Carrier 09DK054-084 User Manual

Page 28

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAIN POWER WIRING — These units must have ade

quate overcurrent protection, fuses, or HACR (Heating, Air

Conditioning and Refrigeration) breakers, according to the

national and applicable local codes.

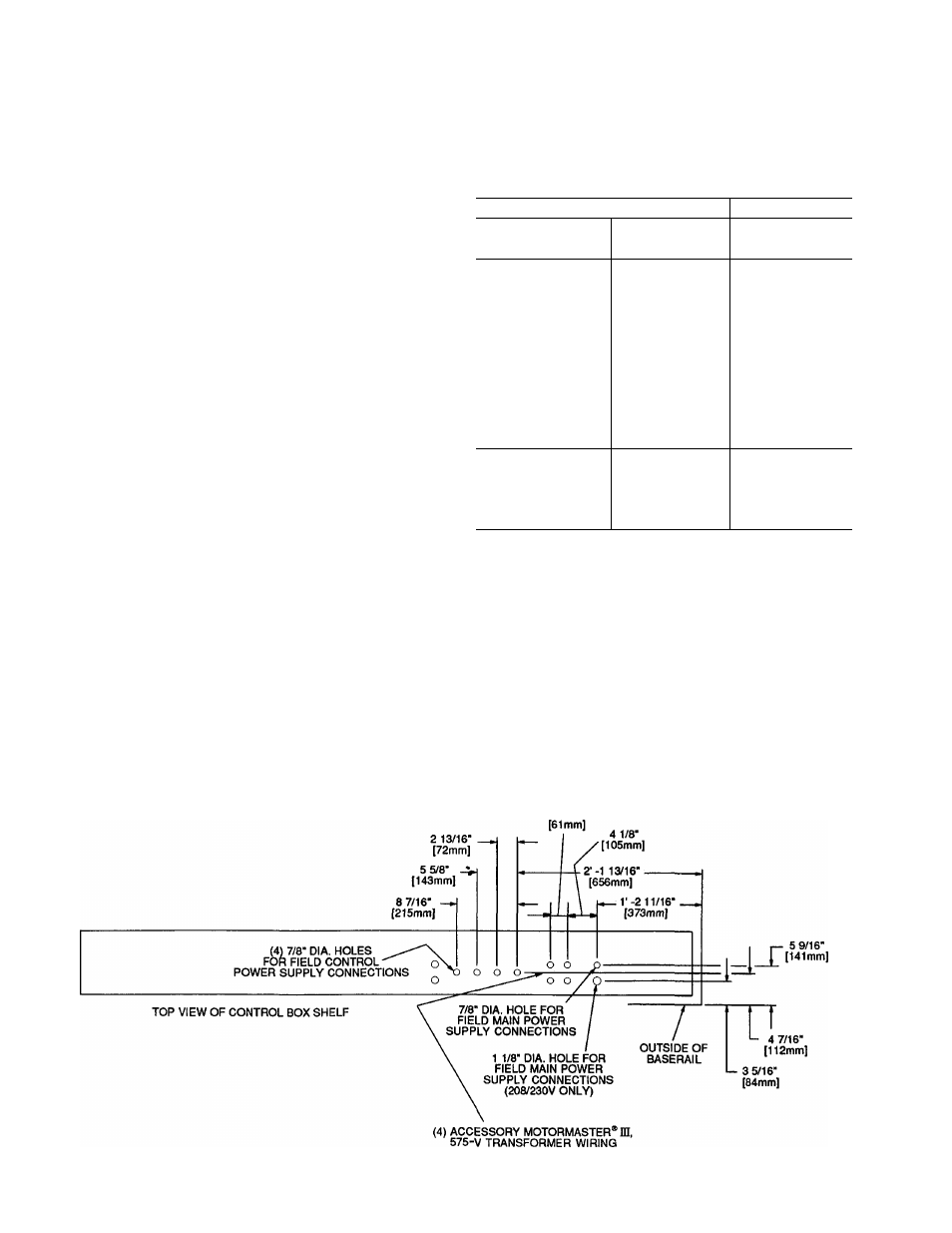

For field power connections, all main power wiring en

ters the unit through a factory-punched access hole under

the control box. Two access holes are provided, the larger

should be used for 208/230 v applications. See Fig. 26.

