AERCO Electronic Controls System (ECS) User Manual

Page 46

Electronic Control System (ECS) and Type CXT-E Valve

7. TROUBLESHOOTING

Page 46 of 82

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288

VD2: 02/28/14

OMM-0003_0D

AC-105

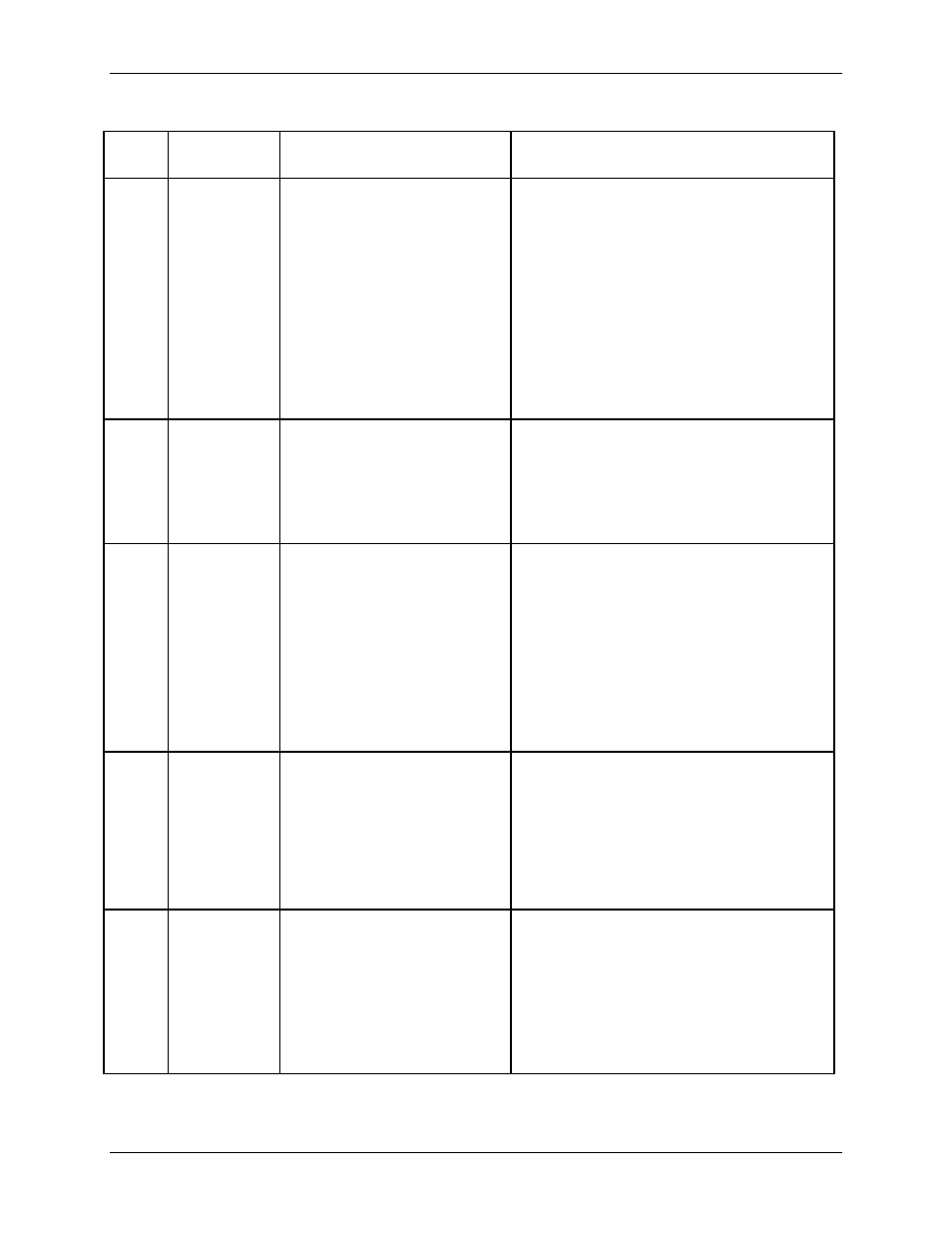

Table 7-2. Troubleshooting – Electronic Control System (ECS)- Continued

NO.

FAULT

INDICATION

PROBABLE CAUSE

CORRECTIVE ACTION

T13

Wide

fluctuations

in outlet

water

temperature

under low

flow

conditions.

1. Outlet Temp Sensor

connected to Temp

Controller is intermittent

2. Obstruction in Flow

Sensor.

3. Inlet Orifice worn or not

properly seated.

4. Recirculation Pump

failure.

1. Replace Outlet Temp Dual Sensor

at Heater outlet port.

2. Clean or refurbish Flow Sensor per

Section 6.

3. Replace Orifice or reseat in required

nozzle position.

4. Replace Recirculation Pump.

T14

Temp

Controller

displays

Loop break

(Lbr) error

message

1. Outlet Temp Sensor not

connected.

2. Outlet Temp Sensor

defective.

1. Ensure Temp Sensor connector

plug is securely connected.

2. Replace Outlet Temp Dual Sensor

installed at Heater outlet port.

T15

Outlet water

temperature

above Over-

Temp Limit,

but Solenoid

(Dump)

Valve does

not open.

1. Disconnected or

defective Solenoid

2. Defective Over-Temp

Switch

1. Verify that 24 VDC is present at

Solenoid plug between leads

103(+) and 104 (-).

If voltage is present and Solenoid is

connected, it is defective and must

be replaced. If 24 VDC is not

present, go to item 2.

2. Replace Over-Temp Switch.

T16

Inconsistent

temperature

reading

1. Sensor wire polarity

reversed.

2. Faulty Sensor.

1. Check polarity of TC wiring; J

Thermocouple Standard Wiring:

-- Red wire is negative.

-- White wire is positive.

(Refer to Wiring Diagram B-2)

2. Replace TC Sensor.

OPEn

Secondary

Input is

missing.

g

1. Flow meter not powered.

2. Failed feedforward sensor.

3. Unplugged connection to

feedforward sensor.

1. Check power LED of Flow meter. Apply

power or replace.

2. Replace feedforward sensor.

3.

Ensure proper sensor connections.