A caution, Fig. 27 — condenser fan adjustment – Carrier 09DK054-084 User Manual

Page 29

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

START-UP

System Evacuation and Dehydration

— Refer

to GTAC II, Module 4, “Dehydration for Proper Evacua

tion and Dehydration techniques.”

Charging Procedure

— Charge to a clear sight glass.

Refer to GTAC II, Module 5 “Charging, Recovery, Recy

cling, and Reclamation” for proper charging techniques.

Add 10 lbs (4.5 kg) of R-22 over clear sight glass to flood

subcooler sections of the condenser coils. This 10 lbs

(4.5 kg) is added to the total unit charge, and must be pro

portioned by the percentage of circuits when multiple cir

cuits are employed. For example, in Table 2, add .67 x

10 lbs (4.5 kg) (approximately 6.7 lbs [3.0 kg]) for the 67%

circuit. Refer to Table 6 for condenser coil refrigerant

circuit data.

Check Operation of Condenser Fan Motor Con

trols and Rotation of Fans —

Rotation should be

clockwise as viewed from top of unit.

A

CAUTION

Before starting unit, be sure wire fan guards are

secured in place over each fan; personal injury may

result.

SERVICE

Cleaning Condenser Coils

— Clean coils with a vac

uum cleaner, fresh water, compressed air, or a bristle brush

(not wire). Units installed in corrosive environments should

have coil cleaning as a part of a planned maintenance sched

ule. In this type of application, all accumulations of dirt

should be cleaned off the coil.

A

CAUTION

Do not use high-pressure water or air. Damage to fins

may result.

