Notice, Fuel system – step 5 – Proheat X45–School Bus User Manual

Page 69

PROHEAT INSTALLATION & SERVICE

5-12

NOTICE

Fuel Nozzle parts are a matched set

and not interchangeable.

NOTICE

DO NOT use a tip cleaner in the fuel

orifice

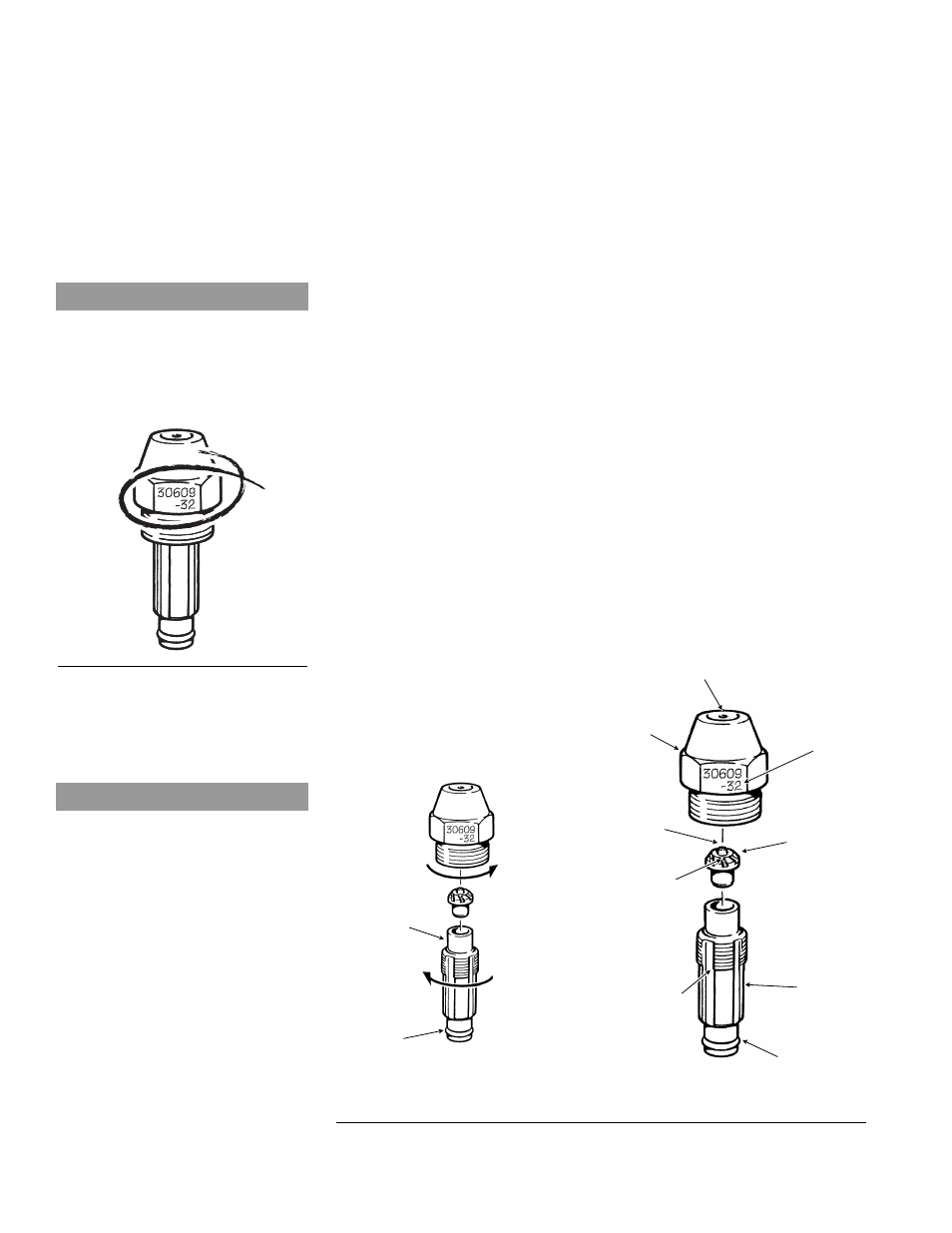

Fuel System – Step 5

Check:

Nozzle

a)

For fuel nozzle and o-ring damage and/or contamination.

Test Procedure — Fuel Nozzle Removal, Inspection & cleaning or replacement:

a)

Remove three (3) bolts from the fan end and open up heater.

b)

Remove nozzle from fan end.

c)

Disassemble, inspect, clean and reassemble Fuel Nozzle

(Figure 5-12).

Fuel Nozzle disassembly, inspection, cleaning & reassembly:

• Hold the Fuel Nozzle stem lightly but firmly in a vise using

soft jaws, take care not to cause damage. Disassembles

in three pieces.

• Inspect Fuel Nozzle stem and O-ring for contamination and/or

damage. Inspect and clean distributor fuel orifice (a soft

bristled brush may be used), air passages, head and stem

with electrical contact cleaner or warm soapy water.

• Re-clamp the Fuel Nozzle stem lightly but firmly in a vise

using soft jaws, take care not to cause damage. Reinstall

the distributor and Fuel Nozzle head. Ensure that the

distributor is seated correctly. The Fuel Nozzle assembly is

self-aligning. Torque to 30±3 in/lbs (3.4±0.3 Nm).

d) Inspect the Fuel Nozzle cavity and clean as necessary using

electrical contact cleaner or warm soapy water

e) Reinstall Fuel Nozzle into the fan end using diesel fuel to

lubricate the o-ring. Torque to 150±10 in/lbs (17±1.1 Nm).

f)

Reinstall fan end and torque three (3) bolts to 75±5 in/lbs

(8.5±0.5 Nm)

Figure 5-11. Nozzle Number Location

FUEL NOZZLE

ORIFICE

AIR PASSAGES

AIR PASSAGES

FUEL AND AIR OUTLET ORIFICE

HEAD

DISTRIBUTOR

STEM

O-RING

NOZZLE

NUMBER

TORQUE = SEE

SECTION 1.3

LUBRICATE

O-RING WITH

DIESEL FUEL

HOLD UPRIGHT

TO ASSEMBLE

ARROWS

SHOW HOW TO

LOOSEN THE

NOZZLE

Figure 5-12

Fuel Nozzle Assembly