Unbalanced 3-phase supply voltage, Thermostat / low voltage connections, Heat anticipator – Reznor R6GP Unit Installation Manual User Manual

Page 14: Blower speed

14

Example

:

AB = 451V

BC = 460V

AC = 453V

2. Determine the average voltage in the power supply.

3. Determine the maximum deviation:

4. Determine percent of voltage

imbalance by using the results

from steps 2 & 3 in the following

equation.

max voltage deviation

from average voltage

= 100 x

average voltage

% Voltage Imbalance

6

454

100 x

= 1.32%

Example:

1. Measure the line voltages

of your 3-phase power

supply where it enters the

building and at a location

that will only be dedicated

to the unit installation (at

the units circuit protection

or disconnect).

Unbalanced 3-Phase Supply Voltage

Voltage unbalance occurs when the voltages of all phases

of a 3-phase power supply are no longer equal. This

unbalance reduces motor efficiency and performance.

Some underlying causes of voltage unbalance may include:

Lack of symmetry in transmission lines, large single-phase

loads, and unbalanced or overloaded transformers. A

motor should never be operated when a phase imbalance

in supply is greater than 2%. Perform the following steps

to determine the percentage of voltage imbalance:

In this example, the measured line voltages were

451, 460, and 453. The average would be 454 volts

(451 + 460 + 453 = 1,364 / 3 = 454).

The amount of phase imbalance (1.32%) is satisfactory

since the amount is lower than the maximum allowable

2%. Please contact your local electric utility company if

your voltage imbalance is more than 2%.

Example:

From the values given in step 1, the BC voltage (460V)

is the greatest difference in value from the average:

