Siemens Simotion A4027118-A0414 User Manual

Page 12

Section A: Prerequisites and objectives

Basic information

Flying Saw with SIMOTION

A4027118-A0414

V 1.4

Release 06/06/08

12/107

C

opyr

ight

©

Si

em

ens

AG 2

0

08

Al

l r

ights r

e

s

e

rv

ed

M

anual_

S

IM

OTION Fl

ying Saw

_

V1

.4.

d

oc

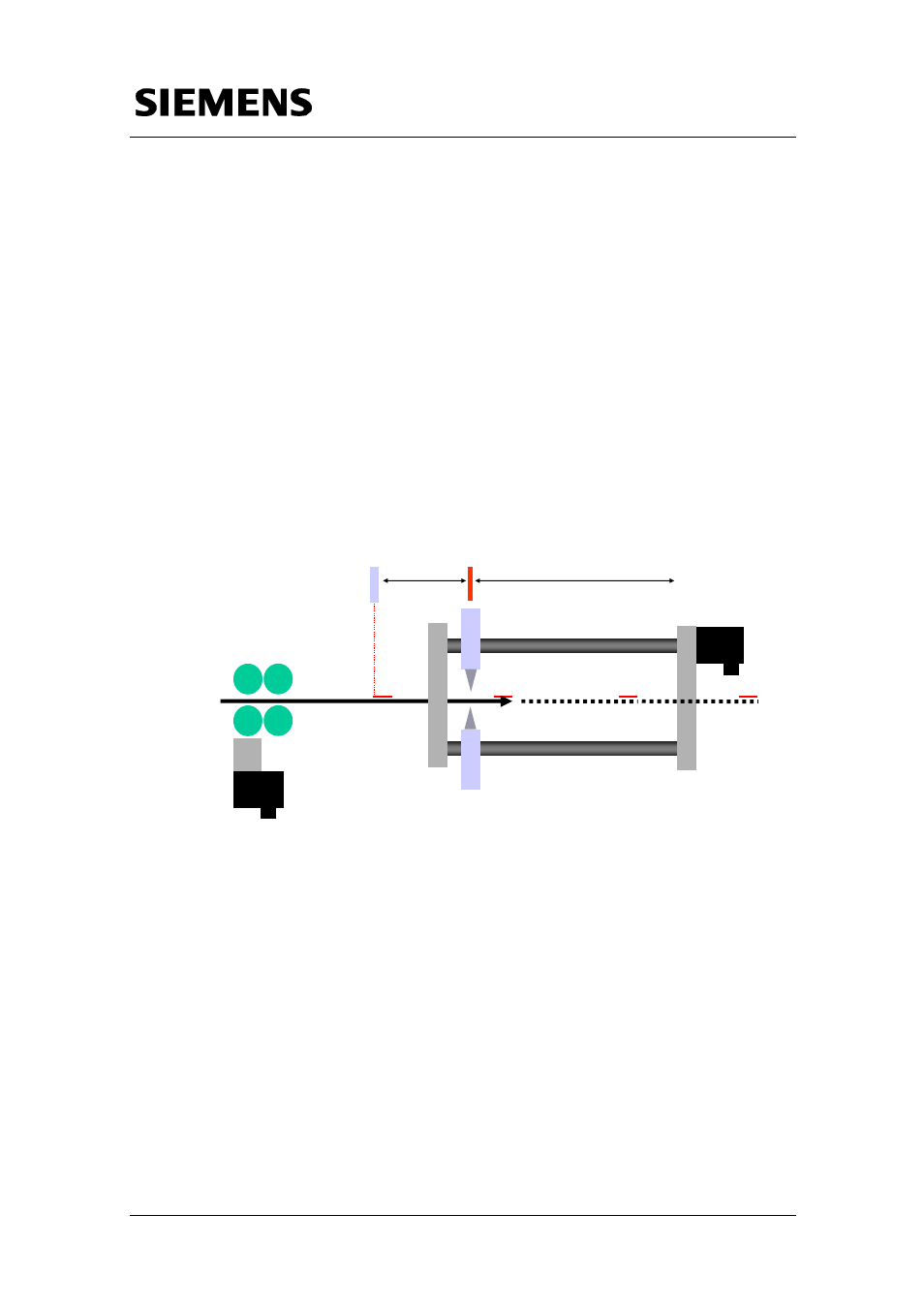

Principle design of a "flying saw"

The material is fed-in as an endless web (e.g. plastic, sheet steel or fiber

board) using a conveyor belt that runs with a constant velocity.

The position of the cut on the material web is either sensed using a print

mark using a sensor or is specified by the control after a cut length has

been passed that can be adjusted. The synchronous position is

simultaneously defined. From this point onwards, the shears slide of the

flying saw synchronously follows the material at the position to be cut and

the cut can be started. After the cut has been completed, the shears slide is

returned to its starting position where it waits for the next cut position.

Fig. 1-1: Principle of operation of the “flying saw”

Drive of flying saw

Web drive

or

measuring system

Sensor

Starting position

1.2.2

Solution using the standard “flying saw” application

The standard “flying saw” application discussed here can be used to

implement such applications, and to develop a functioning "flying saw" as

quickly as possible.

The standard application already includes, as core function, a pre-

configured motion control of the flying saw axis. This can be adapted to the

particular application using the appropriate parameters. The core function is

responsible for completely controlling the flying saw axis.