Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 11

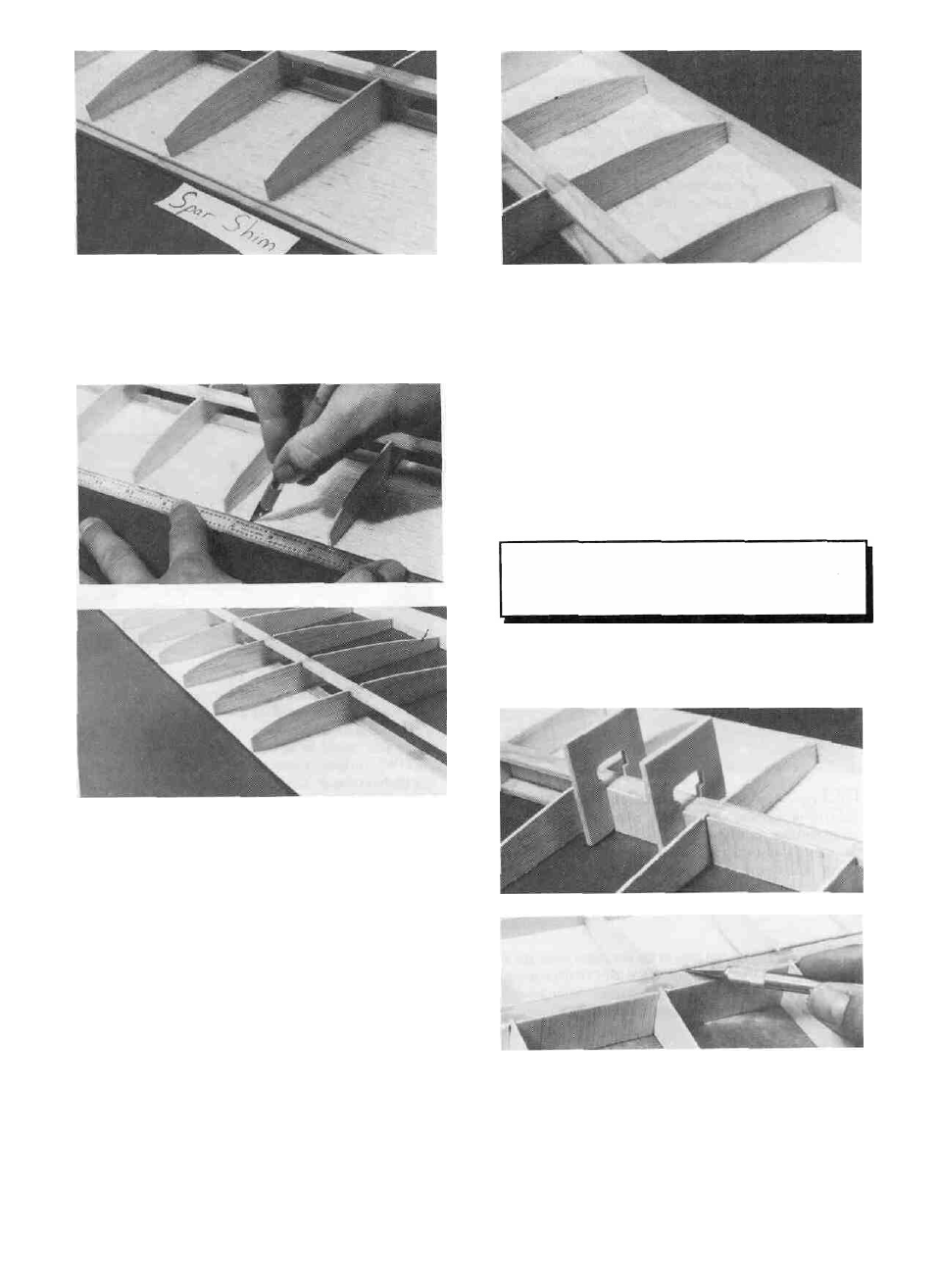

shorter than the panel so you will have to do approx half the ribs

then move the spar down to do the rest of the ribs

D D 10 Unpin the wing panel from the work surface and

hold a metal straight edge against the front of the ribs Allow the

panel to tip up so the front edge of the sheeting is flat on the work

surface and use an Xacto knife to carefully cut the sheeting off

flush with the from edge of the ribs Use a sanding block to

remove any "bumps" but be careful not to sand any dips into the

sheeting or sand the ribs

D D 11 Position a Pre-Shaped Balsa Leading Edge

(SPT 1 W 14) in place against the front of the ribs NOTE: 1 these

leading edges are NOT symmetrical. Refer to one of the section

views on the plans to determine which way they should be

installed Carefully hold the leading edge against one of the end

W2S ribs and note that it is wider than the front of the rib This

is because the 1/16 balsa leading edge top sheeting will be added

later Align the lower surface of the leading edge with the bottom

of the lower LE sheet and glue it in place with a drop of thin CA

Align the other end of the leading edge with the bottom of the

opposite end W2S and glue it with a drop of thin CA Go down

the line and glue the remaining ribs to the leading edge, one at a

time, so you can make sure they are aligned Make sure the LE

sheeting is flush with the bottom of the LE and add CA between

the ribs Do not glue the sheeting to the LE past the last W2S ribs

yet.

IMPORTANT - MAKE SURE THE W I N G

PANEL REMAINS ABSOLUTELY FLAT

DURING THE NEXT STEP!

DD 12 Locate the 1/16" Balsa Shear Webs (SPT1W24)

Trial fit one of the webs in place between the first and second

W2S ribs Glue the shear web in place on the back of t h e spars

using med or thick CA The web should be pressed down against

11