460 - 454 = 6

454 - 451 = 3

454 - 453 = 1

Highest Value

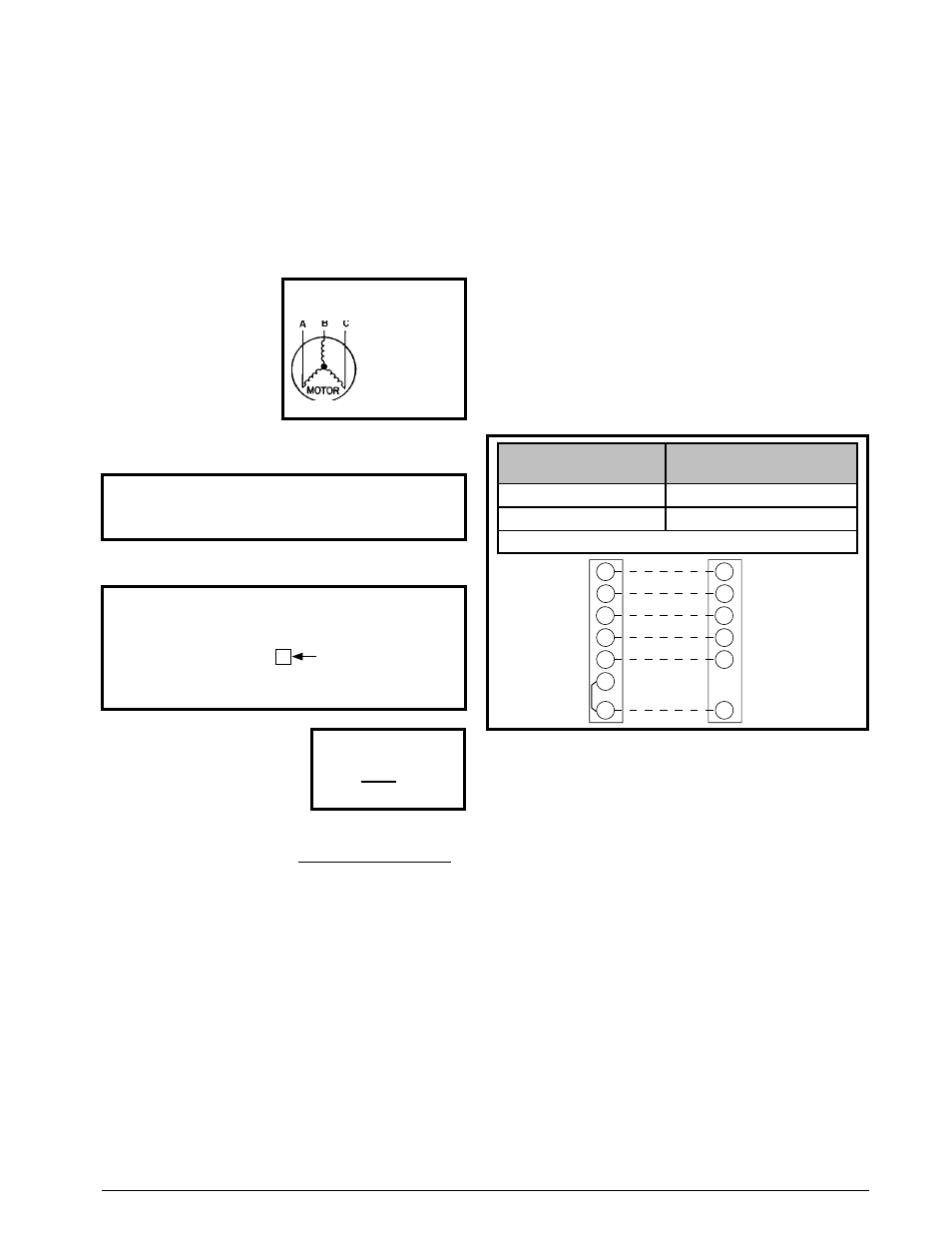

Figure 10. Typical 2 - Stage Heat/Cool

Thermostat Connection

Y1

Y2

W2

W1

G

RH

RC

Y1

Y2

W2

W1

G

R

Indoor

Thermostat

Sub-Base

Unit Low Voltage

Terminal

T-Stat Wire

Gauge

Recommended T-Stat Wire

Length - Ft. (Unit to T-Stat)

18 Ga.

0 - 60

16 Ga.

61 - 130

Field Supplied Wiring - - - - - Use Solid Class II Copper Wire

• A two-stage heating/cooling thermostat is required for

R6GP series units. Select a thermostat which operates

in conjunction with the installed accessories. See Figure

10 for proper wire gauge and their recommended lengths

for typical thermostat connections.

• The low voltage wires must be properly connected

to the units low voltage terminal block. Route 24V

control wires through the gas furnace side of the unit.

Recommended wire gauge and wire lengths for typical

thermostat connections are shown in Figure 10.

• The thermostat should be mounted about 5 feet above

the floor on an inside wall. DO NOT install the thermostat

on an outside wall or any other location where its

operation may be adversely affected by radiant heat from

fireplaces, sunlight, or lighting fixtures, and convective

heat from warm air registers or electrical appliances.

Refer to the thermostat manufacturer’s instruction sheet

for detailed mounting information.

Thermostat / Low Voltage Connections

• Single Package Gas Heating / Electric Cooling Rooftop

Units are designed to operate with a 24 VAC Class II

control circuit. The control circuit wiring must comply

with the current provisions of the NEC (ANSI/NFPA

70) and with applicable local codes having jurisdiction.

Thermostat connections should be made in accordance

with the instructions supplied with the thermostat.

Heat Anticipator

Verify if the thermostat being used for the installation has a

heat anticipator setting. This function allows the thermostat

to anticipate the space heating rate and time the burner

to shutoff accordingly. Always refer to the thermostat

manufacturers instructions for the correct settings.

Blower Speed

The blower speed is preset at the factory but must

be verified at each installation. For optimum system

performance and comfort, it may be necessary to change

the factory set speed. Refer to Blower Performance Data

(Tables 5 - 12, pages 29 - 36) for proper operating range.

Always ensure drive belt is secure and tensioned properly.

Also inspect variable pitch sheaves for proper tightness

of the set screws