8c.10 optional field connections, 8c.11 connections to abuilding automation system, 8c.11 connections to a building automation system – LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 50

Page 46

LAARS Heating Systems

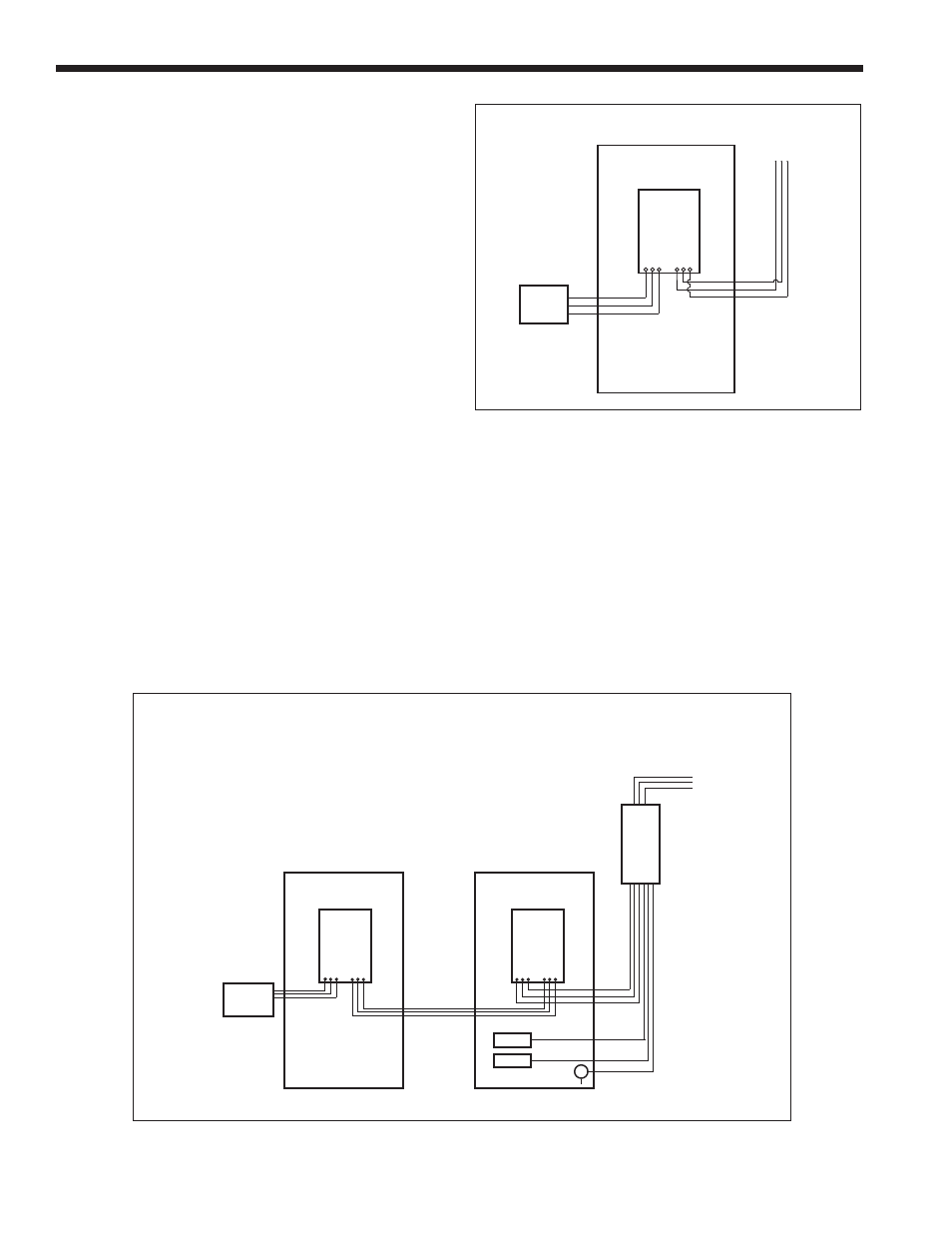

8C.10 Optional Field Connections

Terminal block 8 (TB8) in the control panel can be used for

connecting optional components, such as low water cutoffs,

flow switches, additional high limits and other field-supplied

devices that must be interlocked with the boiler. These are

non-powered dry contacts only. All safeties or end switches

must be wired in series by removing the supplied jumpers.

8C.11 Connections to a

Building Automation System

NeoTherm boilers can be controlled and monitored

through the included Modbus ports. The Modbus wiring

should be completed according to the diagrams shown

below. If alternate communication protocols are desired,

Laars offers “gateways” to allow BACnet, LON, and other

communications protocols. For additional information on

setting up Modbus and other communication protocols,

contact the factory.

Signals from a Building Automation System can be connected

to the MB2 Modbus connections on the controller. See Fig.

41. (MB1 is used to connect to the Operator Interface (UI).

If multiple boilers are connecting in a cascading Lead/ Lag

arrangement, the signals from the Building Automation

System must be brought in through a System Display.

See Fig. 42.

Fig. 41 - BAS Connections to a Single Boiler

Fig. 42 - BAS Connections to a Lead/ Lag System

Operator

interface

(HMI)

Boiler

Controller

MB1 MB2

Customer

communication

(RS-485)

Lead or

master

boiler

Controller

Controller

Master

System

display

TB3 - 24VAC

TB4 - NEU

Operator

interface

(HMI)

Customer

communication

(RS-485)

MB1

MB1

MB2

MB2

Second or

slave

boiler

Com1

Com2