Warning – Reznor R6GP Unit Installation Manual User Manual

Page 6

6

COMBUSTION AIR & VENTING

WARNING:

Installation methods other than those described

in the following sections must comply with the

National Fuel Gas Code and all applicable local

codes for providing sufficient combustion air

to the furnace.

Provisions must be made during the installation of this

unit that provide an adequate supply of air for combustion.

• Instructions for determining the adequacy of an

installation can be found in the current revision of the

NFGC (ANSI Z223.1 / NFPA54).

Consult local codes

for special requirements

. These requirements are for

US installations as found in the NFGC.

• The requirements in Canada (B149.1) are structured

differently. Consult with B149.1 and local code officials

for Canadian installations.

WARNING:

Combustion air must not be drawn from a

contaminated atmosphere. Excessive exposure

to contaminated combustion air will result in

safety and performance related problems.

To maximize heat exchanger life, the combustion air

must be free of chemicals that can form corrosive acidic

compounds in the combustion gases. The recommended

source of combustion air is to use clean air from outside.

DO NOT place any chemicals with flammable or caustic

vapors or these other corrosive chemicals near the

vent termination:

• Gasoline/Kerosene

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents

• Cements, glues, paint removers, varnishes, etc.

• Hydrochloric acid

• Masonry acid washing materials

• Plumbing Stack

Air openings in the door of the unit, warm air registers, and

return air grilles must never be restricted. If the unit does

not receive an adequate supply of air for combustion, the

flame roll-out control located above the burners will open,

turning off the gas supply to the burners. This safety device

is a manually reset switch. IMPORTANT NOTE: DO NOT

install jumper wires across this control to defeat its

function or reset the control without identifying and

correcting the fault condition.

If this control must be replaced, use only factory authorized

replacement parts specified in the Replacement Parts

List provided online.

Vent Termination

This unit has been equipped with an integral venting

system and designed to operate only with this venting

system. If desired, an accessory venting kit is available.

Use only NORDYNE approved venting kit listed in the

technical service literature

.

WARNING:

This unit is intended for outdoor installation

only. Do not vent the unit through a conventional

venting system.

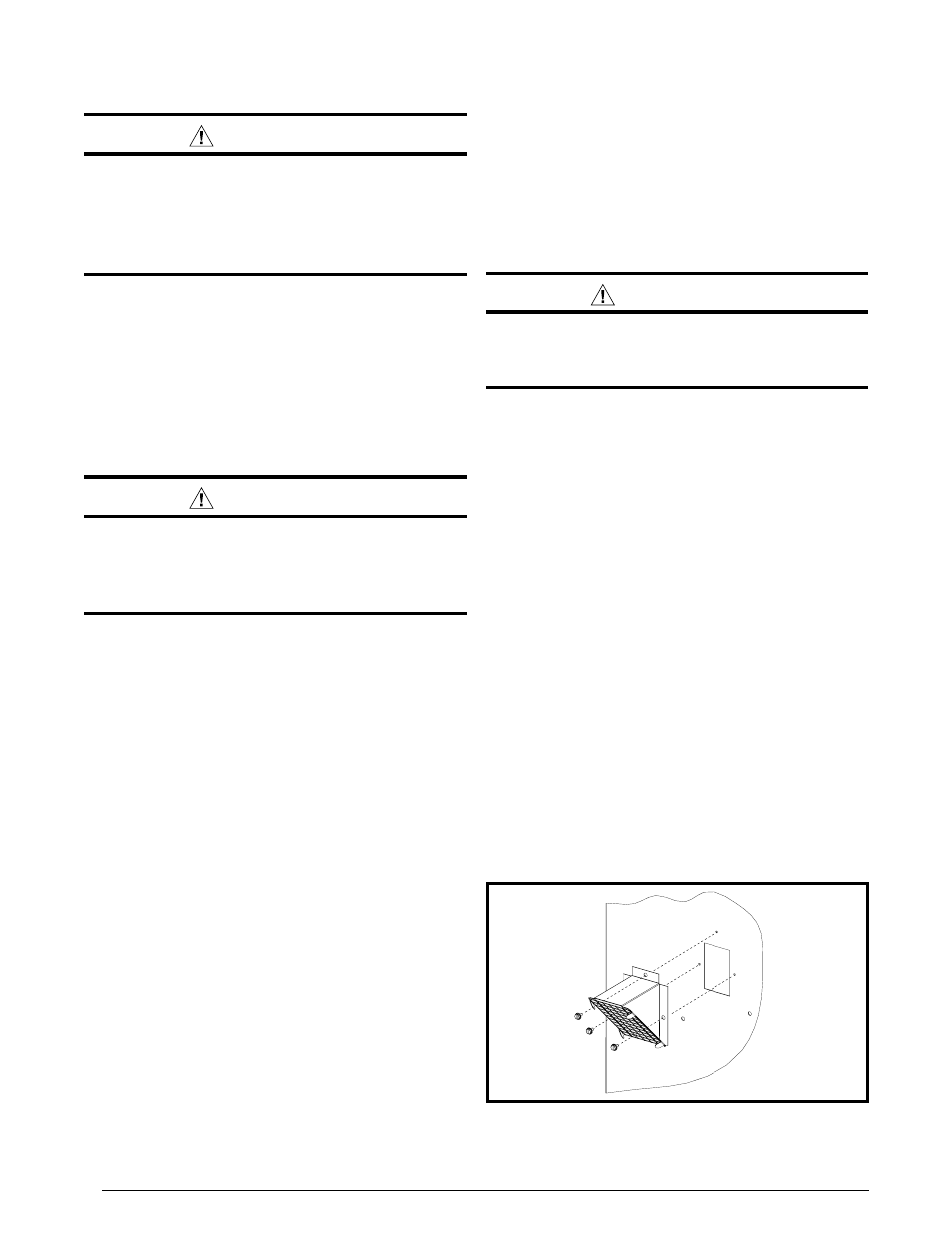

A vent cover assembly has been supplied with the unit

and can be found secured to the gas controls within the

burner area of this unit.

Figure 1 displays the proper

installation of the vent cover assembly over the vent outlet

of the corner panel. The fasteners used to secure the vent

cover assembly have been included on the unit end panel.

The list below summarizes the location requirements for

the venting system termination:

• The location of the vent termination must be consistent

with the National Fuel Gas Code (ANSI Z223.1) or CAN/

CGA-B149 Installation Codes.

• Must be located at least 4 feet horizontally from any

electric meters, gas meters, regulators, and relief

equipment.

• Must be located at least 3 feet above any forced air inlet

located within 10 feet of unit.

• Must be located at least 4 feet below, 4 feet horizontally

from, or 1 foot above any door, window, or gravity air

inlet into any building.

• Must be located at least 1 foot above grade and installed

in such a manner as to prevent snow accumulation from

obstructing the vent termination.

• The vent termination must not be located above any

public walkways.

• The vent cover assembly must be installed to assure

proper operation of the unit.

Figure 1. Vent Cover Assembly