Lead / lag operation, 3 or 4 boilers – LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 48

Page 44

LAARS Heating Systems

Caution

You should set the Modbus addresses before you

connect the Modbus wiring. If the wiring is attached

before the Modbus addresses on the controls are

changed, there will be multiple controls with the

same address, and the system will not work.

WARNING

If the Modbus addresses are not assigned properly,

the system could fail to operate correctly, or it might

operate in an unsafe manner. This could lead to

property damage, personal injury or death.

How to get there: On each boiler: From the “Home” screen,

press “I” to go to “Info/Install.” screen. Choose “Advanced

Setup,” then select “System Configuration”. Then select

“System ID & Access,” and select “MB1 Modbus Address.”

Change it to its new unique Modbus address ( 1-8), then

select “MB2 Modbus Address” and change it to the same

address as the changed “MB1 Modbus Address” DO NOT

CHANGE THE MENU LINE “ModBus Address”. It will

automatically change when you change the “MB1 Modbus

Address”

4. The next job is to identify each boiler as a Lead/Lag

Master or Slave.

• On the boiler that will be used as the Lead/Lag Master,

identify the unit that will operate as the master by turning

on “Master Enable.”

How to get there: From the “Home” screen, press “I” to

go to “Info/Install.” Choose “Advanced Setup,” then go

to “Lead/ Lag Configuration.” Select “Lead Lag Master

Configuration.” On the line for “Master Enable,” select

“Enable.”

• On all of the boilers (including the Lead/Lag Master),

identify each unit as a slave by turning on “Slave Enable.”

How to get there: From the “Home” screen, press “I” to

go to “Info/Install.” Choose “Advanced Setup,” then go

to “Lead/ Lag Configuration”. Select “Lead Lag Slave

Configuration.” On the line for “Slave Enable” select

“Enable.” When you select Slave Enable these options will

be displayed

“Enable via Modbus Master” or

“Enable via Sola Master”.

Choose “Enable via Sola Master”.

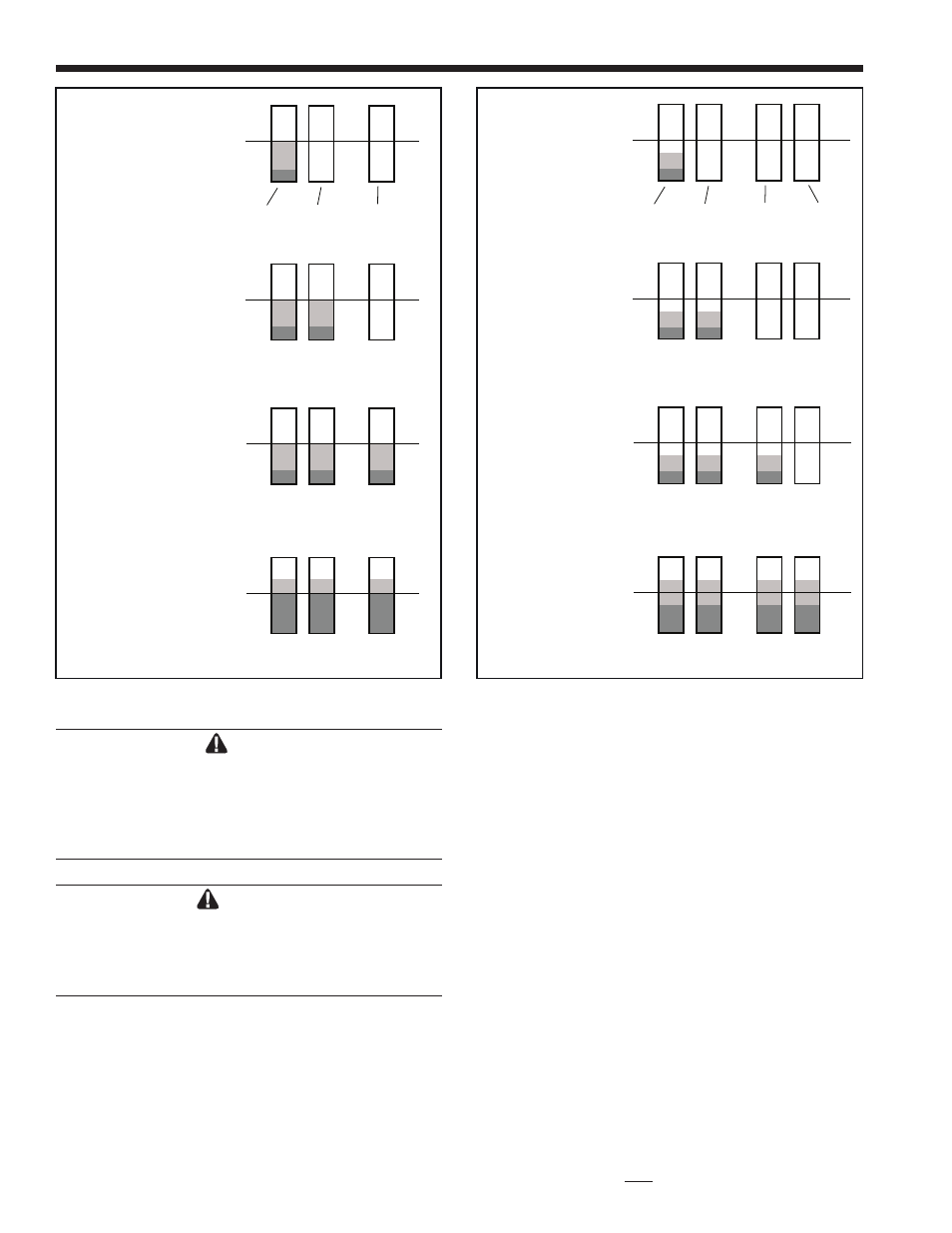

Fig. 39B - Lead / Lag Operation, 3 boilers.

Fig. 39C - Lead / Lag Operation, 4 or more boilers.

Low demand -

The first boiler in

sequence fires at

less than 35%

First

boiler

Second

boiler

Third

boiler

Fourth

boiler

Demand increases -

Once the first boiler

reaches 35%,

the second boiler

switches on, and

both modulate

together between 20%

and 35%

Demand increases -

Once the first two

boilers reach 35%,

the third boiler

switches on, and all

three modulate together

between 20% and 35%

Nearing max. demand -

The fourth boiler is

active. Once all four

reach 35%, all are

allowed to go over

35%

* - The Lead/Lag controller will change the firing order of the boilers,

based on the run time of each burner.

Low demand -

The first boiler in

sequence fires at

less than 50%

First

boiler

Second

boiler

Third

boiler

Demand increases -

Once the first boiler

reaches 50%,

the second boiler

switches on, and

both modulate

together between 20%

and 50%

Demand increases -

Once the first two

boilers reach 50%,

the third boiler

switches on, and all

three modulate together

between 20% and 50%

Nearing max. demand -

Once all three reach

50%, then all three

are allowed to go over

50%

* - The Lead/Lag controller will change the firing order of the boilers,

based on the run time of each burner.