Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 12

the work surface and tightly against the spars. It is important to

do a good job of gluing these in place as they are responsible for

most of the wing's strength. Also glue a shear web to the front of

the spars. Because of the 1/16" bottom sheeting, the front shear

webs will extend above the top spar, but just trim them off after

you have installed all the webs. C-1 and C-2 Clamps (SFT1W22)

can be used to help hold the webs in place while the glue cures.

Install the remaining balsa shear webs. They continue on both the

front and the back of the spar all the way to the last W2S Rib.

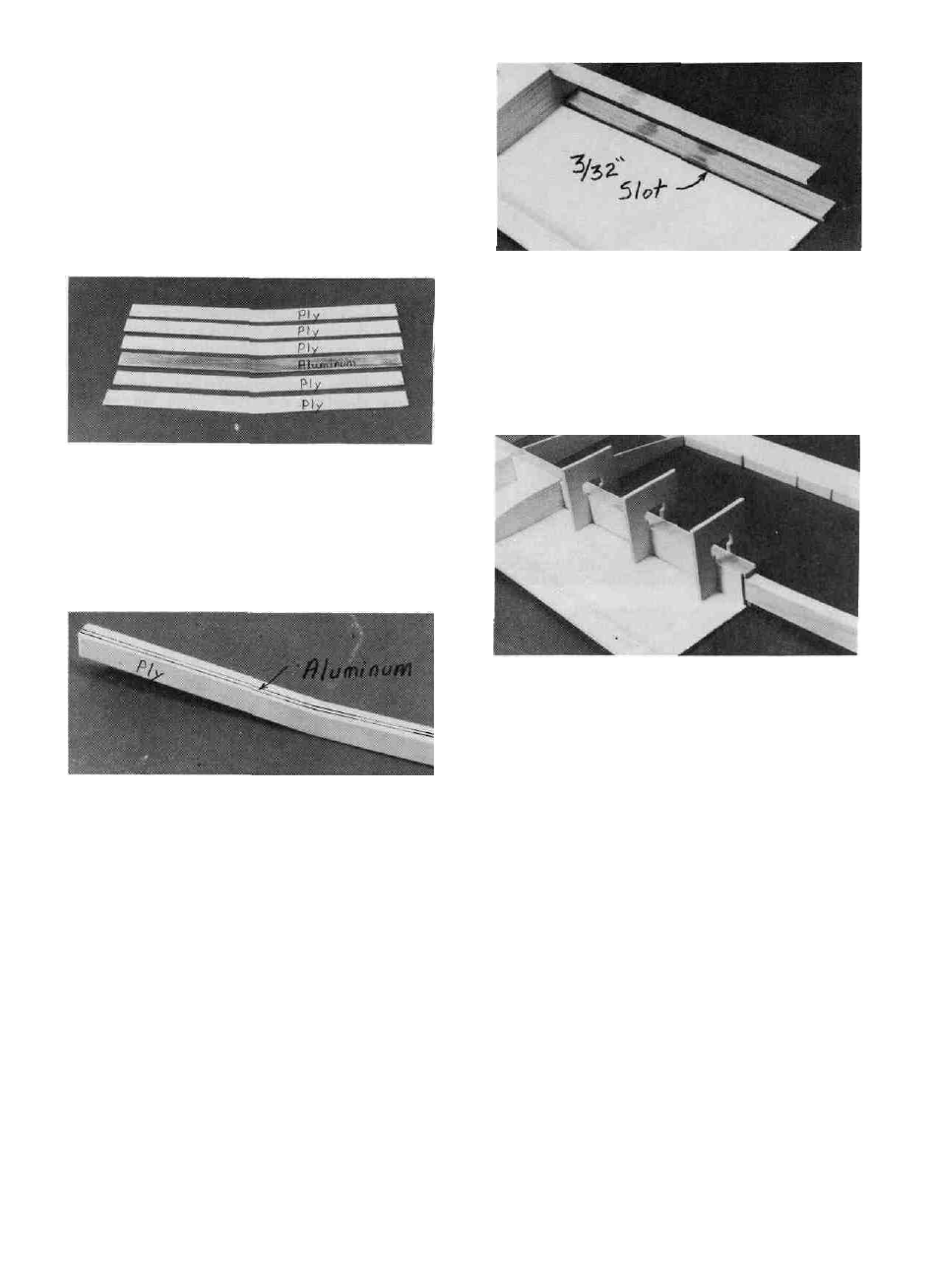

DD 13. Punch out the five 1/16" Ply Wing Joiner Lamina-

tions (SPT1W09) and lightly sand the edges to remove any rough

spots. Locate the 1/16" Aluminum Wing Joiner Blade

(ALUM008). Clean the aluminum joiner with alcohol to remove

any oily residue and sand each side with coarse sandpaper to

scratch the surface and help the glue stick.

I—II—I 14. Use either epoxy or med. or thick CA to glue one of

the 1/16" ply laminations to the 1/16" aluminum blade. Apply as

much pressure (clamps, clothespins, weights, etc.) as possible

while the glue is curing and be sure to accurately line up the two

pieces. Glue two more 1/16" ply laminations to each side of the

now 1/8" thick joiner using the same procedure.

DD 15. Sand the top edge of the laminated joiner flat and

glue the Die-Cut 1/16" Ply Joiner Shim (SPT 1W09) in place on

top of the joiner. Sand the edges of the finished "wing joiner" to

remove any glue globs and to round off the comers.

the panel and mark approximately 1/32" in front of it. Now cut

along this line and the spar to remove a 3/32" wide strip of wood

from the root of the panel to the first W2S rib. Scrape off any glue

or balsa wood thai may still be on the spar with the back edge of

an Xacto knife. IMPORTANT - Be sure to get the edge of the

spar "clean" as a good glue joint between the spar and the joiner

box side is very important.

DD 17. Test fit the joiner box sides in place. One side

should be installed on the front of the spars and the other on the

back. Notice that one end of the side is slanted at a 3-1/2 degree

angle. This end must be at the wing centerline. The "long" edge

of the side should be at the bottom. Use the C1 Clamps

(SPT 1 W22) to hold the sides in place and test tit the wing joiner

into the box formed. This "box" will be referred to as the "joiner

box". The spars should fit snugly down on the wing joiner, but

make sure the joiner is not holding the spars above their normal

position. If it is remove the joiner and sand it until it fits correctly.

DD 18. Remove the clamps and the joiner and apply a bead

of epoxy along the spar edges. Install the joiner box sides and

hold them in place with the C1 clamps. A good glue joint is

important here but be careful not to get any excess glue inside the

box formed by these sides. Insert the joiner into the box and then

remove it a couple of times to scrape any excess glue out of the

box. Wipe any glue off the joiner before it cures.

DD 16. Locale two of the 1/16" Ply Joiner Box Sides

(SPT 1 W 11) that have an "S" embossed on them. Hold one of the

sides in place on the front of the spars at the "root" (inner) end of

DD 19. Sand the edges of the joiner sides to remove any

sharp comers or glue globs. Wrap the entire joiner box with a

strong thread (2 - 4 lb. fishing line works well). The thread should

12