Lead/lag” operation in a system, base load values – LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 47

Page 43

N

eo

T

herm

Boilers and Water heaters

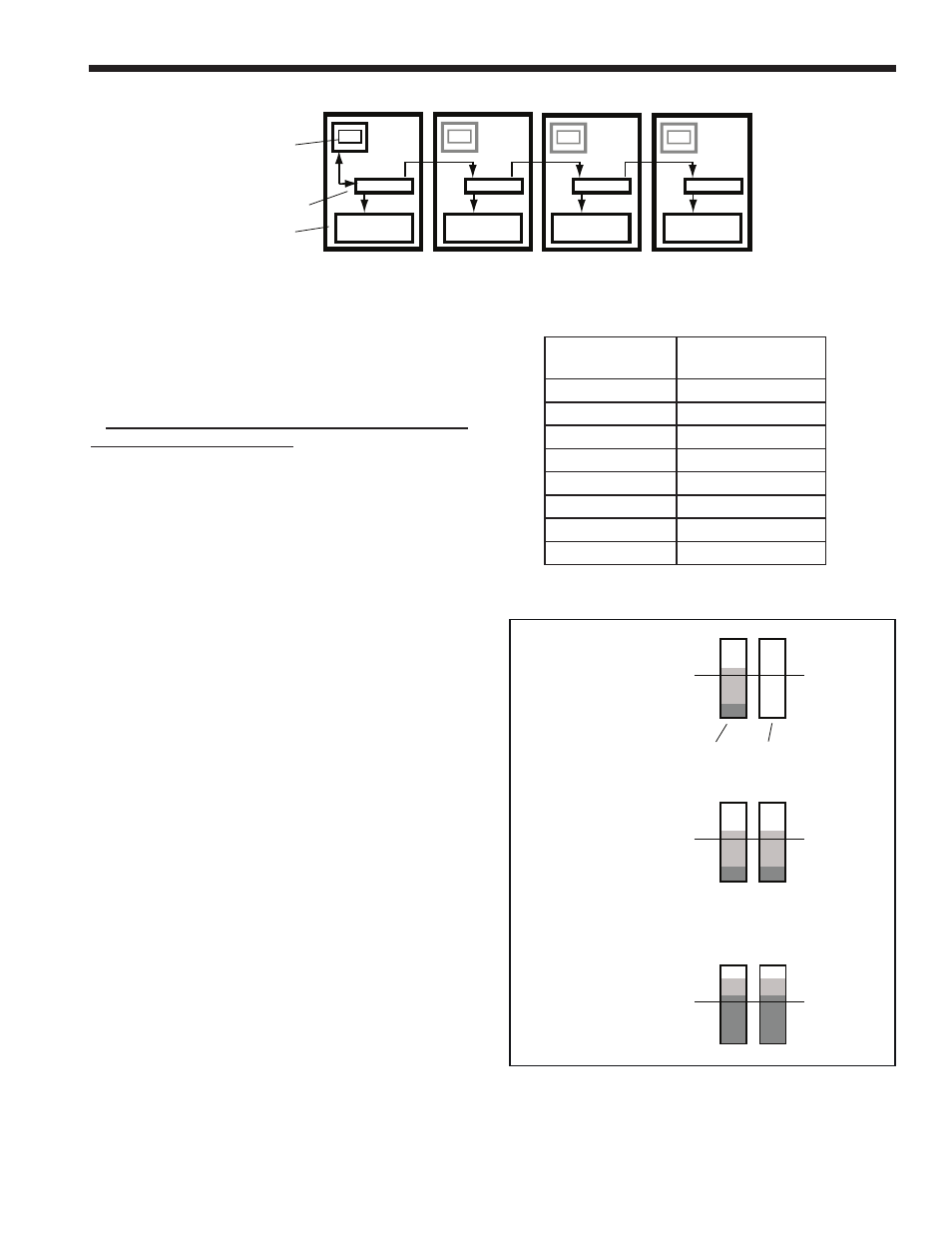

Notice that, when a boiler is operating as part of a Lead/Lag

system, it does not use the normal CH setpoint – it uses the

special LL CH setpoint on the Lead/Lag Master.

The unit acting as the Lead/Lag Master decides which

boiler is assigned to start first. This assignment is rotated

across all of the available boilers so that any one boiler

does not run significantly longer than the others. The

Lead/Lag controller tracks the run times for all of the

boilers, and uses this to calculate the starting order for

the boilers. This means that each time the system starts

up, a different boiler may start first.

• When the Run sequence is initiated, the boiler with the

least amount of runtime will fire.

• If the heating demand increases so that the firing rate

of that first boiler rises to your boiler configurations

Base Load Value (see Table 14), the next boiler in the

sequence will start up and begin firing at 20 to 35% fan

speed (depending on your configuration). After this, the

entire configuration of boilers will modulate up or down

together, in reaction to the changes in demand.

See Figures 39A, 39B, and 39C.

Control Settings for Lead/Lag System - Part 1

1. Power up all of the boilers in the system.

2. In an installation with several boilers, you can give each

boiler a different name. On each unit, go to the screen for

“System ID and Access,” and enter a unique name.

How to get there: From the “Home” screen, press “I” to

go to “Info/Install” Choose “Advanced Setup,” then go

to “System Configuration,” then “System ID and Access,”

and select “Boiler Name.”

3. The controller in each of the boilers needs a unique

“Modbus address” so the Lead/Lag Master can

communicate with it. All of the units come from the

factory with a Modbus address of “1,” so you will need to

change some of these addresses. The unit operating as the

Lead/Lag Master should have address “1,” and the other

boilers should each have unique Modbus address numbers.

Display

Boiler 1

Boiler 2

Boiler 3

Boiler 4

Controller

Burner

Fig. 38 – “Lead/Lag” Operation in a System with Four Boilers. Note - the Displays on Boilers 2 thru 4 will

display information pertaining only to that specific boiler.

Number of boilers

installed

Base load value

1

NA

2

65%

3

50%

4

35%

5

35%

6

35%

7

35%

8

35%

Table 14 - Base Load Settings

Fig. 39A - Lead / Lag Operation, 2 boilers.

Low demand -

The first boiler in

sequence fires at

less than 65%

First

boiler

Second

boiler

Demand increases -

Once the first boiler

reaches 65%,

the second boiler

switches on, and

both modulate

together between 20%

and 65%

Nearing max. demand -

Once both reach 65%,

then they are both

allowed to go over

65%