Top Flite TOPA0305 Part 2 User Manual

Page 18

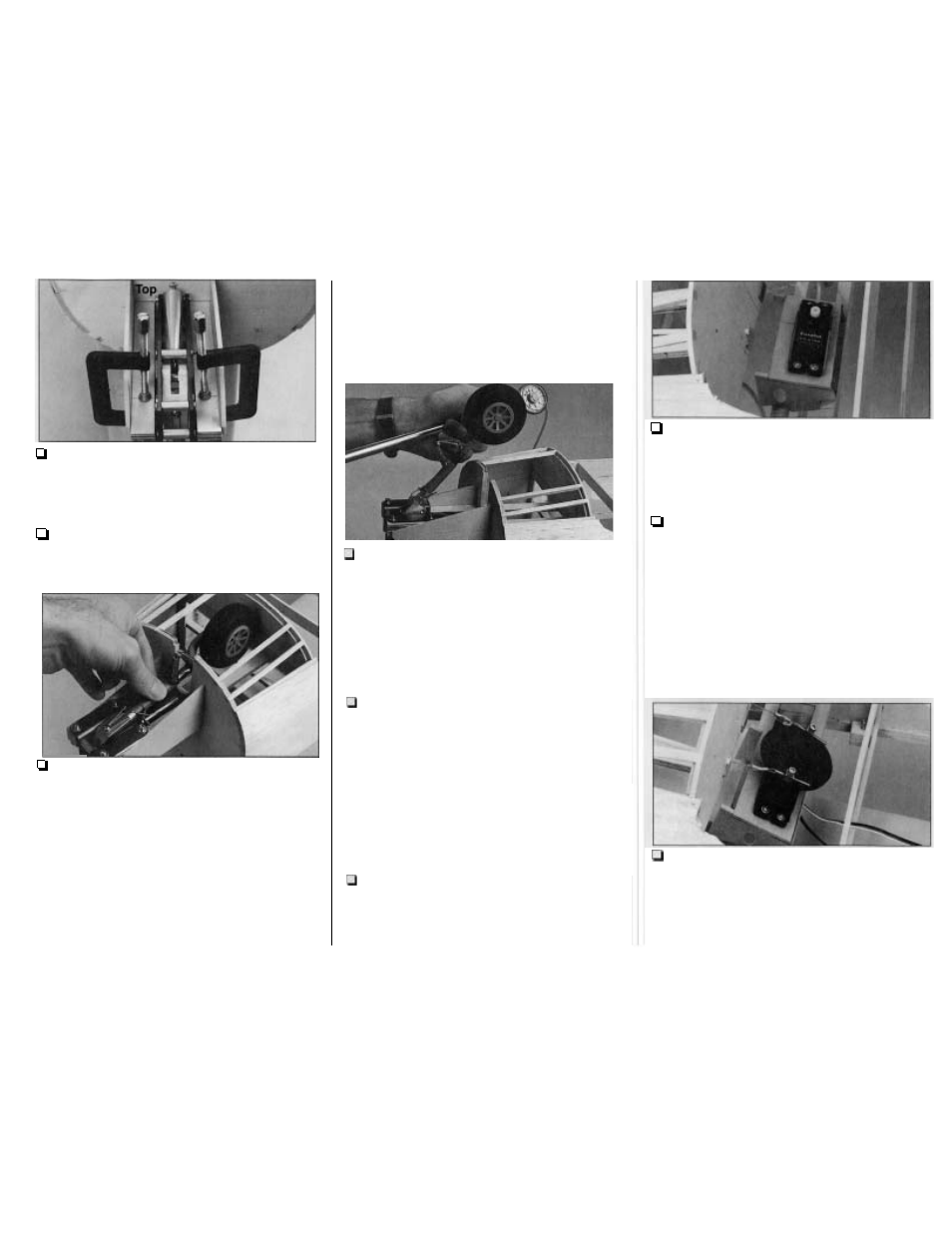

R5. Use small clamps to hold the nose gear to

the rails

so

the pivot point (on the Robart 631's)

aligns with the marks you made on the top of the

rails. Mark the locations of the mounting holes on

the landing gear rails.

R6. Remove the landing gear and drill 5/32"

holes at the marks you made. Temporarily mount

your landing gear with 6-32

x 3/4 screws and blind

nuts (not included).

R7.

Remove the two 3/16" stringers that

interfere with the wheel and strut. Use a Dremel

Tool or a razor saw to cut the firewall to

accommodate the strut. Retract the nose gear and

make sure it does not interfere with the firewall.

Note:

Adjust the

centering spring

on your retracts

so

the nose wheel is neutral and make sure the

nose wheel is centered on the strut. On the Robart

631 strut we inserted two #8 washers between the

wheel and the strut to center the wheel. The nose

wheel

must

be

neutral

and

centered

to fit

between the rails when retracted.

Hint:

File or sand a slight bevel to the bottom

edges of the rails to guide the nose wheel, in case

R8. If you have your air pump and some quick

disconnects handy, temporarily connect them to

your nose gear air cylinder and actuate the nose

gear with the air pump. This will give you a good

indication of any problem areas that you can

U

R9.

Cut 3/16" off the aft edge of the die-cut 1/8"

plywood

nose steering servo tray.

Mount your

nose steering servo to the servo tray

so

the output

shaft is on the

left

side of the servo tray as shown

on the plan. See the photo at step R11. Note that

the servo is offset toward the aft edge of the servo

u

R10.

If

you would like to mount your air control

valve in the same location as in our prototype, drill

a 1/2" hole in the die-cut 118" plywood

right nose

steering servo tray mount

at the punch mark.

R11. Test fit the servo tray (with the servo) in the

die-cut 1/8" plywood

servo tray mounts

and fit the

assembly in the servo rails. Position the mounts

and the tray

so

the output shaft of the servo is

centered between the 1/8" holes in former F2. Glue

the servo tray and the mounts in this position.

R12. Cut two 4-5/8" pieces from the white nose

steering cable inner pushrod guide tube and slide

the pieces through the holes in the firewall and

former

F2.

Glue the tubes to the firewall and F2.

CONNECT THE NOSE

Several pull-pull steering cable systems are

available that will work in your Bonanza. We

selected the Sonictronics #121 Pro-Control Cable

System.

STEERING PULL-PULL

R1. Enlarge the hole in two Screw-Lock pushrod

connectors with a #46 or 5/64" drill bit. Mount the

screw-lock connectors to a large servo arm and

fasten each with a nylon retainer. Connect one end

of a 14" long pull-pull cable to a threaded rod

included with the pull-pull steering set using the

-54-

correct now.