Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 31

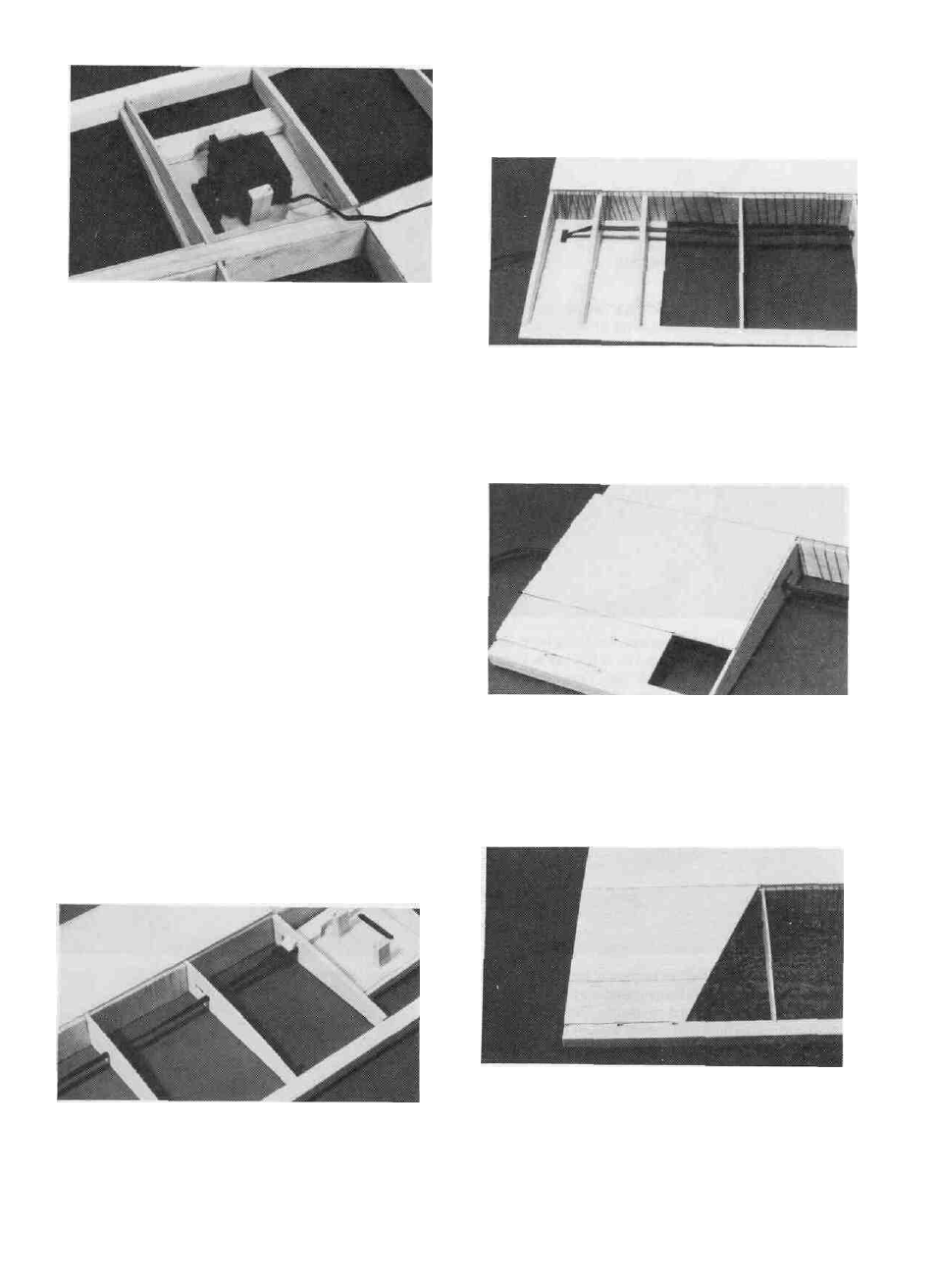

DD 6 Turn the wing right side up and position the aileron

servo on the hatch so the servo horn is centered in the slot Look

down the wing to make sure the servo does not extend past the top

of the ribs II if does you can move the servo forward and enlarge

the slot to accommodate it Put a drop of med or thick CA on one

end of two of the wing servo rails you cut earlier and glue them

in place next to the servo mounting flanges Remove the servo

and add med or thick CA around the rails to securely glue them

in place

removed later if needed Glue a piece of 1/4" balsa triangle stock

around the plug to secure it

DD 11 C u t a s l o t i n t h e b o t t o m s h e e t i n g n e x t t o t h e f i r s t W 1 B

rib for the extension to exit String the extension through the ribs

and out the slot in the bottom sheeting Glue the extension to each

rib with med or thick CA

D D 7 Remove the hatch from the wing and replace the

servo on the rails Drill 1/16" holes in the servo rails for the servo

mounting screws and mount the aileron servo flat against the

mounting plate using the screws provided with the radio

D D 8 Replace the hatch with the servo installed and check

to make sure the servo rails do not extend past the top of the ribs

Sand the rails if necessary The lower the rails and the servo, the

less chance they have of deforming the top wing covering when

it is applied

D D 9 The aileron servo extensions need to be installed

now You will need about 36" of extensions in each wing so

depending on the brand of radio you choose, you may need to join

a couple of smaller extensions If you will have two extensions

plugging together inside the inner panel put a drop of med or

thick CA on the plugs (after they are assembled) to hold them

together forever'

DD 10 Glue the servo end of the extension into the slot in

W3B It needs to be installed there so the aileron servo can be

DD12 Cut a 4" and a 5" piece of 1/16" sheeting for

the top inboard center section out to rib W2B as shown in the

photo Med or thick CA should be used for this step Glue the

5" piece near the spars and cut the 4" piece to fit between the first

piece and the sub TE Glue it in place

DD 13 Cut the sheeting off at an angle from the front of W2B

to within 1/4 of the rear of W 1 B as shown on the plans Sand the

sheeting flush with the W1B rib at the wing root

31