Typical piping — multiple-zone installations, Boiler manual – Weil-McLain GOLD CGS 550-110-260/02002 User Manual

Page 17

Part number 550-110-260/0200

17

Boiler Manual

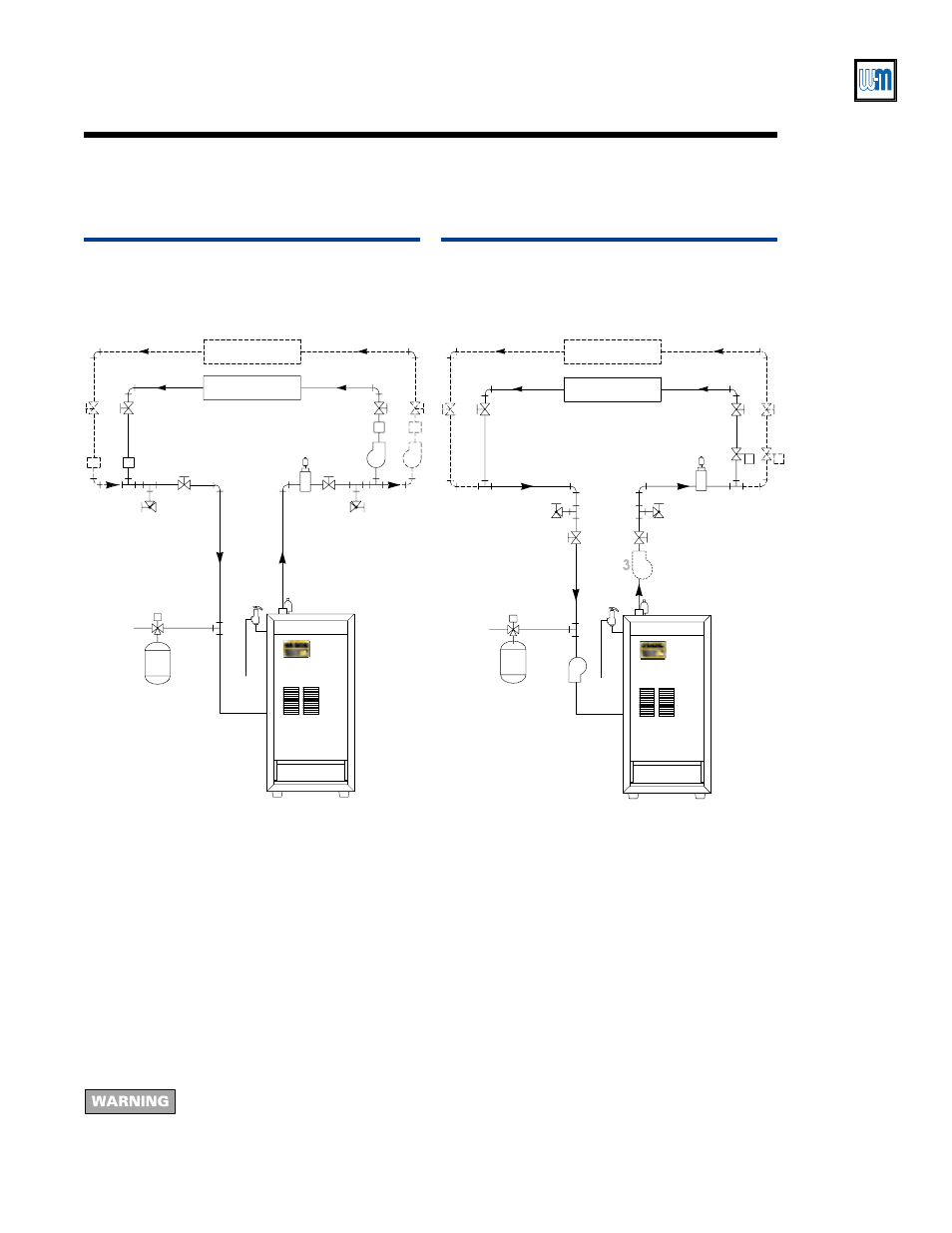

typical piping — multiple-zone installations

Figure 6

Zoning with circulators

— return water 130 °F or higher.

Figure 7

Zoning with zone valves

— return water 130 °F or higher.

1

Boiler isolation (balancing) valves

2

Flow/check valve

3

System or zone circulator

5

Zone valve

6

Drain valve

9

Relief valve

10

Automatic air vent (with diaphragm-type

expansion tank), or connect to tank fitting (closed-

type expansion tank).

DO NOT

use an automatic

air vent when using closed-type expansion tank. It

would allow air to leave the system, causing

waterlogging of the expansion tank.

11

Fill valve

12

Diaphragm-type or bladder-type expansion tank,

if used (For closed-type expansion tank, pipe from

top of air separator to tank fitting as in

Figure 5

.)

13

Air separator and automatic vent, if used (Note that

the fill valve must always be connected to the

expansion tank, regardless of location of expansion

tank circulator or air separator.

For systems with possible low return-water temperature (such as converted gravity systems,

radiant heating systems and heat pump systems), refer to the special piping suggestions of

Figures 8 - 12

, as applies. Failure to prevent sustained low return water temperature to the

boiler could cause corrosion of the boiler sections, resulting in severe personal injury, death

or substantial property damage.

26012

10

Cold

water

fill

11

12

9

ZONE 2

ZONE 1

1

1

1

2

2

3

1

6

6

13

26013

10

Cold

water

fill

11

12

9

ZONE 2

ZONE 1

1

6

1

1

6

1

5

13

Alternate

circulator

location