansion tanks provide space for water to move

in an out as the heating system water expands due

to temperature increase or contracts as the water

cools. Tanks may be open, closed or diaphragm or

bladder type. See section

3

of this manual for

suggested best location of expansion tanks and air

eliminators.

Open-type

— located above highest radiator or

baseboard unit, usually in the attic or closet. Has a

gauge glass and overflow pipe to a drain.

Closed-type

— welded gas tight and located above

boiler. Tank is partially filled with water, leaving an

air cushion for expansion.

•

Make sure this type of tank is fitted with a

tank

fitting

, such as the B & G Tank-Trol or Taco

Taco-Trol. This fitting reduces gravity