Proheat X45–School Bus User Manual

Page 52

4-3

SECTION 4. PRINCIPLE OF OPERATION

Figure 4-3

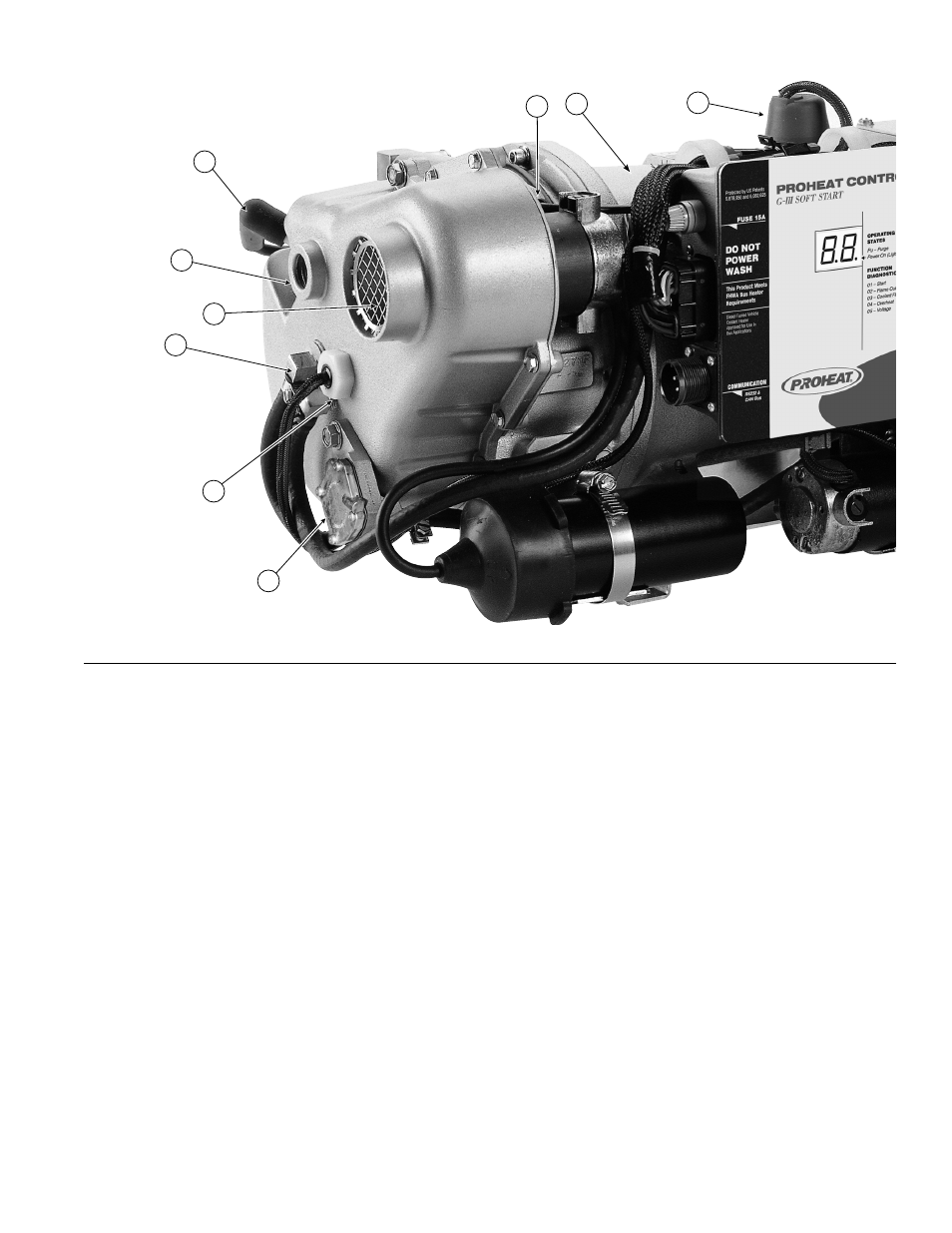

An air/fuel aspirating type spray nozzle (located inside housing). The

compressed air flows through the nozzle at high speed creating a venturi

effect. This siphons fuel from the regulator and combines it with the air,

creating an extremely fine mist which is sprayed out of the nozzle into the

combustion chamber.

Uses an impeller-type fan to supply the combustion air at low pressure. It

is also used to cool and Cool Down (Purge) the combustion chamber

during the 3 minute shut-down sequence.

Allows visual inspection of the combustion process and is invaluable for

reducing time spent on troubleshooting and servicing the heater.

A two-part cast aluminum housing. Coolant will typically rise 10˚ to 15˚F

(6˚ to 8˚C) in temperature as it passes through the heat exchanger,

depending on the flow rate.

9. Inspection Port

10. Heat Exchanger

8. Blower

7. Nozzle

11

10

13

7

9

14

2

12

8