Install radio gear – Great Planes Spirit 100 Sailplane Kit - GPMA0550 User Manual

Page 44

D 1. Set the wing so an inner panel is resting on a flat surface.

Any warp (twist) will show up by causing a corner of the panel to

rise off of the work surface.

D 2. To remove the warp, gently twist the wing in the opposite

direction while a helper glides an iron or heat gun over the

covering on both the top and the bottom of the panel to re-shrink

the covering. Hold the twist until the covering cools and then

recheck for warps. It may take several trys to get a warp out but

it is worth it as you will end up with a sailplane that flies straight

and true and responds to air currents like a high performance

sailplane should.

D 3. Follow the same procedure to check all four wing panels

and then go back and double check them. Sometimes you put a

warp in one panel while trying to fix another. You should also

look at the tail surfaces as they too can warp.

HINGE THE CONTROL SURFACES

D 1. Lay the rudder and elevator on the plans and mark on the

leading edge of each part the locations of the hinges. Now use a

sharp hobby knife to cut slits in the covering at the hinge

locations. Trial fit the hinges to make sure you have "found" the

slots which you previously cut. In the same manner, slit the

covering at the hinge locations in the stab and fin TE.

D 2. Follow the instructions that came with your particular

hinges but keep this in mind: When gluing the hinges it is

important plenty of glue gets inside the hinge slot.

D 3. Use Monokote strips or a good thin tape to hinge ailerons

and flaps. Put one strip the entire length of the aileron or flap and

put some small strips on the other side of the "hinge".

plans as a reference for positioning the horns (Rudder on the left,

elevator on the bottom). Drill two 3/32" holes through the control

surfaces using the control horns as guides. Remove the control

horns and harden the balsa in the area of the control horns (on

both sides of the control surfaces) by poking several holes with

a pin, then apply thin CA glue and allow it to soak in and cure.

Wipe off any excess glue before it cures. Redrill the holes if

necessary. Mount the control horns with the 2-56 x 5/8" Ma-

chine Screws (SCRW002) and the Nylon Nutplates which were

attached to the horns.

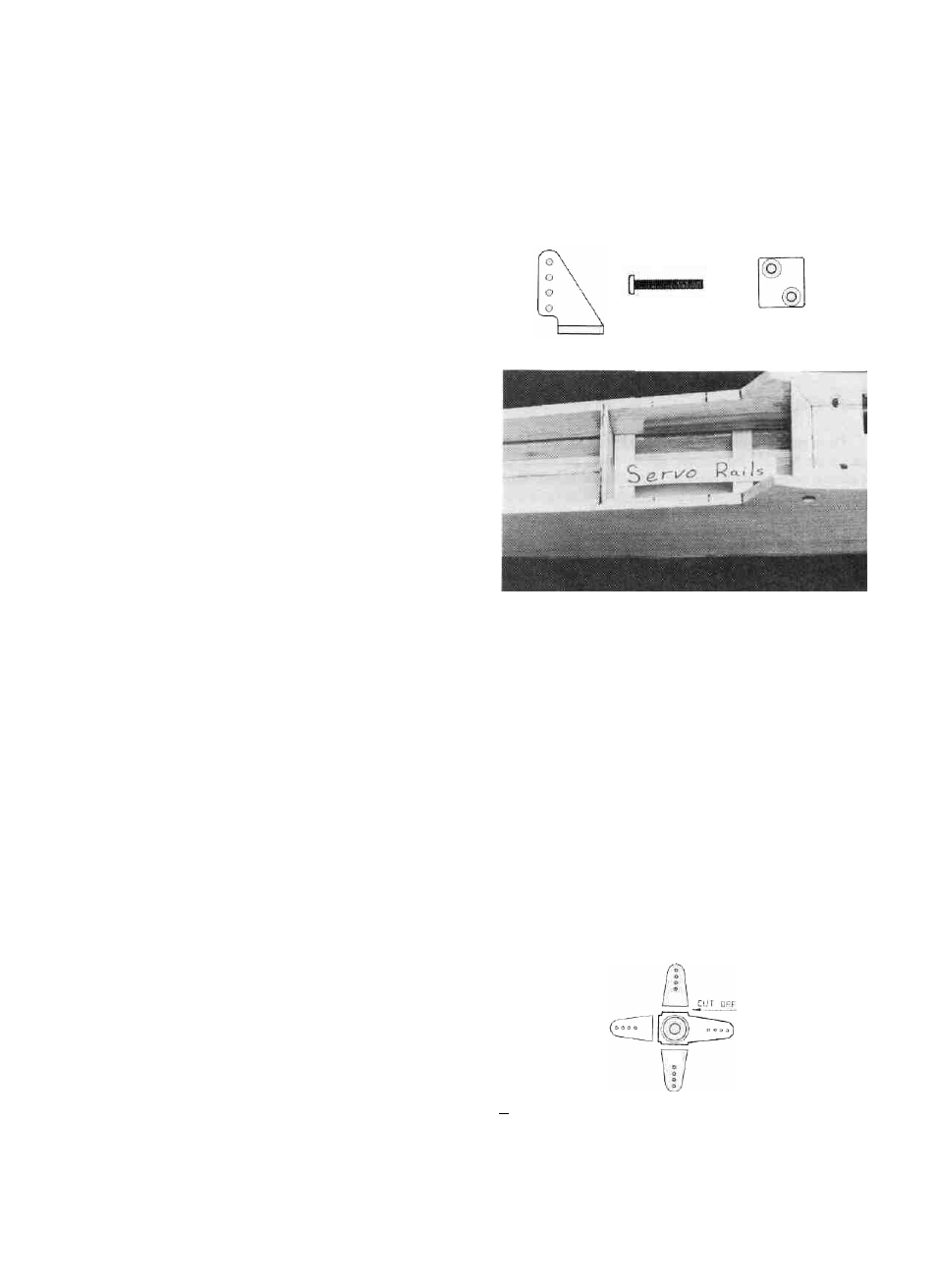

D 3. Cut two 1/4" x 3/8" Basswood Servo Rails (SPT1F14)

2-1/16" long. Slide them into the slot between formers F4 and F5

(Cut two more for between F3 and F4 if you are installing

spoilers). Slide one all the way forward and glue it in place with

med. or thick CA. Slide the other servo rail all the way to the back.

Do not glue it yet! Position one of your servos in place and use

it to position the rear servo rail. Do not push the rear servo rail

up light against the servo but rather leave about a 3/32" gap

between the servo "body" and the rear servo rail. This will give

you enough room to put the servos in and out without removing

the rails. Glue the rear servo rail in place.

INSTALL RADIO GEAR

D 1. Read and follow the instructions that came with your

radio to install or charge the batteries and get the servos ready for

mounting. Plug the servos and the battery pack into the receiver

and turn on the transmitter first and then the receiver. Adjust the

trim levers to their neutral positions and allow the servos to return

to their neutral positions.

D 2. Tack glue the Nylon Control Horns (NYLON03) in

place on the rudder and elevator with a drop of thin CA. Use the

D 4. Position the rudder and elevator servos together in the

middle of the rails and mark where the holes for the servo

mounting screws should be drilled. Remove the servos and drill

1/16" holes where the marks are. Install the servos, with the wires

exiting toward the receiver using the servo mounting screws that

came with the radio.

D 5. Cut three "arms" off of two X-type servo horns using wire

cutting pliers or a razor saw as shown in the sketch. Install the

44