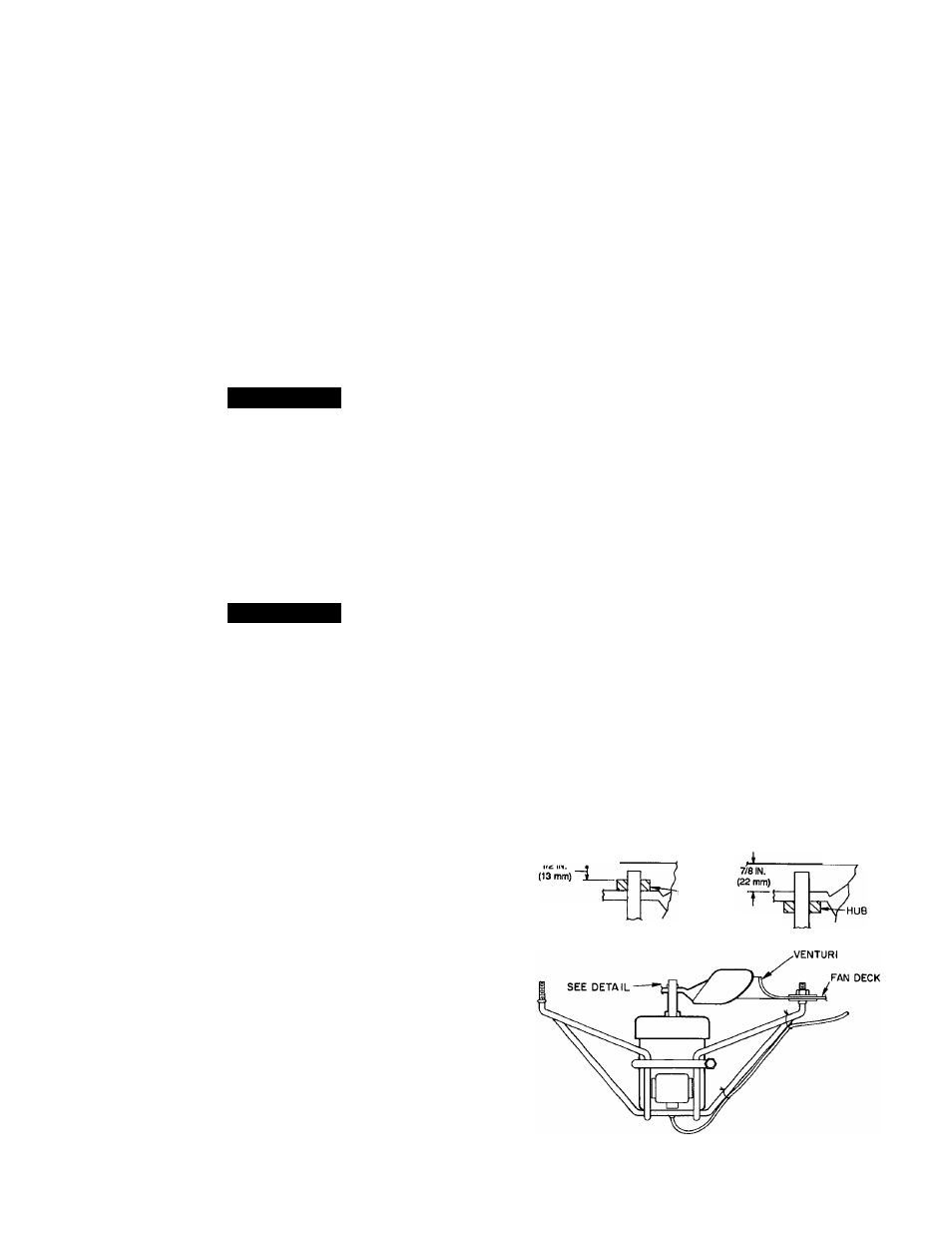

Condenser Fans

— Each fan is supported by a formed

wire mount bolted to the fan deck and covered with a wire

guard. The exposed end of the fan motor shaft is protected

by grease. If the fan motor must be removed for service or re

placement, be sure to grease fan shaft, and reinstall fan guard.

For proper performance, fan should be 7/8 in. (22 mm) be

low the top of the venturi on the fan deck for 60 Hz units,

and 1/2 in. (13 mm) to top of the fan hub for 50 Hz units.

Tighten set screws to 15 ± 1 ft-lbs (20 ± 1 . 3 N-m). Fig

ure 27 shows the proper position of the mounted fan.

IMPORTANT: Check for proper fan rotation (clock

wise viewed from above). If rotation needs to be re

versed on one motor, disconnect main power supply

and switch motor leads at the fan contactor. If rota

tion needs to be reversed on all motors, disconnect

main power supply and switch two leads at TBl.

Lubrication

— Fan motors have permanently lubricated

bearings.

Head Pressure Control

— Reduce condensing capac

ity under low ambient temperature conditions. See Fan

Cycling section below.

FAN CYCLING — Efficient operation of evaporator ther

mostatic expansion valves require a 90 F (32 C) minimum

saturated condensing temperature when compressors are op

erating at 100% capacity, 80 F (27 C) for 75% compressor

capacity, and 70 F (21 C) for 50 and 25% compressor

capacity.

The capacity of an air-cooled condenser increases with

increased temperature difference (defined as entering satu

rated condenser temperature minus entering outdoor-air tem

perature) and decreases with decreased temperature differ

ence. A drop in entering outdoor-air temperature results in

a lower saturated condensing temperature. When outdoor-

air temperature drops below the minimum temperatures listed

in Table 7 for standard units, additional head pressure con

trol is required.

Model 09DK units have fully automatic intermediate-

season head pressure control through condenser fan cycling

using electromechanical fan cycling controls. Standard head

pressure controls will control the 100 and 50/50% con

denser capacity applications. Head pressure can also be con

trolled by fan cycling controls supplemented by the acces

sory Motormaster® III solid-state head pressure controller.

See Motormaster III installation instructions for more infor

mation. Other circuit split applications (67/33, 33/33/33,

33/33/17/17% capacity splits) will require the accessory fan

control kit which includes a control panel and additional

fan cycling pressure switches. See fan control installation

instructions for more information.

In the standard control scheme, fans 1 and 2 will be on

when there is a call for cooling from the respective coil cir

cuits. Fans 1 and 2 are non-cycling. On 054 and 064 units,

fans 3 and 4 will be controlled by using a fan cycling pres

sure switch on each of the primary coil circuits in response

to condensing pressure. On 074 and 084 units, fans 3 and 4

will also be controlled using a fan cycling pressure switch

in each of the primary coil circuits in response to condens

ing pressure. Fans 5 and 6 will be controlled by using two

air temperature switches, which respond to the outdoor am

bient temperature. The air temperature switches are located

on the control box shelf. For temperature and pressure set

ting details, see Table 8.

With respect to the fan cycling pressure switch control,

fans 3 and 4 are on above 260 ± 15 psig (1793 ± 103 kPa)

and off below 160 ± 10 psig (1103 ± 69 kPa). If pressure

is rising between 160 psig (1103 kPa) and 260 psig

(1793 kPa), fans 3 and 4 are off. If pressure is reducing

from 260 psig (1793 kPa) to 160 psig (1103 kPa) fans 3 and

4 are on. With respect to the air temperature switch control

on the 074 and 084 condensers, below 70 ± 3° F

(21.1 ± 1.7° C) outdoor ambient, fans 5 and 6 are off; above

80 ± 3° F (26.7 ± 1.7° C) fans 5 and 6 are on. Between

70 F (21.1 C) and 80 F, (26.7 C) whether fans 5 and 6 are

on or off depends on whether temperature is rising or fall

ing. If the temperature is rising from 70 F (21.1 C) to 80 F

(26.7 C), fans 5 and 6 are off. If the temperature is falling

from 80 F (26.7 C) to 70 F (21.1 C), fans 5 and 6 are on.

TOP OF VENTURI

ON FAN DECK

TOP OF VENTURI

ON FAN DECK

L

HUB

ALL 50-Hz

UNITS

ALL 60-Hz

UNITS

29

NOTE: Fan rotation is ciockwise as viewed from top of unit

Fig. 27 — Condenser Fan Adjustment