Wiring must be rated at 75 C minimum. Use copper, copper-

clad aluminum, or aluminum conductors. Field power sup

ply connections are made at terminal block 1 (TBl). Max

imum incoming wire size for each terminal connection on

TBl is 2/0, and all power wiring must comply with appli

cable local and national codes. Refer to the unit power cir

cuit information to determine incoming wire sizes. (See

Table 4.) Refer to Table 5 for American and European wire

conversion information.

CONTROL CIRCUIT POWER WIRING - Provide a sep

arate single phase power source for each control circuit (de

pending on the coil refrigerant circuit split), with the re

quired overcurrent protection (fuses or circuit breakers). See

Table 4 for control circuit overcurrent protection amps.

For field control circuit connections, units are factory wired

for a 50/50% capacity split and would utilize terminal blocks

2 and 3 (TB2 and TB3). TB2 will control fans 1, 3, and 5;

TB3 will control fans 2, 4, and 6. Fans 5 and 6 are on 074

and 084 units only. If 100% condenser application is re

quired, connect the factory supplied jumpers from TB2-1 to

TB3-1 and from TB2-2 to TB3-2, and bring incoming con

nections to either TB2 or TB3. Factory-punched access holes

under the control box are provided for the incoming wires.

See Fig. 26 for access hole details. Terminal block connec

tions utilize no. 8 screws. Wiring must be class 1, 14 AWG

(American Wire Gage) copper conductors only. Power re

quired for control circuits is 100 va. See Table 4 for control

circuit voltage data.

GENERAL WIRING NOTES

1. Power entry is at one end only.

2. Fan motors are thermally protected. Three-phase motors

are protected against primary single-phasing conditions.

3. Replacement of factory wires must be with appliance

wiring material, rated 105 C, or its equivalent.

4 Factory wiring is in accordance with NEC. Field mod

ifications or additions must be in compliance with all

applicable codes.

DESCRIPTION OF CONTROLS - The condenser units

utilize a dual voltage control scheme: a 3-phase power cir

cuit for the fan system operation and a single-phase control

circuit voltage for fan cycling control. The number of con

trol circuit voltages will depend on the coil split application

used. See head pressure control description in the service

section for a detailed description of the controls function.

Table 5 — American/European Wire Conversions

AMERICAN

EUROPEAN

Industry

Standard Size

American

Conversion

(mm^)

Industry

Standard

Size (mm^)

18 AWG

0.82

1.0

16 AWG

1 30

1.5

14 AWG

2.08

2.5

12 AWG

3 30

40

10 AWG

5 25

60

8 AWG

6.36

100

6 AWG

13.29

16.0

4 AWG

21.14

25.0

3 AWG

26.65

—

2 AWG

33.61

35 0

1 AWG

42.39

50.0

1/0 AWG

53.49

—

2/0 AWG

67.42

70.0

3/0 AWG

85.00

95.0

4/0 AWG

107.19

120.0

250 kcmil

126 64

150.0

300 kcmil

151 97

—

350 kcmil

177 90

185 0

400 kcmil

202 63

240 0

500 kcmil

253 29

300 0

600 kcmil

303 95

—

LEGEND

AWG —

American Wire Gage

kcmil —

Thousand Circular Mils

Step 5

—

Add Accessories As Needed

— The

following accessories are available for the 09DK054-084

condensers: fan sound reduction kit, condenser coastal coil

filter, security grille package, condenser coil hail guard pack

age, accessory control transformer, Motormaster® III de

vice, Motormaster III Relay/Sensor Kit, and accessory fan-

control kit. Winter Start and any special electrical interlock

must be considered separately. Refer to installation instruc

tions furnished with each accessory for more information.

2 13/32"

Fig. 26 — Power Wiring Access Holes; 054-084 Units

28