LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 49

Page 45

N

eo

T

herm

Boilers and Water heaters

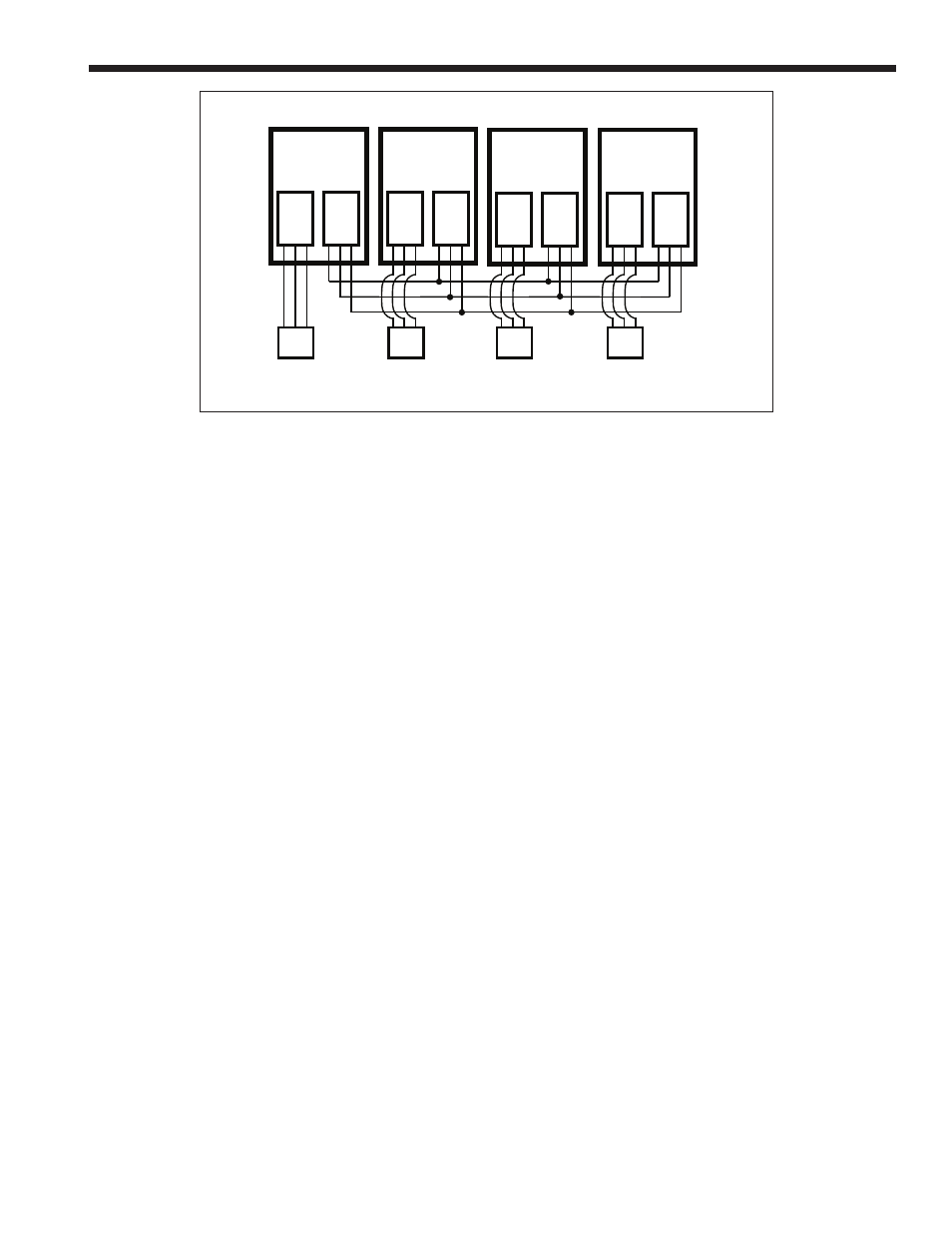

Wiring Connections for Lead/Lag -

Now you can make the Modbus wiring connections

between the units. The controller in each boiler includes

two wiring terminals for the Modbus system, labeled

“MB1” and “MB2.” MB1 has the wiring connections to

the User Interface display on each unit, and MB2 is used

to communicate with the other boilers in the Lead/Lag

system. See Fig. 40.

To reach the controller, open the cabinet of the boiler by

removing the plastic bezel.

The wiring from the controller on the first boiler runs to

the controller on the next boiler. Use 22 AWG or thicker

shielded twisted-pair wire with drain. Two twisted pairs

or three conductors are needed. Wire A on MB2 of Boiler

1 must be connected to A on MB2 of Boiler 2, wire B on

Boiler 1 goes to B on Boiler 2, and wire C on Boiler 1

goes to C on Boiler 2. Repeat this wiring for any other

boilers in the system. Connect all of the drain wires and

ground the drain wire on one end of the assembly only.

Control Settings for Lead/Lag System - Part 2

1. On the Lead/Lag Master, set the setpoint used by the Lead/

Lag system.

How to get there: From the “Home” screen, press “I” to

go to “Info/Install.” Choose “Advanced Setup,” then go

to “Lead/ Lag Configuration.” Select “Lead Lag Master

Configuration,” and go to the line for “Setpoint.”

2. On the Lead/Lag Master, set the Base Load to match

the number of boilers in the system. We mentioned the

Base Load setting in the explanation of the “Lead/Lag

Modulation Cycle.” Whenever the heating demand causes

the active burner(s) to run faster than the Base Load value,

the Lead/Lag system will put an additional burner on line.

The Base Load value depends on the number of boilers in

the system:

Note that you only need to enter the Base Load value on the

Lead/Lag Master.

How to get there: From the “Home” screen, press “I” to

go to “Info/Install.” Choose “Advanced Setup,” then go

to “Lead/ Lag Configuration.” Select “Lead Lag Master

Configuration.” Go to the line for “Base Load Common

Rate.”

8C.9 Hydronic Heating Using External

Modulation Control -

About External Control -

When the NeoTherm is used for hydronic heating with

external modulation control, a call for heat must be supplied

to the “T-T or Interlock” terminal. Once the call is supplied

the control starts the Boiler and System pumps and begins the

ignition process. Once in Run, the NeoTherm monitors the

flame signal, call for heat, safeties, and water temperatures.

The boiler setpoint is used to limit the maximum water

temperature leaving the boiler only. The modulation rate

is controlled by a 4-20mA signal supplied by an external

control. (This can also be 0-10Vdc using a converter - Laars

part number CA006100.) When setting up a system using an

external control, take care to set Anti-Short Cycle feature to

prevent “hunting “ and possible premature component failure.

Connections for External Control -

Connect the 4-20mA signal from an external control or

building automation system to terminal block 7 (TB7) in the

control panel. The connections are labeled Remote Analog

Input. When making the connections, follow the polarity

designations shown on the label.

Figure 40 - Lead-Lag / Cascading Wiring Connections

Boiler 1

Boiler 2

MB 1

Boiler 3

Boiler 4

A B C

A B C

A B C

A B C

A B C

A B C

A B C

A B C

MB 2

MB 1

MB 2

MB 1

MB 2

MB 1

MB 2

User

interface

User

interface

User

interface

User

interface