Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 16

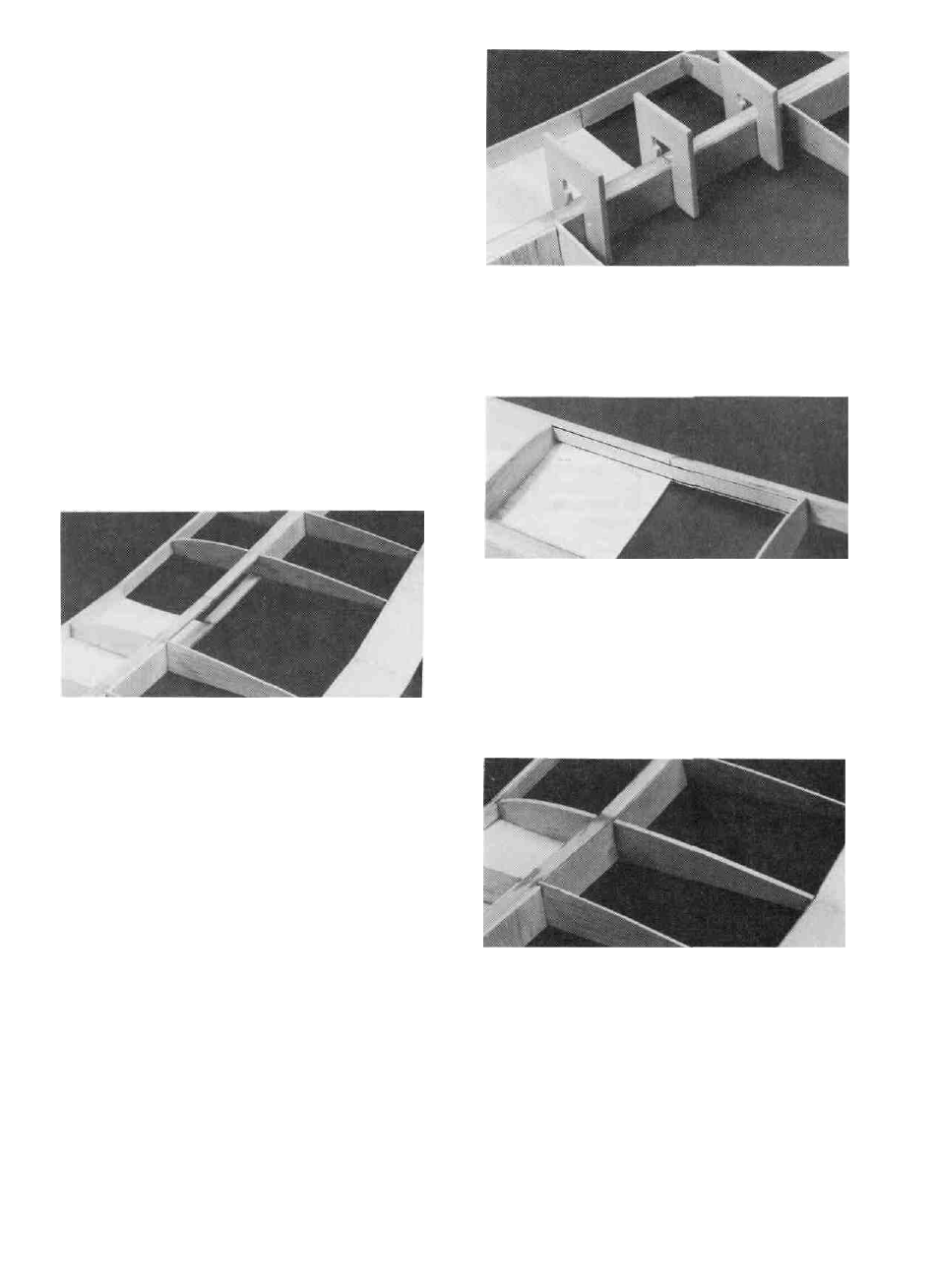

measurement at rib W10S. Use a sanding block to carefully sand

the leading edge, spars and trailing edge to achieve vertical

surfaces on each. Check your progress by occasionally setting

the panel on the plans to make sure you are not sanding any

"sweep" (forward or backward tilt) into the wing. HINT- Set the

panel on an "elevated" building surface an inch or so above the

work surface and use the edge of the elevated surface to hold the

sanding block perpendicular to the work surface as shown in the

photo.

D D 2. With the inner panel flat on the work surface, sand

the leading edge, spars and trailing edge so they are all even and

of the correct length.

both sides of the spars. Use the die-cut C2 clamps (SPT1W22)

to hold everything in place. Wipe o f f any excess glue before it

cures.

D D 3. Test fit the inner and outer panels together over the

plan to make sure the leading edges, spars, and trailing edges all

meet up nicely when the tip panel is blocked up the required

3-1/2" (at the bottom of rib W10S) with the dihedral gauge. Sand

any ends if needed to make everything fit well.

D D 4. With the dihedral gauge in place, Apply med. or thick

CA or epoxy to the leading edge, trailing edge and spar joints to

"tack glue" the two panels together. Hold everything in place

until the glue has cured.

D D 5. Cut the balsa bottom sheeting away (1/32") from the

front of the inner panel spar to clear the polyhedral brace. The cut

should start at the last W2S rib and continue to the end of the spar.

Punch out two of the 1/32" Die-Cut Ply Polyhedral Braces

(SPT1W10) with an "S" embossed on them and test fit them in

place against the front and back of the spars. Sand them if needed

to achieve a good f i t .

D D 7. Locate the two 1/32" Die-Cut Ply Leading and

Trailing Edge Braces (SPT1W10) that were next to the polyhe-

dral braces you used earlier. Test fit them in place and sand them

if needed to make them fit between the rib W2S and W4S. The

LE brace should be at least 1/16" below the top of the LE to allow

for the 1/16" top sheeting, which will be added later. Glue them

in place with med. or thick CA. If the TE brace extends above or

below the surface of the TE, sand it flush.

D D 8. Install ribs W3SA and W3SB (SPT1W02) between

the inner and outer panels using med. or thick CA. A little sanding

may be necessary to achieve a good fit. Use the rib gauge to tilt

the ribs to the proper angle.

D D 6. When satisfied with the fit, apply a generous bead of

epoxy or med. or thick CA to the spars and install the braces on

D D 9. Drill a 13/64" hole down through the hole in the front

wing bolt plate and through the 1/16" bottom sheeting. Lightly

16