Top Flite TOPA0305 Part 2 User Manual

Page 15

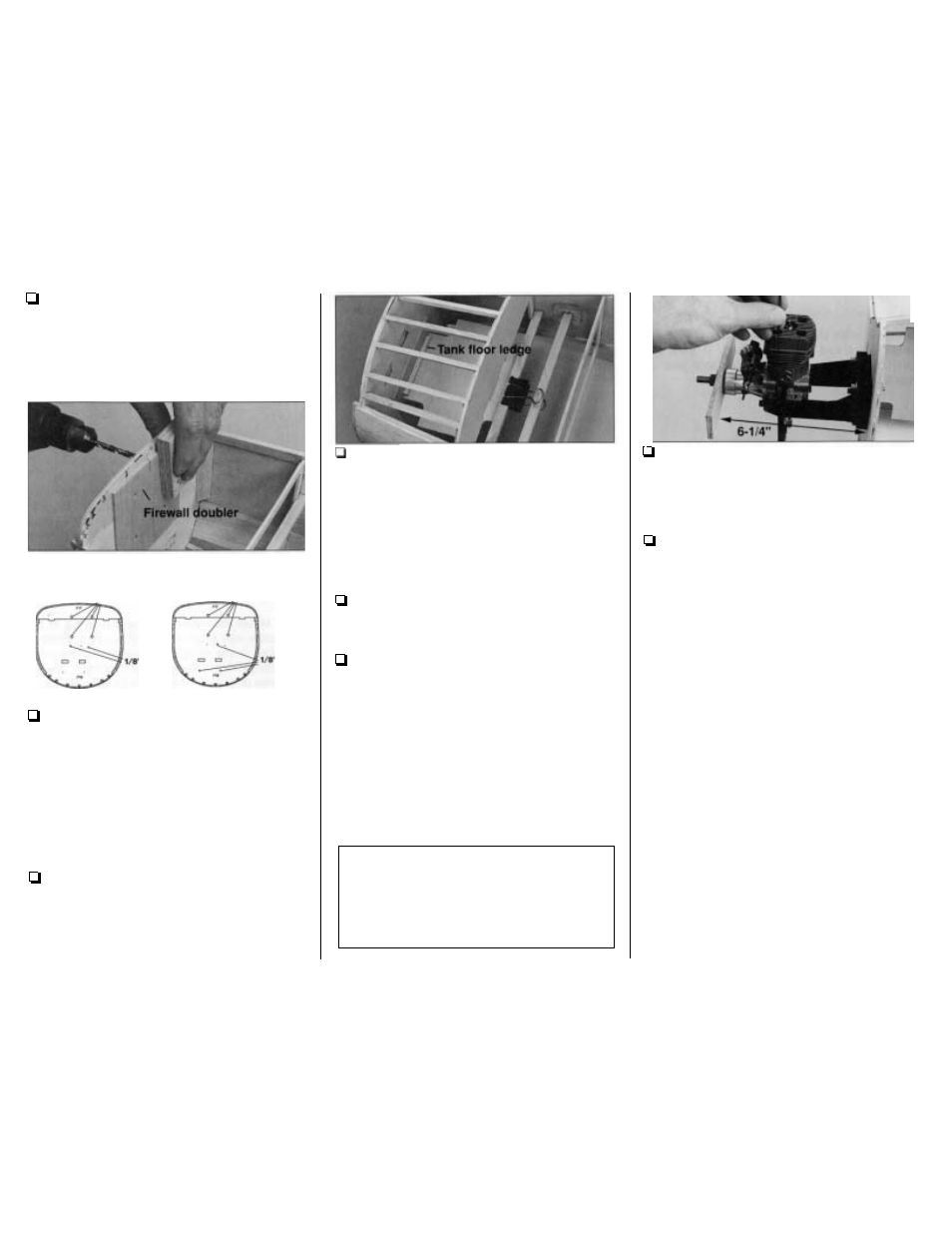

5 .

Glue the die-cut 1/8" plywood

firewall

doubler

to the back of the firewall, centered on the

engine mount punch marks, 1/8" below the notch in

the center of F1DT as shown on the plan.

FIXED LANDING GEAR

RETRACT LANDING GEAR

(VIEWED FROM THE FRONT)

IVIEWED FROM THE FRONT)

7/32"

7/32"

6. Drill the correct size holes through the punch

marks on the front of the firewall as shown in the

sketches above. Tightly hold a

thick

block of wood

on the back

so the drill does not split the wood

when it comes through.

7.

Press four 8-32 blind nuts into the holes on

the back of the firewall. Use an 8-32

x

1-1/2"

socket head cap screw with some large washers to

draw the blind nuts into the wood. Wick thin CA

around the back of the blind nuts to permanently

hold them in place.

8.

Temporarily clamp the die-cut

1/8"

plywood

tank floor

to the forward servo rail so it is centered

on the back of the firewall doubler. Turn the

fuselage over and push the tank floor up until it

contacts the edge of the bottom blind nuts. Glue a

3/16"

x

3/16"

x

3" balsa stick to the back of the

firewall under the tank floor to serve as a

forward

tank floor

ledge.

Do

not glue the tank floor to the

ledge until instructed to do so.

9. If you have not already done so, sand the

fuselage side doublers and fuselage sides

so they

are flush with the front of the firewall.

10. Cut the spacer bar off both

engine mount

halves and trim off any flashing

so they easily fit

together. Loosely bolt your engine mount to the

firewall with four 8/32

x 1-1/4" socket head cap

screws,

#8

lock washers and flat washers. Adjust

the mount so your engine will fit. Tighten the

screws to securely hold the mount to the firewall.

Use small clamps

to

hold your engine to the mount

so the front of the drive washer (or the back plate

of your spinner) is 6-1/4 from the firewall. Mount a

flat wood stick or the back plate of your spinner to

the engine so you can measure the distance.

Beech Fact: In addition to the aforementioned

benefits the V-tail offers, others include lower

manufacturing costs through fewer parts, fewer parts

for Beech dealers to stock, reduced damage from

debris thrown from the prop and wheels, and spin

recovery superior to that of an airplane with a

conventional tail.

11. Mark the engine mounting bolt holes on the

mount.

Hint:

Mark the holes with a wire rod

sharpened at one end. Heat the tip of the rod with a

torch to dimple the engine mount in the

center

of

the holes.

12. Remove the engine from the mount and the

mount from the firewall. Use a drill press,

if you

have access to one, or use a hand drill to drill the

holes with a #29 or 9 / 6 4 drill bit for 8-32 screws.

Tap 8-32 threads into the mount. Screw the mount

back onto the firewall. Screw the engine to the

mount with 8-32

x

1" screws to see how it fits.

- 5 1

-