Fig. 13 — fan cycle pressure switch – Carrier 09DK054-084 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

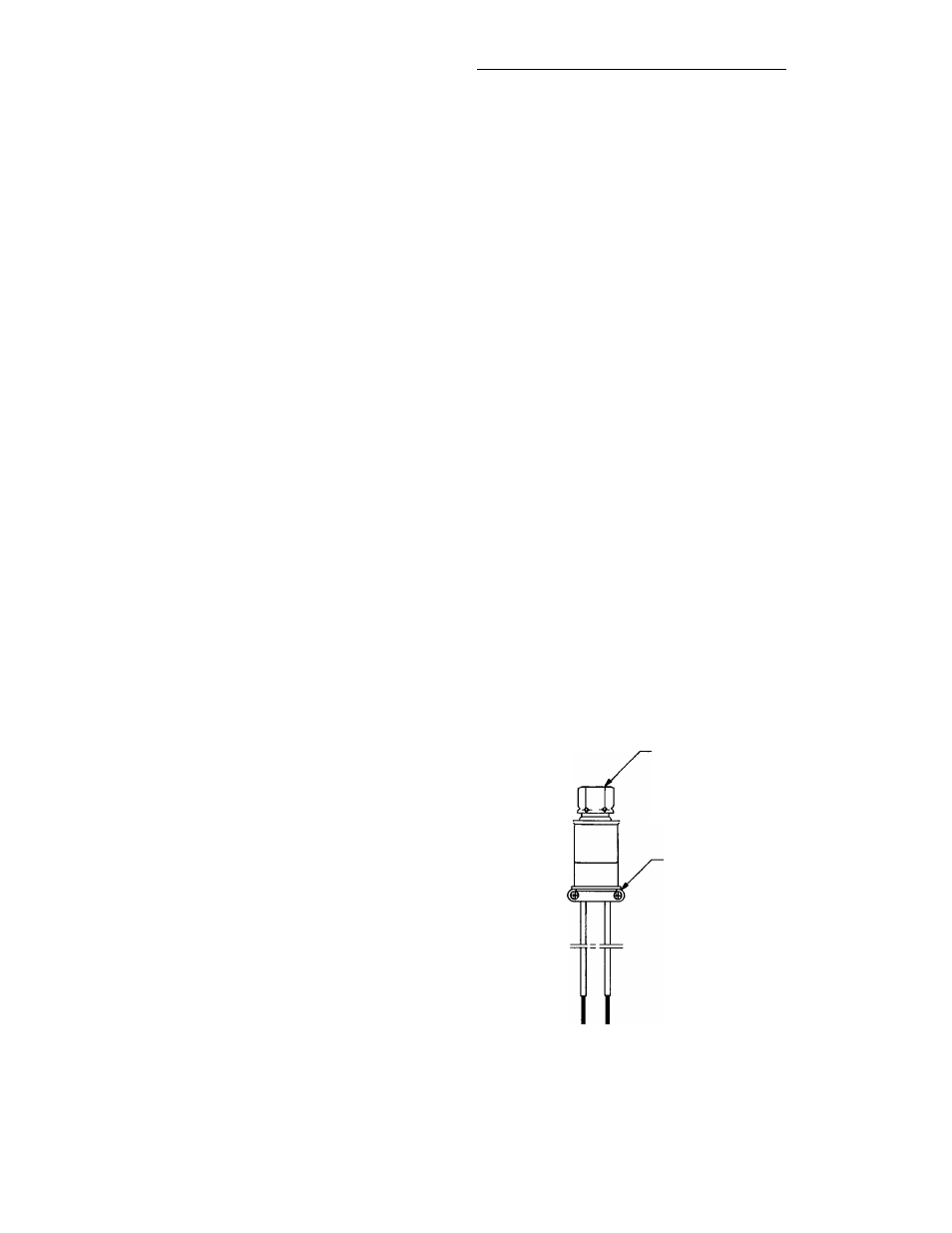

2. Install Fan Cycle Pressure Switches and Clamps — Four

FCPSs should be used. Locate holes, valve core assem

blies, and FCPS’s 1, 2, 3, and 4 at the specified locations.

See Fig. 8. Insert valve cores into valve core bodies by

threading into place and tightening to 1.5 to 3 in.-lb (169.5

to 339 mN-m). The additional two FCPSs and valve core

assemblies are provided with the accessory fan control kit.

