Cool output curve, Control methods, Output configuration – Watlow Electric Integrated Controller User Manual Rev C EZ-ZONE PM User Manual

Page 61: Auto (closed loop) and manual (open loop) control

Wa t l o w E Z - Z O N E

®

P M I n t e g r a t e d C o n t r o l l e r

•

5 9

•

C h a p t e r 9 F e a t u r e s

Retransmit Source

Output Scale

Range High

Range Low

Scale High

Scale Low

Set the range of the process output with Scale

Low

[`S;Lo] and Scale High [`S;hi]. Scale the re-

transmit source to the process output with Range

Low

[`r;Lo] and Range High [`r;hi].

When the retransmit source is at the Range Low

value, the retransmit output will be at its Scale Low

value. When the retransmit source is at the Range

High value, the retransmit output will be at its Scale

High value.

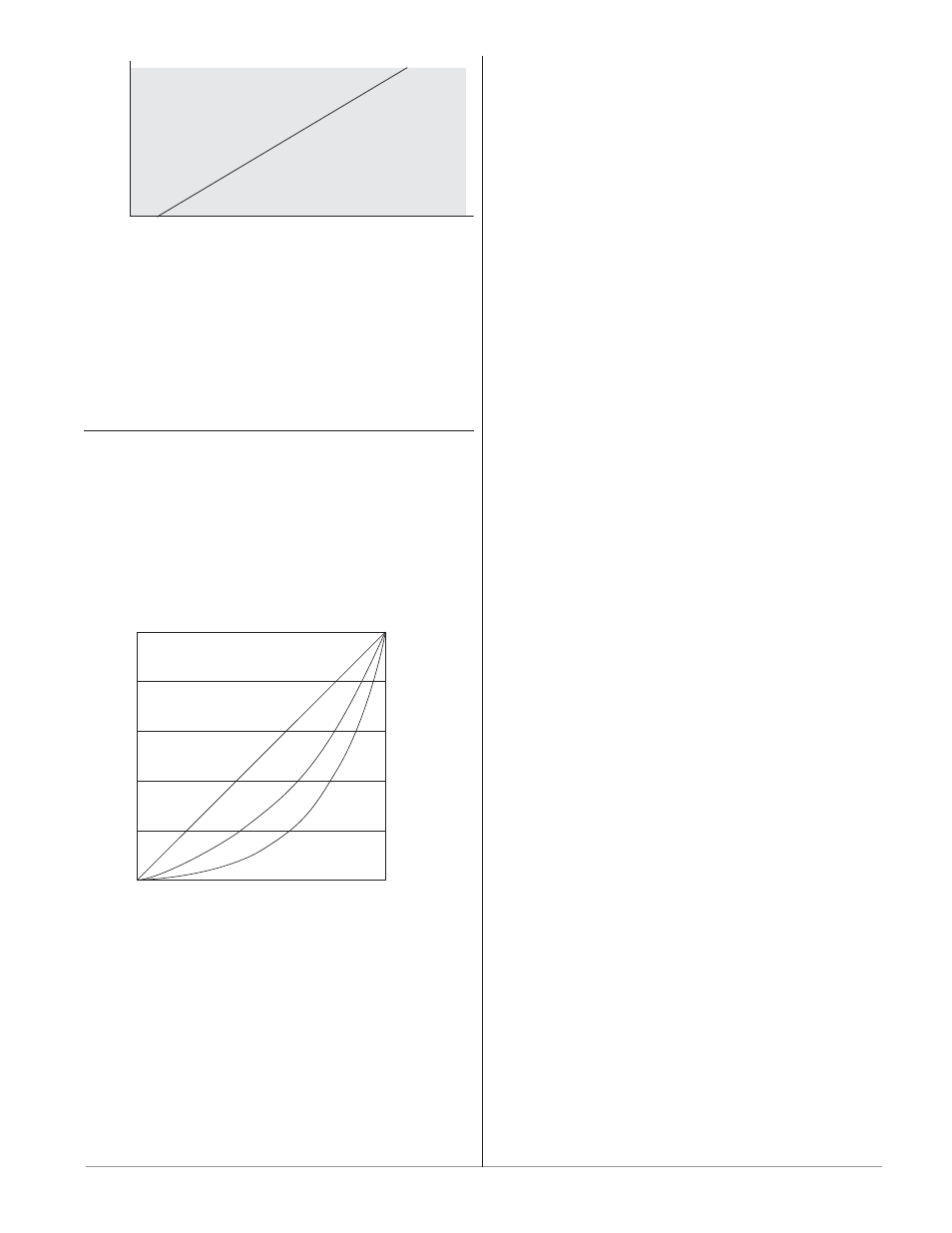

Cool Output Curve

A nonlinear output curve may improve performance

when the response of the output device is nonlinear.

If a cool output uses one of the nonlinear curves a

PID calculation yields a lower actual output level

than a linear output would provide.

These output curves are used in plastics extruder

applications: curve 1 for oil-cooled extruders and

curve 2 for water-cooled extruders.

Actual Output Power

0

20

40

60

80

100

PID Calculation

Linear

Curve 1

Curve 2

Select a nonlinear cool output curve with Cool

Output Curve

[`C;Cr] (Setup Menu, Loop Menu).

Control Methods

Output Configuration

Each controller output can be configured as a heat

output, a cool output, an alarm output or deactivat-

ed. No dependency limitations have been placed on

the available combinations. The outputs can be con-

figured in any combination. For instance, all three

could be set to cool.

Heat and cool outputs use the set point and Oper-

ations parameters to determine the output value. All

heat and cool outputs use the same set point value.

Heat and cool each have their own set of control pa-

rameters. All heat outputs use the same set of heat

control parameters and all cool outputs use the same

set of cool output parameters.

Each alarm output has its own set of configura-

tion parameters and set points, allowing independent

operation.

Auto (closed loop) and Manual (open loop) Control

The controller has two basic modes of operation, auto

mode and manual mode. Auto mode allows the con-

troller to decide whether to perform closed-loop con-

trol or to follow the settings of Input Error Failure

[FAiL] (Setup Page, Loop Menu). The manual mode

only allows open-loop control. The EZ-ZONE

®

PM

controller is normally used in the auto mode. The

manual mode is usually only used for specialty appli-

cations or for troubleshooting.

Manual mode is open-loop control that allows the

user to directly set the power level to the controller’s

output load. No adjustments of the output power level

occur based on temperature or set point in this mode.

In auto mode, the controller monitors the input to

determine if closed-loop control is possible. The con-

troller checks to make certain a functioning sensor is

providing a valid input signal. If a valid input signal

is present, the controller will perform closed-loop con-

trol. Closed-loop control uses a process sensor to de-

termine the difference between the process value and

the set point. Then the controller applies power to a

control output load to reduce that difference.

If a valid input signal is not present, the control-

ler will indicate an input error message in the upper

display and

[Attn] in the lower display and respond

to the failure according to the setting of Input Error

Failure

[FAiL]. You can configure the controller to

perform a “bumpless” transfer

[bPLS], switch power

to output a preset fixed level

[MAn], or turn the out-

put power off.

Bumpless transfer will allow the controller to

transfer to the manual mode using the last power

value calculated in the auto mode if the process had

stabilized at a ±5 percent output power level for the

time interval of Time Integral (Operations Page,

Loop) prior to sensor failure, and that power level is

less than 75 percent.