Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 32

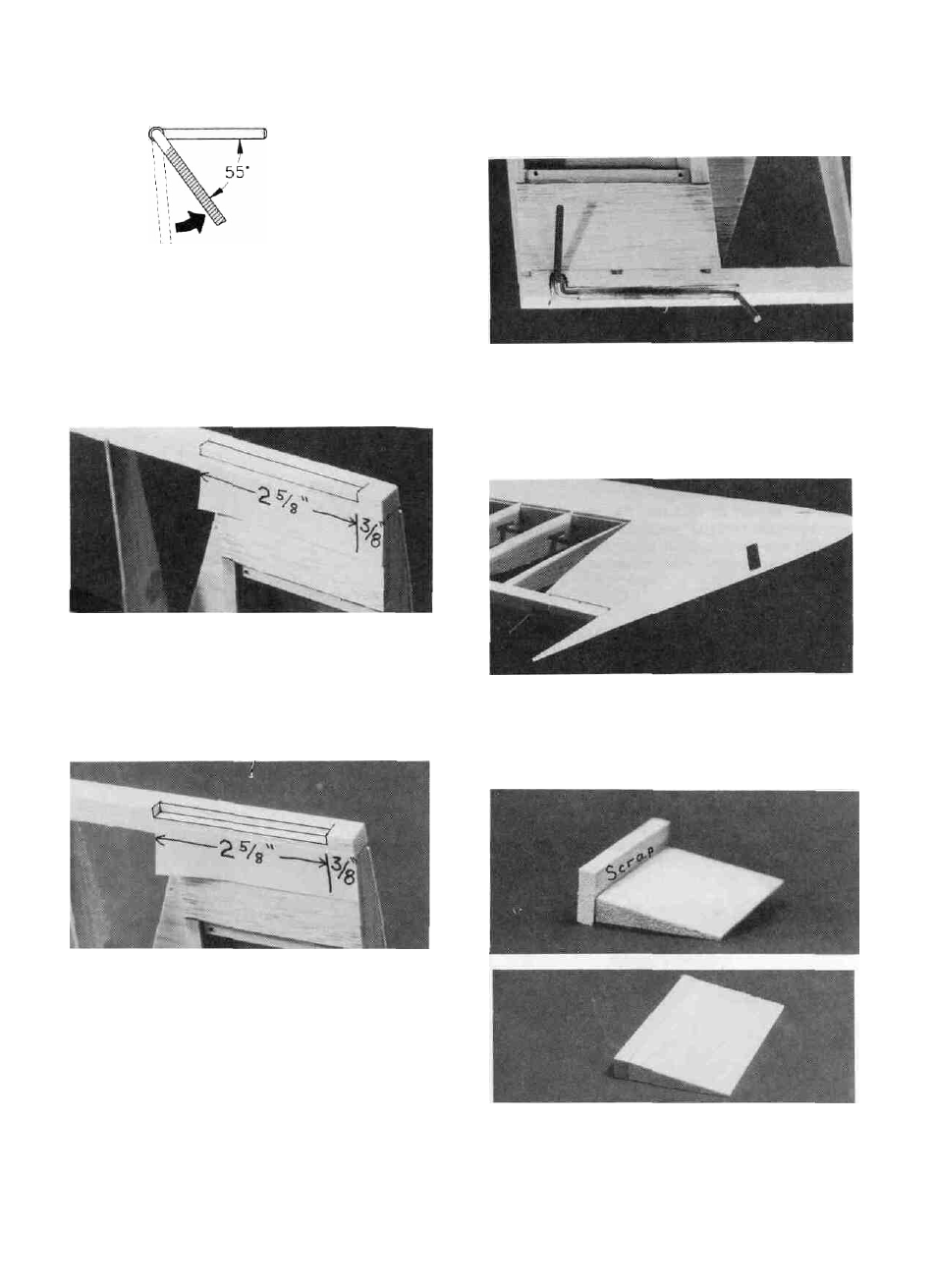

INSTALL FLAP TORQUE RODS

torque rod will exit the bottom Cut a notch in the sub TE to allow

the torque rod to rotate forward

Chamfer end

Twist to here

Original Position

DD 1 Notice there is a "right" and a "left" torque rod Twist

each rod to match the sketch above (to allow the correct flap

movement) Use a small file or very fine sandpaper to de-burr the

very tip of the unthreaded end of each torque rod

D D 2 Starting 3/8 from the root of one wing panel, draw a

line on the back edge of the sub TE is 5/32 away from the

bottom edge of the sub TE and 2-5/8" long Draw a line using the

same procedure on the bottom of the sub TE Both of these lines

should be 5/32 away from the back - bottom edge of the sub TE

D D 3 Cut a 5/32 square strip out of the sub TE using the

lines you just drew Test fit the torque rod into this groove to make

sure the groove is long and deep enough The torque rod nylon

bearing should be flush with both the back and the bottom edge

of the sub TE You can make the slot longer or deeper if needed

to allow the torque rod to operate freely

D D 5 Scuff up the outer surface of the torque rod bearing

with coarse sandpaper Apply a small amount of vaseline around

the ends of the bearing to keep glue from seeping in and glue it

in place Make sure the bearing is centered on the torque rod and

does not extend past the bottom or back surface of the sub TE

DD 6 Glue one of the 1/16" Balsa Root Caps (SPT1W21)

without an "S" to the root of the wing panel It should be aligned

with the sub TE, thc joiner box and the LE as best as possible Due

to building and manufacturing tolerances, it is not unusual for this

root cap to not match the wing shape exactly

D D 4 Make sure you have the correct (right or left) torque

rod with the correct panel and mark on the sub TE where the

DD 7 Cut a piece of 11/32" Balsa Inner TE/Flap (SPT1W15)

2-1/4" long and a scrap piece of 1/4" thick wood 2-1/4" long (from

32