Appendix a - software control functions – LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 75

Page 71

N

eo

T

herm

Boilers and Water heaters

Appendix A -

SOFTWARE CONTROL FUNCTIONS

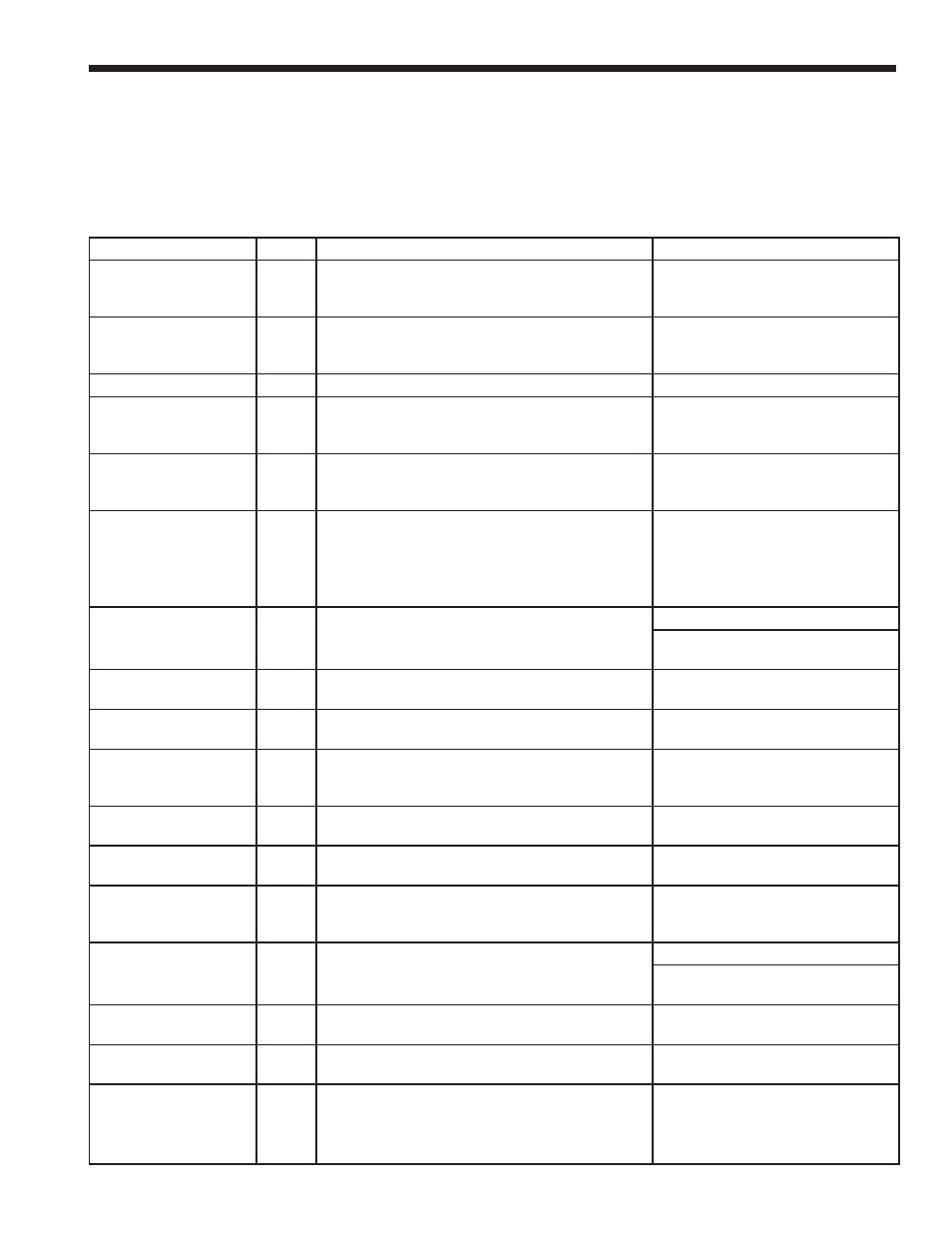

This table includes a listing of all of the control functions that can be used by the operator or installer. Functions that

require a password are indicated in the second column.

Name

PW?

Function

How to get there

Adjustable high limit

Y

The absolute high limit for the water outlet is pre-set

at the factory. If desired, you can set a lower value

here.

quick Start

Adjustable stack limit

Y

The absolute high limit for the stack temperature

is pre-set at the factory. If desired, you can set a

lower value here.

quick Start

Alert log

-

This displays the 15 most recent alerts.

Info/ Diagnostics/ History

Analog sensors

-

This shows the current condition of selected

sensors – temperatures, fan speed, flame signal,

etc.

Info/ Diagnostics

Anti short-cycle time

-

This feature can be set to prevent the burner from

firing and then shutting off quickly in response to a

call for heat that changes state quickly.

Info/ Advanced Setup/ System

Config./ System Config.

Base load common rate

(LL)

-

When using the Lead/ Lag system to control

multiple boilers –

As the heating load increases, this value sets the

point where the controller will fire the next boiler.

See the section on “About Lead/ Lag.”

Info/ Advanced Setup/ Lead Lag

Configuration/ LL Master Config.

Boiler pump control

Y

The boiler pump can be turned on manually, or it

can be set to operate automatically.

Info/ Test/ Manual Pump Operation

Info/ Advanced Setup/ System

Config./ Pump Config.

Boiler pump cycle count Y

A new value can be written here if the pump or

controller is replaced.

Info/ Advanced Setup/ System

Config./ Statistics Config.

Boiler pump overrun

time

Y

This indicates how long the boiler pump will remain

on after demand from any source ends.

Info/ Advanced Setup/ System

Config./ Pump Config.

Burner cycle count

Y

This is incremented on each entry to Run. A new

value can be written here if the burner or controller

is replaced.

Info/ Advanced Setup/ System

Config./ Statistics Config.

Burner name

Y

This parameter allows the installer to give each

boiler unit a unique name.

Info/ Advanced Setup/ System

Config./ System ID and Access

Burner off inhibit time

Y

Set to “No Value.”

Info/ Advanced Setup/ System

Config./ System Config.

Burner run time

Y

This measures the time spent in the Run state.

A new value can be written here if the burner or

controller is replaced.

Info/ Advanced Setup/ System

Config./ Statistics Config.

CH setpoint

-

This setpoint is used to control the hydronic (Central

Heat) function.

quick Start

Info/ Advanced Setup/ CH

Configuration

D gain (CH)

Y

This gain is applied to the Differential term of the

PID equation for the CH loop.

Info/ Advanced Setup/ CH

Configuration

D gain (DHW)

Y

This gain is applied to the Differential term of the

PID equation for the DHW loop.

Info/ Advanced Setup/ DHW

Configuration

D gain (LL)

Y

When using the Lead/ Lag system to control

multiple boilers –

This gain is applied to the Differential term of the

PID equation for the hydronic heating loop.

Info/ Advanced Setup/ Lead Lag

Configuration/ LL Master Config.