LAARS NeoTherm NTV (Sizes 150–850 MBTU/h) - Install and Operating Manual User Manual

Page 15

Page 11

N

eo

T

herm

Boilers and Water heaters

All installations should be done following the vent supplier’s

recommended installation techniques. If manufacturer’s

instructions are not available for the material used, follow the

Laars recommendations.

The vent pipe must pitch upward, toward the vent terminal,

not less than 1/4” per foot, so that condensate will run back

to the NeoTherm to drain. Route vent pipe to the heater as

directly as possible. Seal all joints and provide adequate

hangers as required in the venting system manufacturer’s

Installation Instructions. Horizontal portions of the venting

system must be supported to prevent sagging and may not

have any low sections that could trap condensate. The unit

must not support the weight of the vent pipe. Please see Table

2 for proper diameter vs. length allowed.

IMPORTANT NOTE ABOUT COMMON VENTING: A

single vent that is shared by multiple NeoTherm units

MUST be engineered by a competent venting specialist,

and involves the selection of draft inducing equipment,

hardware and controls to properly balance flue gas

pressures.

Do not common vent NeoTherm units

unless the vent system meets this requirement.

NeoTherm units are never permitted to share a vent

with Category I appliances.

Venting Requirements Unique to Canada

NeoTherm boilers and water heaters are Vent Category IV

appliances. Per the requirements of CAN/CSA-B149.1,

only BH vent systems can be connected to these units and

such vent systems, either ULC S636 certified stainless steel

or other ULC S636 certified BH vent (eg. plastics) must be

installed per the vent manufacturer’s certified installation

instructions.

As a result, two items listed in the Unpacking section (Figure

8) are not included with NeoTherm units for Canada

(underlined):

A

exhaust vent terminal (not included)

B.

air intake terminal

C.

temperature/pressure gauge kit

D.

circulator pump/wire harness (units with pump)

E.

CPVC exhaust pipe section (80-500) (not incl.)

F.

outdoor/system sensor kit

G.

flow switch kit (399-850)

H.

alternate size vent/terminal screens

J.

exhaust vent adapter CPVC/ST ST (750-850)

It is the responsibility of the appropriately licensed technician

installing this NeoTherm unit to use ULC S636 certified vent

material consistent with the requirements as described in the

Venting and Combustion Air section.

Class I venting systems are suitable for gas-fired appliances

producing flue gas temperature of more than 135°C, but not

more than 245°C.

Class II venting systems are suitable for gas-fired appliances

producing flue gas temperatures of 135°C or less.

Class II venting systems are further classified into four

temperature ratings as follows:

A

Up to and including 65°C

B

Up to and including 90°C

C

Up to and including 110°C, and

D

Up to and including 135°C

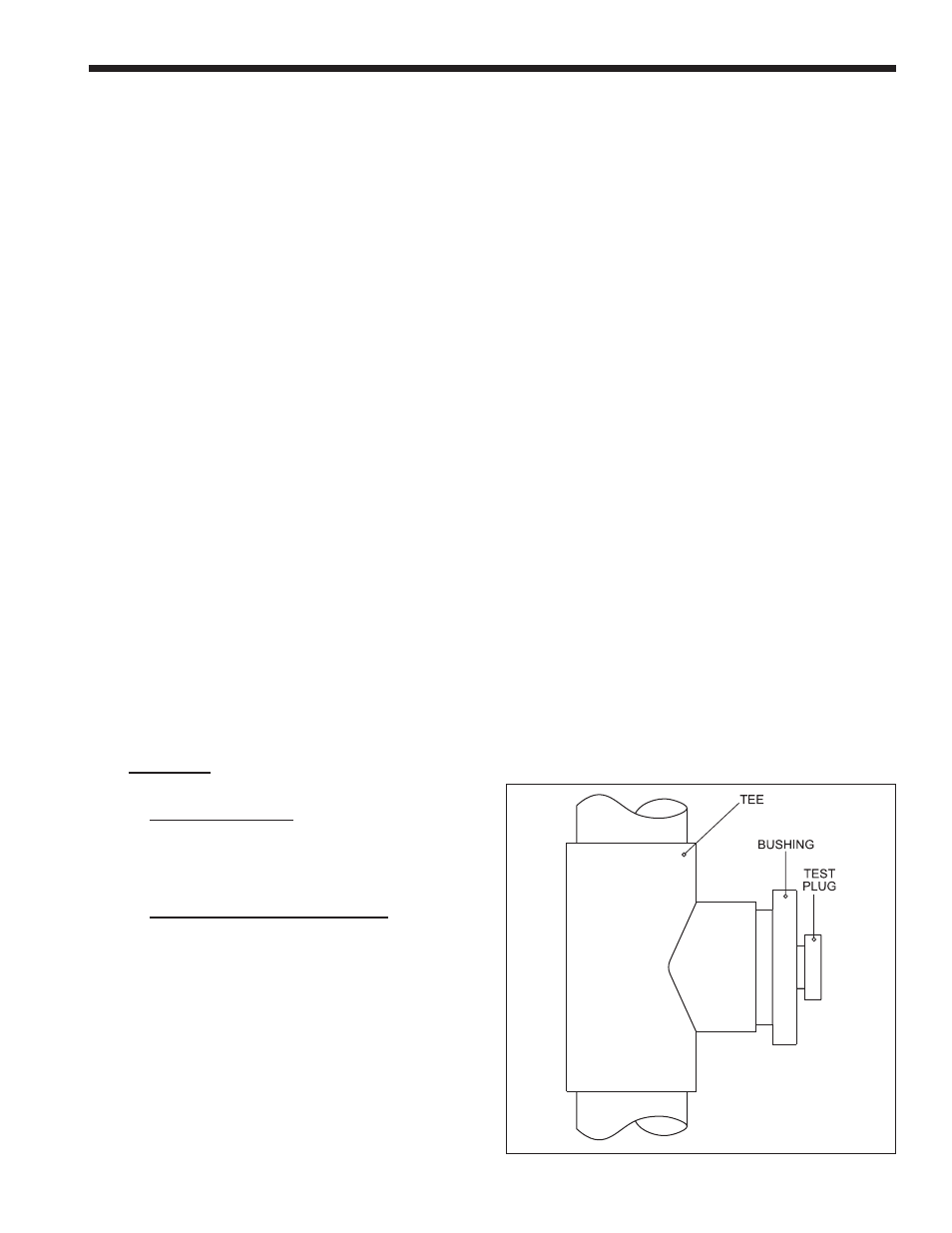

IMPORTANT! It is also the responsibility of the installer

to ensure that a flue gas sampling port is installed in the vent

system. This flue gas sampling port must be installed near the

flue connection of the NeoTherm unit: within 2 feet of the

flue connection. There is no flue gas sampling port internal

to the NeoTherm, so one must be installed in the vent system

external to the NeoTherm unit. A flue gas sampling port

available as a component of the ULC S636 certified vent

system is preferred. However, if one is not available with

the certified vent system, Laars suggests using a tee with the

branch connection sized to allow for insertion of a flue gas

analyzer probe. The branch connection must be resealable

with a cap or other by other means to ensure the vent system

remains sealed. (See Figure 11.)

Consideration must be given to the placement and orientation

of the flue gas sampling port to ensure that condensate is free

to flow back into the NeoTherm unit and not collect anywhere

in the vent system - including in the flue gas sampling port.

An exhaust vent terminal must be installed. If an exhaust vent

terminal is not available with the certified vent system, Laars

suggests the use of a coupler fitting from the certified vent

system into which the vent terminal screen, included with the

Figure 11 - Test Port - ULC-S636 system