Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 45

two servo horns with the arms facing opposite directions as

shown on the plans. Operate the transmitter sticks to make sure

the servo horns turn freely without hitting each other or the fuse

sides. If they do, cut or sand them until they will operate freely.

Turn off the receiver first and then the transmitter.

SKIP THE NEXT STEP IF YOU ARE

NOT INSTALLING SPOILERS

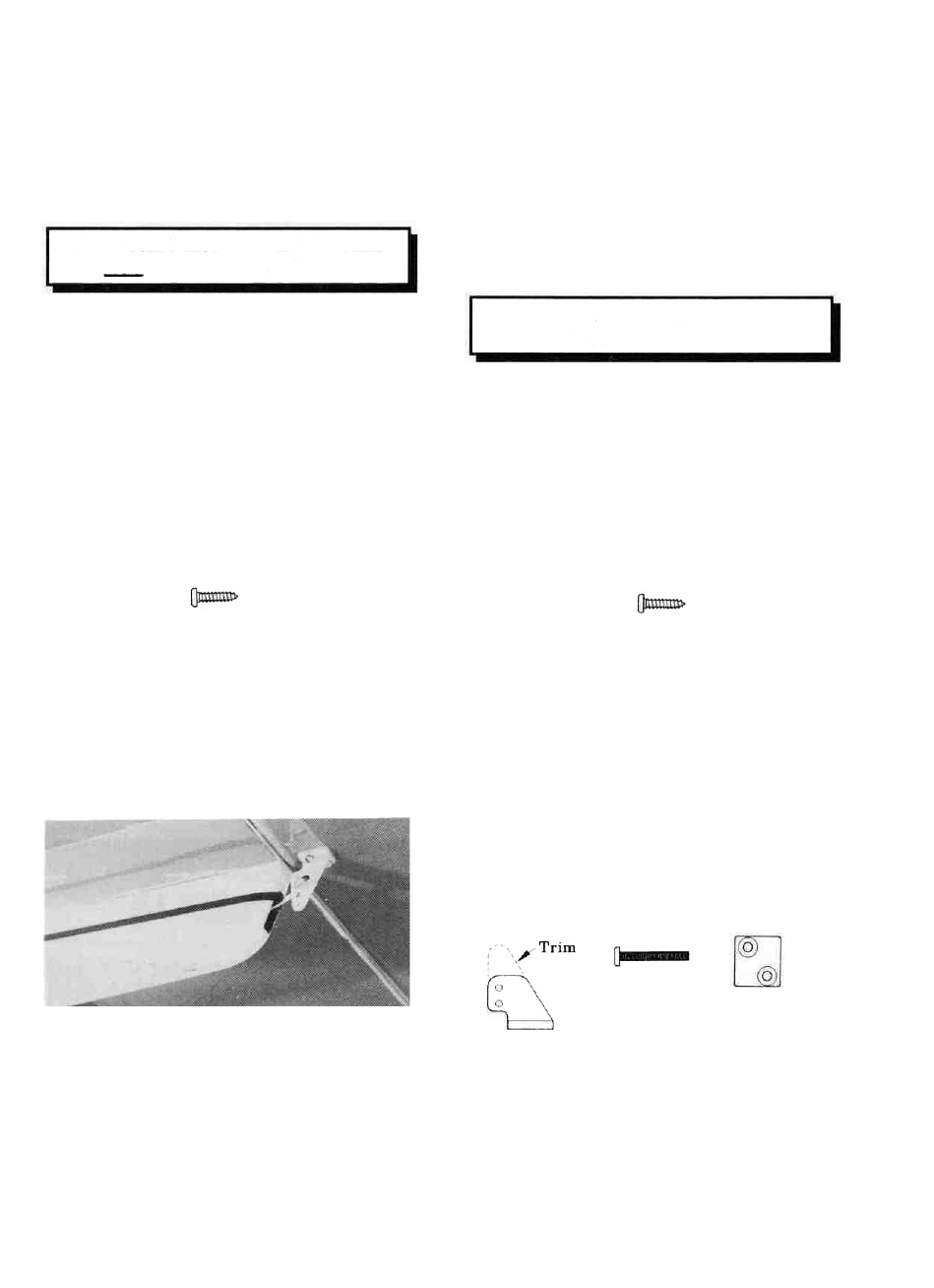

D 6. If you are installing spoilers, mount the spoiler servo

between formers F4 and F5. It can be mounted on servo rails, or

on its side with servo tape. Cut 3 arms off of an X-type servo horn

as you did for the tail surfaces. Insert a #2 x 3/8" Sheet Metal

Screw (SCRW024) in the outside servo horn hole for the spoiler

string. Leave it extending about 1/4" above the horn. Adjust the

servo and your transmitter so the horn is almost pointing towards

the rear of the plane when your transmitter stick is in the "spoilers

closed" position. The horn should rotate towards the front of the

plane when the transmitter stick is moved to the "spoilers open"

position. Which way the transmitter stick moves to open the

spoilers is up to you. Both directions are used by today's pilots.

the pushrod wire where it crosses the hole in the control horn.

Remove the pushrod from the fuse and make a Z-bend in the wire

with the first bend starting where the marks are. Cut any excess

wire off 1/4" past the Z-bend and reinsert the pushrod into the

fuse. Remove the nylon control horn from the elevator and insert

the Z-bend into the second hole from the inside. Re-install the

control horn to the elevator. Adjust the nylon clevises until the

control surfaces are at neutral when the servo horns are perpen-

dicular to the centerline of the fuse. Cut the 2-56 x 5/8" screws

off flush with the nylon nutplates.

SKIP TO STEP 13 IF YOU BUILT

THE SPORT WING!

D 8. Cut all the arms but one off of the three longest servo

horns you can find for your radio (3/4" - 1" radius is needed for

maximum surface throw). Mount the aileron servos on the ply