Cut the 3/8-in. field-supplied FCPS conduit at a desired length

to fit between each FCPS location and the junction box on

the unit. See Fig. 11 for typical conduit installation. Feed

FCPS wires through each conduit and secure at the switch

by utilizing each conduit connector. See Fig. 13. Secure

the conduit at the junction box with 3/8-in. field-supplied

conduit connectors. Wire the FCPSs according to Fig. 14

and 18. Note that FCPS2 and 4 and FCPSl and 3 are wired

in parallel. Fans 3 and 4 are being shared by two different

refrigeration circuits. If either refrigeration circuit needs the

fan to be on, it will be on. Clamp all lines to brackets sup

plied on the unit.

REFRIGERANT LINE SIZING - Sizing depends on length

of lines between various sections of the refrigerant system.

See Fig. 9 for coil connection details. Consider the amount

of liquid lift and drop in the system as well as proper com

pressor oil return. See Liquid Lift section for more infor

mation. Consult Carrier System Design Manual, Part 3, or

Carrier E20-II Refrigerant Piping Computer Program for proper

piping sizes and design

LIQUID SHUTOFF VALVE AND SIGHT GLASS - A

shutoff valve is not supplied with 09DK condensers. It is

strongly recommended that a full line size liquid shutoff

valve be field supplied near condenser to allow for servic

ing parts of the refrigerant circuit A field-supplied mois

ture indicating sight glass is recommended for use in charg

ing and servicing the system. Refer to Fig. 7.

PRESSURE RELIEF - The ASHRAE Standard 15, Safety

Code for Mechanical Refrigeration states; “Every refriger

ating system shall be protected by a pressure relief device

or some other means designed to safely relieve pressure due

to fire or other abnormal conditions ” Since 09DK con

densers do not have pressure relief devices, one must be

field supplied and installed just before the liquid line ser

vice valve. (See Fig. 7.) When the split coil is used with

multiple systems, each system must have its own pressure

relief.

REFRIGERANT RECEIVER — A refrigerant receiver is

not

furnished with 09DK condensers and is not recom

mended for normal applications as its use will be detrimen

tal to the desired effects of subcooling. However, if a par

ticular application requires a receiver to increase refrigerant

holding capacity of the condenser, a receiver can be used.

When a receiver is to be used year-round, it should be in

stalled indoors. Carrier recommends the following installa

tion in such a case (see Fig 24): locate valves on each side

of the receiver so receiver may be isolated from system for

normal operation.

Procedure for Using the Refrigerant Receiver — See

Fig. 24.

1. During normal operation — Valve A is open and valves

B and C are closed. Receiver is isolated from the

system.

2. For servicing — Valves A and C are closed and valve B

is open. Run unit until all the refrigerant is in the re

ceiver and then close valve B. Unit is now ready for ser

vicing.

3. To resume operation — Leave valve A closed and open

valves B and C. Run unit until the stored refrigerant is

drawn into the system. To completely remove the re

frigerant from the receiver, throttle valve B while noting

condition of refrigerant in the liquid line sight glass; also,

watch the suction pressure. A sudden surge of bubbles

in the sight glass and a rapid decrease in suction pres

sure indicates that all the refrigerant has been withdrawn

from the receiver. Immediately close valves B and C

and then open valve A. The unit should now be ready

for normal operation, with the receiver isolated from the

system. The system should be charged to a clear sight

glass when under normal operation.

LIQUID LIFT — Amount of liquid lift available before re

frigerant flashing occurs depends on amount of liquid sub

cooling in the system.

All 09DK condensers have positive subcooling when ap

plied with optimum charge. With subcooling, it is possible

to overcome an appreciable friction drop and/or static head

(due to elevation of the liquid metering device above the

condenser).

When 09DK condensers are applied with minimum charge,

no positive subcooling in condenser is realized; therefore,

if subcooling is required it must be obtained by external

means such as a liquid suction interchanger.

The average amount of liquid lift available is shown in

Table 3 for refrigerants R-22, R-502, and R-134A. Avail

able subcooling is greatly reduced when R-12 and R-500

are used in these units. It is recommended that the evapo

rator be at the same level as the condenser, or lower.

1/4 SAE FLARE WITH

56 (14 2) HEX

CONDUIT

CONNECTOR

SAE

— Society of Automotive Engineers

Fig. 13 — Fan Cycle Pressure Switch

18