Troubleshooting – ITT S-DRIVE IM213 User Manual

Page 21

21

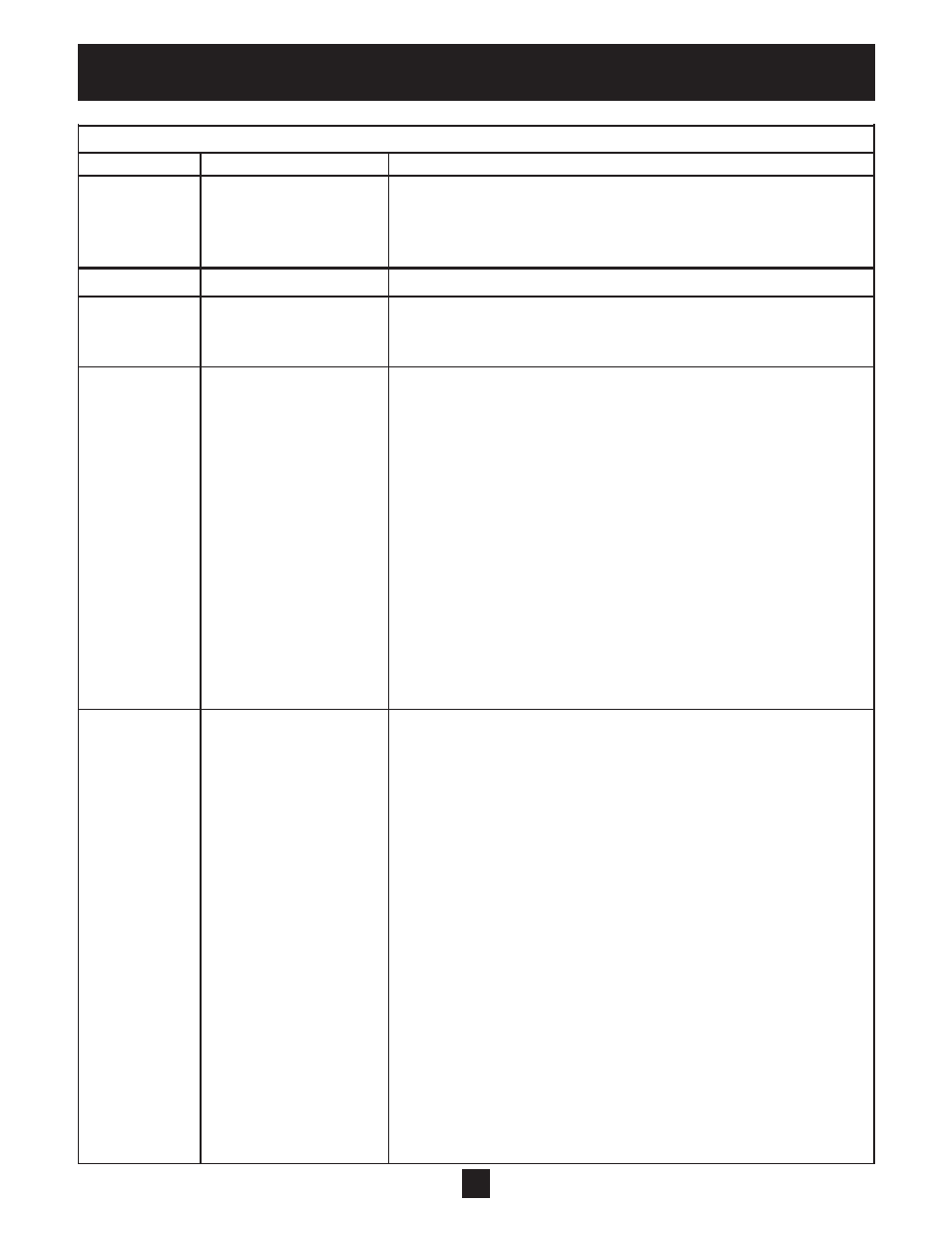

Troubleshooting

Orange Light Codes

Flashes

Controller Status

Description

Constant

Low Input Voltage

Constant orange light indicates the system input voltage is low. For

230V units, the orange light will be indicated when the input voltage

is between 140Vac and 170Vac. For 460V units, the orange light will

be displayed when the input voltage is between 140Vac and 310Vac.

Red Light Codes

Constant

Controller Error

Internal controller fault. The controller may be internally damaged.

Red

Verify the error by turning power off, waiting 5 minutes then apply

power. If the error persists, replace controller.

2 Blinks

No Water/Loss Of Prime

This fault can be caused by:

• Water supply level in well falls below suction inlet of pump.

• Plugged suction screen.

• Restriction in pipe between pump and pressure sensor.

• Air bound pump.

• Deadheaded pump, pump running against a closed valve.

• Filling long irrigation lines on start-up

• Incorrect setting of Motor Overload Setting switches.

In systems where the motor operates at less than Service Factor

Amps the controller may show a false No Water/Loss of Prime

fault. Reducing the motor overload setting will eliminate the

false readings.

If problem persists, please verify supply capacity.

The controller will automatically restart according to the No Water

Restart Time switches.

3 Blinks

Sensor Fault

This fault can be caused by:

• Disconnected sensor. Disconnect sensor from sensor cable

connector and reconnect to ensure a good connection.

• Disconnected sensor cable lead inside the controller. Check for

loose wires where the sensor cable connects to the circuit board by

tugging on each wire.

• Broken wire in the sensor cable.

• Miswired sensor cable. Check that the wires are connected to the

correct terminals on the control terminal block. Connect terminal

7 (24VDC SUPPLY) to the Brown wire. Connect terminal 6 (TRANSDUCER

INPUT) to the White wire. Connect the drain wire to chassis.

• Failed sensor. To diagnose this failure a meter capable of reading

milliamperes (mA) and DC voltage (VDC) is required.

- Set the meter to read DC voltage (VDC)

- Place the black lead on terminal 5 (COM) and the red lead on

terminal 7 (24VDC SUPPLY)

- If functioning properly, the DC voltage will be 24VDC +/- 15%. If

this voltage is not present, disconnect all control terminals and

repeat the measurement. If voltage does not recover, replace

controller.