Hydraulic requirements – Hawk Industries Hawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 to 120 User Manual

Page 11

1. Pressure compensated pump set to

pressure compensate at 2500 psi.

2. Minimum volume of 20 gpm. 35 gpm for

top performance.

3. 1" minimum Pressure line. 1 1/4"

Pressure line if the power unit is located

more than 100' apart from the

HawkJaw. The hose working pressure

must be 3000 psi or greater.

4. 1 1/4" minimum Tank line. 500 psi

minimum hose working pressure.

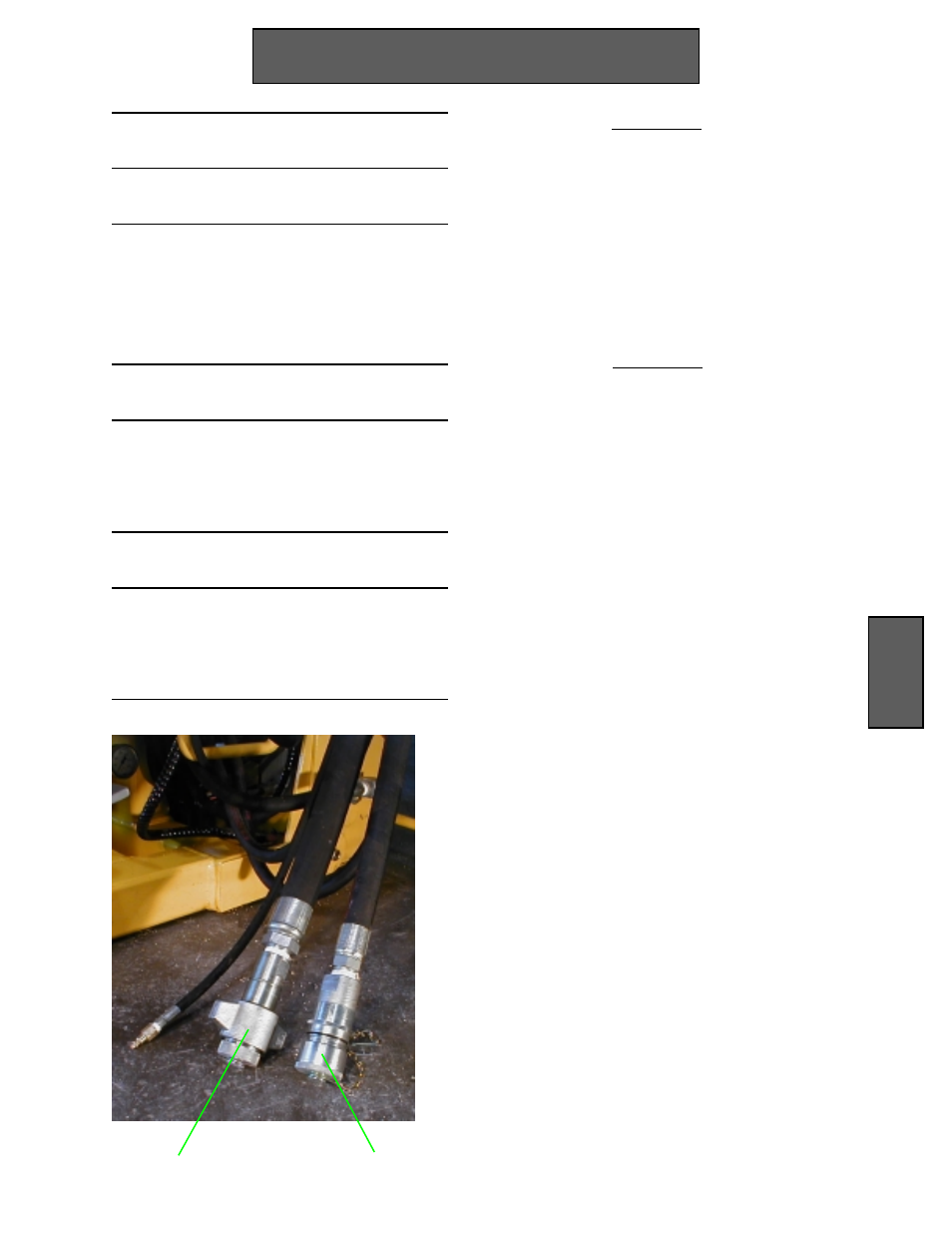

5. Hawk approved quick disconnects

[Male: Part # 061-H52 (MQD). Female:

Part # 061-H53 (FQD)]. Initial quick

disconnects supplied with the HawkJaw.

6. Hydraulic power unit located in a clean,

dry, ventilated area.

7. Enough slack in the lines for the

HawkJaw to move from its rest position

to the drill pipe connection to the

mousehole connection.

Hydraulic Requirements

Installation

11

Installation

MQD

Pressure

FQD

Tank

WARNING

The HawkJaw is a closed center system which

must have a pressure compensated volume con-

trolled power unit. If the only available hydraulic

power unit is constant volume, then the optional

hydraulic converter kit (Part # 061-J80) is re-

quired. Running the HawkJaw with a constant

volume hydraulic power unit may result in bodily

injury and will cause damage to the HawkJaw

and to the hydraulic power unit.

WARNING

The HawkJaw must receive clean hydraulic fluid.

Running the HawkJaw without a Hawk approved

filter (Part # 061-H25) and installed filter element

(Part # 061-H25A) voids the warranty and severely

shortens component life.