Top Flite TOPA0305 Part 2 User Manual

Page 24

SHEET THE BOTTOM

OF

THE WING CENTER SECTION

1. Install your servo extension cords,

"Y"

connectors and air lines

if

you are installing

retracts. The servo extension cords don't have to

be connected to the servos and the air lines don't

have to be connected to the retracts but they

should be installed

so

you can finish the sheeting.

Plan this carefully. Be certain you have connected

both aileron extension cords into the same "Y"

connector and both flap extension cords into the

same "Y" connector. Give yourself plenty of slack

on the wires and air lines

so

you will be able

connect everything after you cover your model.

2. Sheet the bottom of the wing center section

with two 3/32"

x

3"

x 30" balsa sheets and leftover

3/32" balsa if needed. Before you glue the sheet

that goes over the wing bolts, first cut two 1 "

lengths from the 9/16" diameter

x 8" cardboard

tube. Glue that sheet in position with the cardboard

tubes. Glue the cardboard tubes to the sheeting

and wing bolt plates. After the glue dries, cut and

sand the tubes flush with the sheeting.

Hint: Temporarily fit the flaps to the wing and cut

the ends of the bottom aft sheet to provide the

correct spacing at the ends of the flaps.

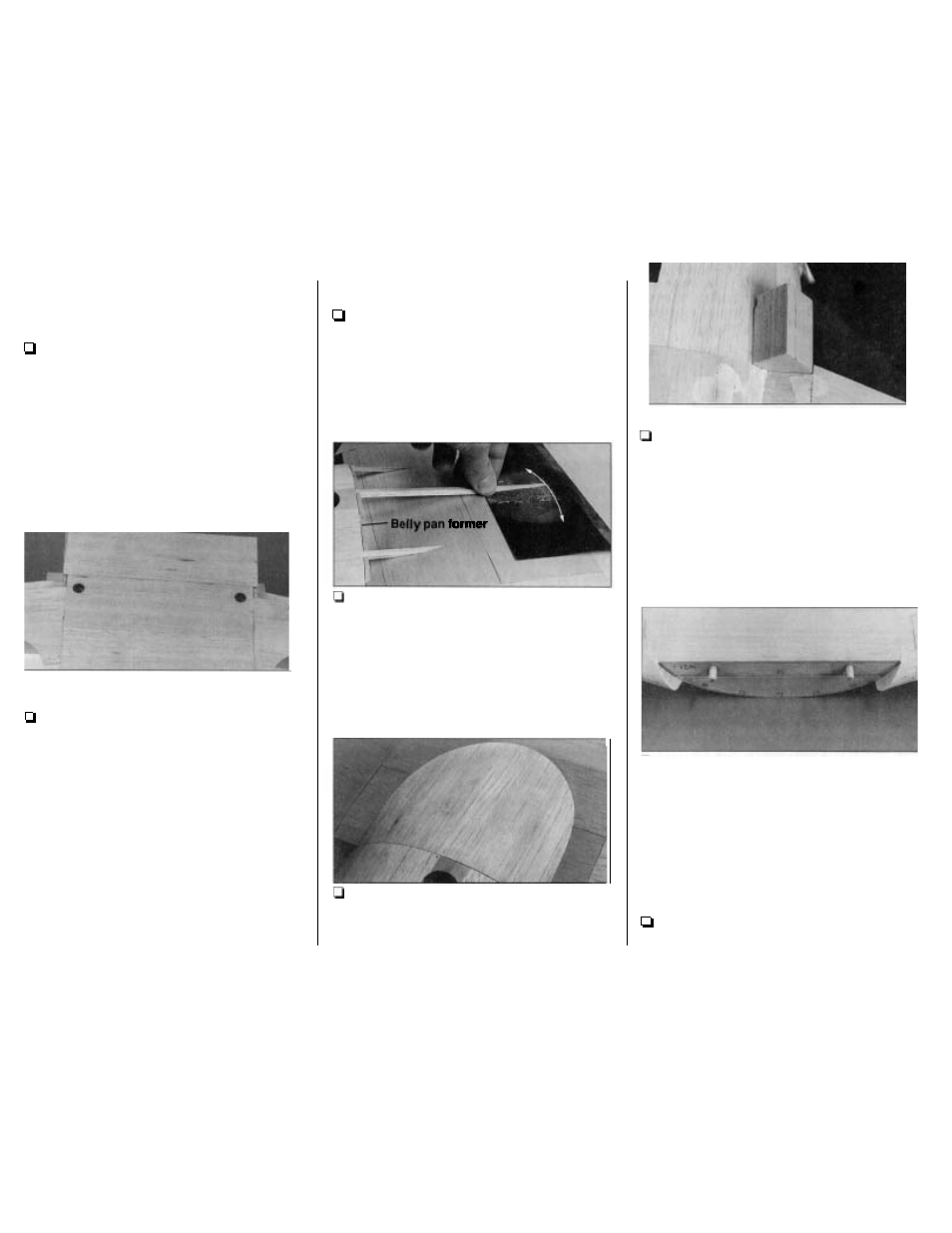

MAKE THE BELLY PAN

1. Bolt the wing

to

the fuselage. Place the die-

cut 1/8" plywood belly pan former F2W on the

front of the wing

so

it is resting against fuse former

F2. Trim the bottom of F2W

so

it sits 3/32" below

the bottom fuselage sheeting (to accommodate the

belly pan sheeting). Carefully glue

F2W to only

the wing.

pan

2. From a 3/16" x 3/16" x 30" balsa stick, cut one

6-1/2" piece, two 4-3/4" pieces and two 2-1/4"

pieces to make the belly pan stringers. Sand one

end of the stringers

so

they conform to the shape

of the bottom of the wing. Glue them in position.

Hint: Place a piece of sandpaper on the bottom of

the wing and move the stringers back and forth,

sanding them to the correct shape.

3. Sheet the belly pan with leftover 3/32" balsa

sheeting. Feather the edges with lightweight hobby

filler. After the filler dries, remove the wing and

sand the belly pan to blend with the fuse.

-

60

-

4. With the wing off the fuse, sand one of the 1"

x 1-3/4" x 2" wing fairing blocks to match the

curvature of the right side of the fuse at the leading

edge of the wing. Bolt the wing to the fuse. Sand

the side and rear of the wing fairing block

so

it fits

between the wing and the fuse as shown in

the photo. Glue the wing fairing block to the

wing only.

5. Remove the wing and sand the wing fairing

block to match the shape of the top of the wing.

The fairing block extends below the bottom

sheeting,

so

blend it to the belly pan and the

bottom of the wing with filler. Shape and fit the

other fairing block the same way.

6. Use lightweight hobby filler to blend the belly

pan to the wing and sand it smooth after it dries.