Gear – Top Flite TOPA0305 Part 2 User Manual

Page 16

MOUNT THE NOSE LANDING GEAR

Continue with these instructions if you are

installing fixed landing gear. If you are

installing retracts, skip to Retractable gear on

page 53.

Fixed

gear

I

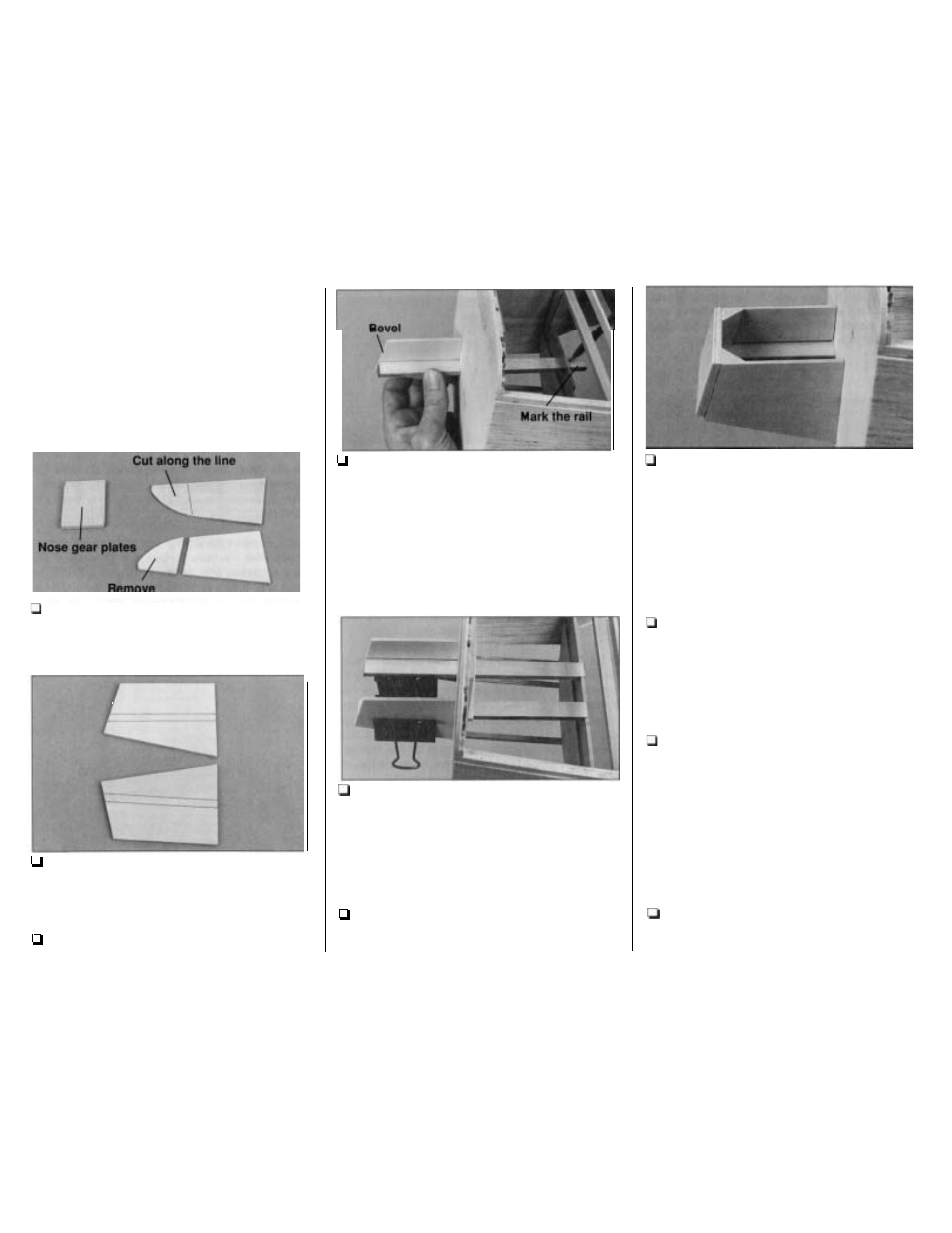

F1.

Draw a line connecting the punch marks on

both die-cut 1/8" plywood nose landing gear

braces. Cut the braces off at the line. Glue the two

die-cut 1/8" plywood nose gear plates together.

F2.

Place the braces over their location

on the

plan. Mark the location of the 1/4" plywood landing

gear rails onto the braces.

F3. Remove the engine mount from the firewall.

F4.

Cut a bevel on the end of the 1/4" x 9/16"

x

9"

plywood landing gear rails to match the angle

on the end

of the braces. Test fit a rail through the

right side of the firewall and in the notch in former

F2. Position the right brace and align the front of

the rail with the front of the brace. Mark the rail 1/8"

aft

of former F2. Remove the rail and cut it at

the mark. Mark the other rail in the same manner.

F5.

Use 30-minute epoxy to simultaneously glue

the rails to the firewall and former F2, and the rail

braces to the rails and the firewall. Make sure the

front of the rails are even with the front of

the braces.

F6.

Drill 1/8" holes through the punch marks in the

nose gear plate. Press four 4-40 blind nuts into the

holes in the plate, and secure them with thin CA.

-

52

-

F7.

Position the nose gear plate on the front of

the braces. Trim the rails

so

the blind nuts do not

interfere. Use 30-minute epoxy to glue the nose

gear plate to the rails and rail braces. Hold the

plate in position with masking tape until the epoxy

is fully cured. Add balsa triangle braces as shown

on the plan cut from leftover fuse corner stringers.

See the photo at step 11.

F8. Mount the nylon nose gear bearing to the

nose plate with four 4-40

x 1/2" screws. Enlarge

the holes in the nose gear bearing for the nose

gear strut with a #10 drill bit (if you don't have a

numbered drill set, an 11/64" drill bit will work too).

F9. Enlarge the outer hole in the black, nylon

steering arm with a # 41 drill bit or a hobby knife.

Mount the heavy duty Screw-Lock connector to

the steering arm with the one-way star washer.

Mount the 3 / 1 6 nose gear wire to the nose gear

bearing with a 3/16" wheel collar and set screw

and the steering arm and a 6-32

x 1/4" socket head

cap screws as shown on the plan. Notice that the

steering arm is slightly off center when the nose

gear is centered.

FIO. Temporarily fit your nose steering servo

and tray on the forward servo rails. Fit a servo arm

to

your servo.