hatches and install the servo horns so they are rotated approx. 15

- 20 degrees forward when the transmitter stick is at neutral.

Mount the flap servo on its hatch and install the servo horn so it

is rotated approx. 20 - 30 degrees rearward when the transmitter

stick is at the "neutral flap" position. Install the hatches on the

wing with four #2 x 3/8 sheet metal screws each.

NOTE: The following paragraph is written using ordinary

nylon tube type pushrods. They arc intended only as a

guideline to help you install your pushrods, so descriptions

may differ from your particular setup.

D 7. Slide the pushrod inner tubes into the fuse. Snap the nylon

clevises into the outermost hole in the servo horns. The rudder

pushrod goes to the left servo and the elevator pushrod goes to the

right servo. A Z-bend is recommended for the elevator/pushrod

connection. With the elevator and elevator servo in their

neutral position, use a felt tip marker to make a small mark on

D 9. Tack glue the Nylon Control Horns (NYLON03) in

place on the ailerons with a drop of thin CA. They should be

located directly behind but about 3/32" outboard of the servo

horn. Drill two 3/32" holes through each aileron using the control

horns as guides. Remove the control horns and harden the balsa

in the area of the control horns (on both sides of the ailerons) by

poking several holes with a pin, then apply thin CA glue and

allow it to soak in and cure. Wipe off any excess glue before it

cures. Cut off the nylon control horns just above the second hole

as shown in the sketch (if your radio does not have servo endpoint

adjustments wait until you have all the control throws properly set

before doing this). Mount the control horns with the 2-56 x 5/8"

Machine Screws (SCRW002) and the Nylon Nutplates which

were attached to the horns. Cut the screws off flush with the nylon

Nutplates.

D 10. Screw a Nylon Clevis (NYLON17) on two 12" Threaded

Wire Rods (WIRES16) until the threads start to exit the base.

Snap the nylon clevis into the outer hole of the control arm and

make a mark where the rod crosses the outer hole in the servo arm

45