Top Flite TOPA0305 Part 2 User Manual

Page 29

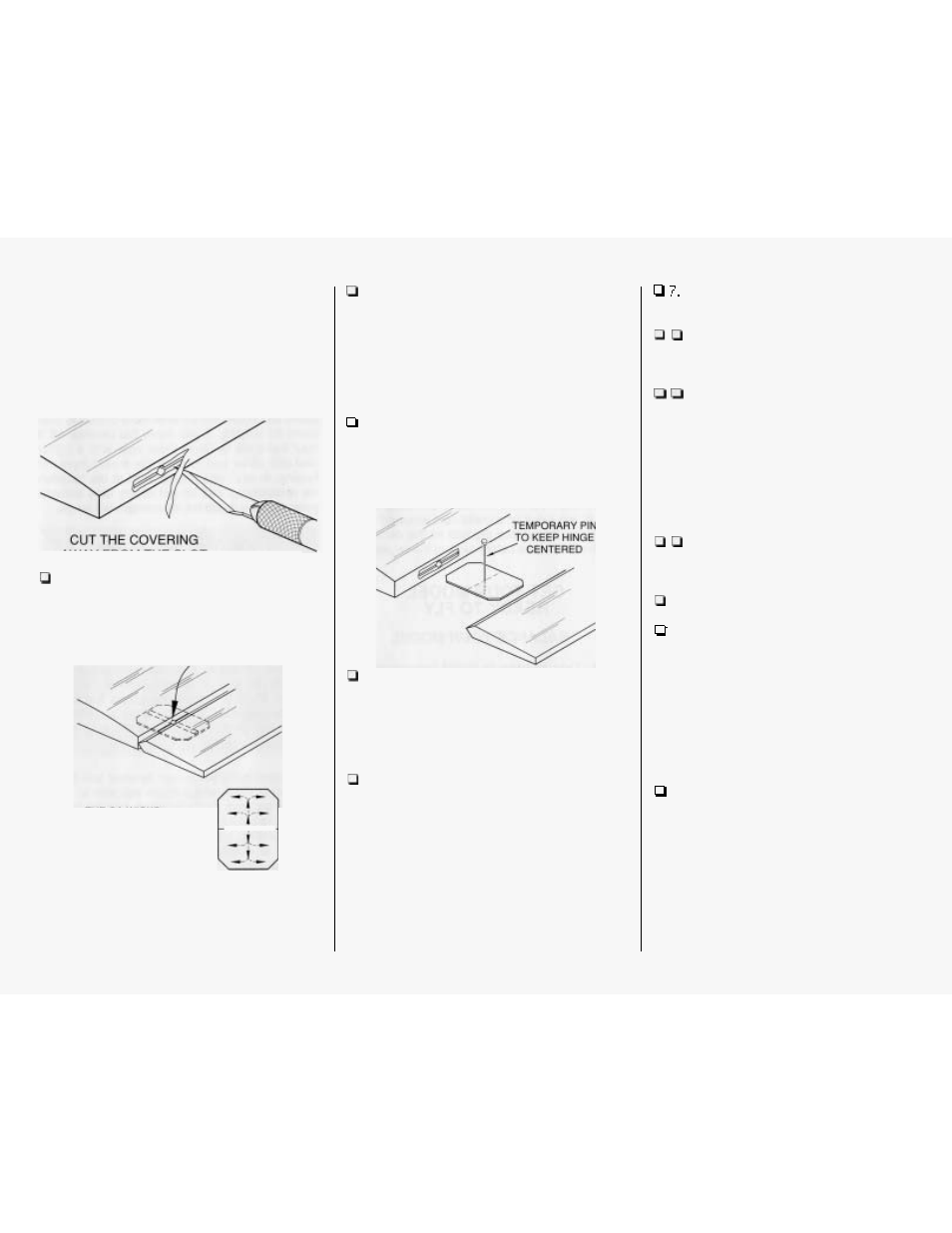

JOIN THE CONTROL SURFACES

(HINGING)

These instructions mention the V-tail which uses

two torque rods instead of a single joiner wire as

used on the straight-tail.

If you're building the

straight tail, follow these instructions except where

the torque rods are mentioned.

AWAY FROM THE SLOT

1.

Start with the stab and elevators. Remove a

small strip of covering from the hinge slots. For the

V-tail, remove a small strip of covering where the

plastic bearing tubes contact the TE.

ASSEMBLE, THEN APPLY

6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

_ _ I _ _

THE CA WICKS

ALONG THE "TUNNELS"

TO THE ENTIRE

HINGE SURFACE

Q2.

Drill a 3/32" hole 1/2" deep in the center of the

hinge slots on the stab and elevators. A high speed

Dremel

Tool@

with

a

cutting burr works best for this,

but you can use a drill or a sharpened brass tube

instead.

3.

If you are building the V-tail, use coarse

sandpaper to roughen the part of the torque rods

that will be inserted into the ruddervators and the

plastic bearing tubes.

If you are building the

straight-tail, roughen the joiner wire. Use a

toothpick to dab a small amount of petroleum jelly

on the ends of the V-tail plastic bearing tubes to

keep epoxy out.

4.

Fit the hinges in only the stab or elevators

(without glue). Fill the torque rod holes in the

elevators with 30-minute epoxy. Install the torque

rods in the elevators. Wipe away excess epoxy

with a cloth dampened with alcohol.

5. Join the elevators to the stab with the hinges.

If necessary, insert a pin in the center of the hinges

to keep them centered in the elevator and stab.

Make sure there is approximately a 1/64" gap

between the elevators and the stab

so

you do not

glue them together.

6. Cut a paper towel into 2" squares. Add six

drops of thin CA to the center of the hinges on

both the top and bottom.

Use the paper towel

squares to absorb excess CA from the hinge gap

before it cures.

Do

not use CA accelerator on any of the hinges

and do not glue the hinges with anything but

thin

CA.

Do

not attempt to glue one half of the

hinge at a time. The hinges will not be properly

secured and could come out while the model is

in flight.

-

65

-

Glue the bearing tubes to the TE with a dab of

30-minute epoxy.

8 .

Use the same hinging method to join the

rudder to the fin (if building the straight tail) and the

ailerons to the wing.

9. Thoroughly roughen the flap hinges with

coarse sandpaper. Mix enough 30-minute epoxy to

do one flap at a time. Use a piece of leftover wire to

thoroughly coat the holes in one of the flaps and

the holes in the wing with the epoxy. Coat one side

of the flap hinges with epoxy and insert them into

the wing. Coat the other side of the hinges with

epoxy and join the flap. Wipe away excess epoxy

before it cures.

10.

Position the flap and the hinges

so

the

flap is centered and fits the wing. Tape the flap in

place until the epoxy is fully cured.

11.

Join the other flap to the wing the same way.

12.

Reinstall any pushrods you may have

disconnected while covering, and mount the control

horns to the ailerons.

GLUE IN THE WINDOWS

1.

Use a special canopy glue such as

J

&

Z

Products

Z RC/56 (JOZR5007) to glue the windows

to the cabin top. This kind of glue is formulated for

plastic and dries clear. Wipe away excess glue with

a

tissue dampened with water before it dries. Use

masking tape to hold the windows to the inside of

the cabin top until the glue is dry.

If you decide to

use CA, use medium CA (not thin). Use it

sparingly

and

do not

use accelerator.