Top Flite TOPA0305 Part 2 User Manual

Page 22

aft cabin former and F7A. The thickness of the

cardboard should be approximately 1/64" or .015".

This is to provide a little clearance for painting and

covering. Trace the outline of F7A onto the piece of

cardboard. Cut approximately 1/4" outside of the

line you drew. Reposition the cardboard shim and

glue the aft cabin former to the crutch with the shim

in place.

11. Make a shim and glue the front cabin former

to the crutch the same way.

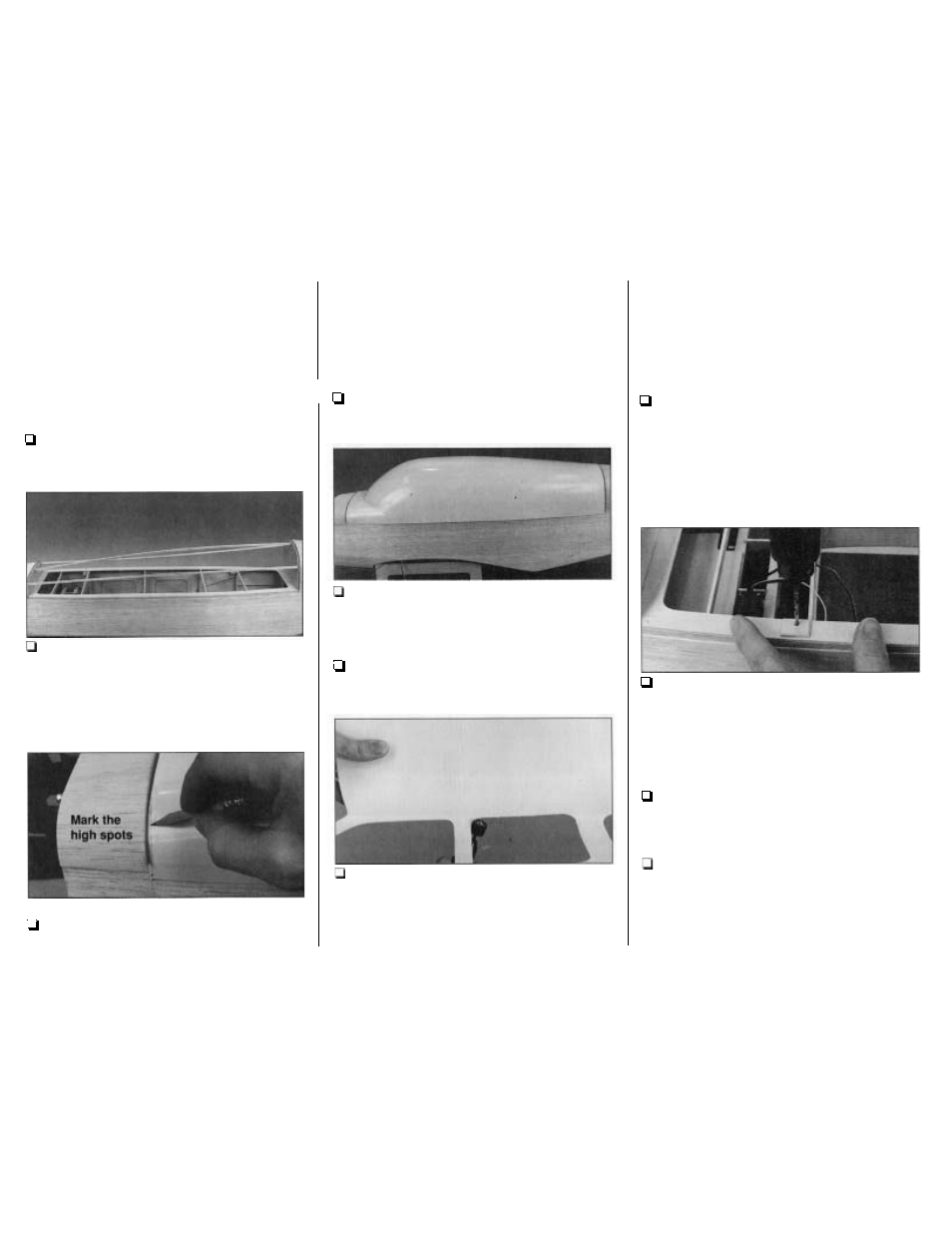

12.

Temporarily position some balsa sticks

between the front and aft cabin formers to make

sure they and the shims tightly contact the fuse.

You are going to fit the cabin top to the shims

so

the more accurately they fit the fuse, the more

accurately your cabin top will fit the fuse.

13.

Position the cabin top on the fuse so the

front contacts the cardboard shim and the

centerline on the cabin top aligns with the

centerline on the fuse. Use a lead pencil to mark

areas of the front of the cabin top that need to be

sanded for a perfect fit. Carefully

and

lightly sand

the areas you marked, erase the pencil marks, and

reposition the cabin top. Continue to mark, sand

and fit the cabin top until the front fits well.

14. Perform the same procedure to the aft edge

of the rear of the cabin top until it fits the rear

cardboard shim and the cabin top drops into place.

15.

With the cabin top on the fuse, make your

pencil marks where the bottom needs to be

trimmed. Sand the bottom edges of the cabin top

until it fits.

16. Thoroughly roughen the entire inside of the

cabin top with 220-grit sandpaper

so

glue and paint

will stick.

17.

Use a Dremel tool with a carbide cutter or a

similar type of rotary tool, or small scissors to cut

the window openings along the cutlines inside the

cabin top. The window outlines in the cabin top are

about 1

/16

smaller than the windows themselves.

This will allow you to accurately fit the windows

later, but do not enlarge the openings yet - just

roughlycut them along the cutlines for now.

MOUNT THE CABIN TOP

1. Remove the screws that temporarily hold the

crutch to the fuse.

Glue four

pieces of

3/4"

x 3/4" leftover 1/8" plywood to the crutch over

the holes. Using the holes in the crutch as a guide,

drill 1/16" holes up through the 1/8" ply pieces you

just glued on. Temporarily screw the crutch to the

fuse with the screws.

2. One at a time, remove a screw, and enlarge

the hole through the crutch and the blocks in the

fuse with a 1/8" drill. After you drill each hole

temporarily insert a 4-40

x 3/4" Phillips head screw

to hold the crutch in alignment as you drill the rest

of the holes.

3. Remove the crutch from the fuse and press

4-40 blind nuts into the holes in the top of the

crutch. Glue them with a little thin CA.

4. Lightly spray the edges of the crutch and

crutch formers F7B and F2B with CA accelerator.

Place the crutch on the fuse with the cardboard

shims. Slip a piece of wax paper between the shim

and crutch formers at the back and front of the

crutch. Fasten the crutch to the fuse sides with four

58-